Metal/graphene composite material and preparation method thereof

A composite material and graphene technology, applied in coatings and other directions, can solve problems such as environmental pollution, long production cycle, and interface impact, and achieve the effects of avoiding energy waste and environmental pollution, high production efficiency, and optimized performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

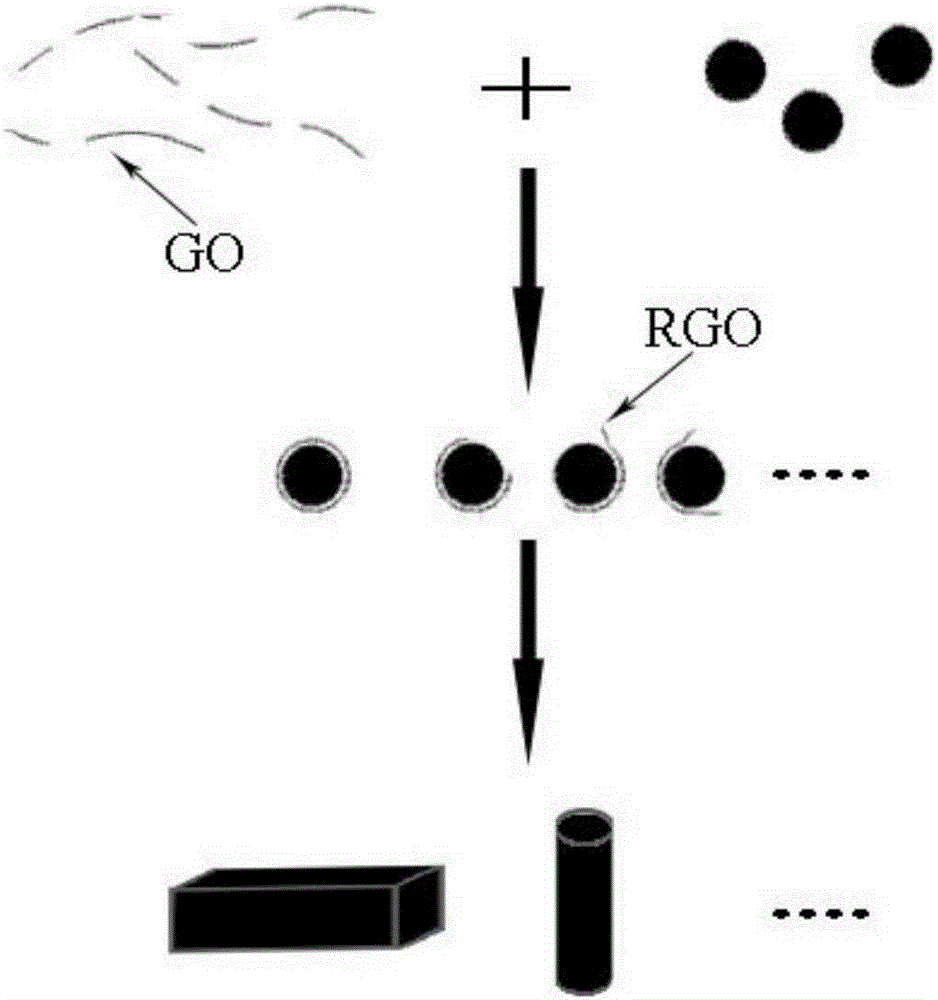

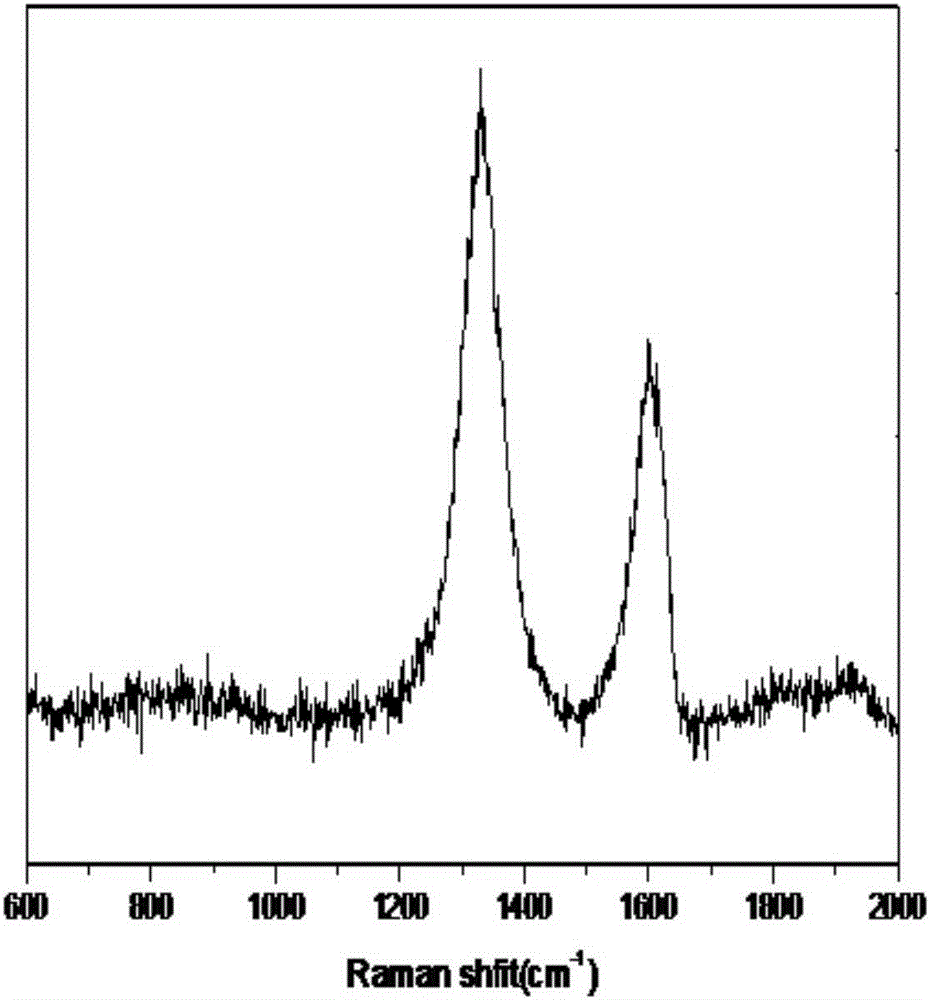

[0040] The present embodiment relates to the preparation method of graphene / aluminum composite material, and described method comprises the steps:

[0041] Step 1: preparing a graphene oxide solution: preparing a graphene oxide aqueous solution by an improved Hummers method, and adjusting the concentration of the graphene oxide aqueous solution to 0.2 mg / ml by adding deionized water.

[0042] Step 2: adjust the pH value of the graphene oxide aqueous solution: take 25ml of the graphene oxide solution described in step 1, and adjust the pH of the solution to 4 by adding 0.1mol / L dilute hydrochloric acid or 0.1mol / L NaOH solution.

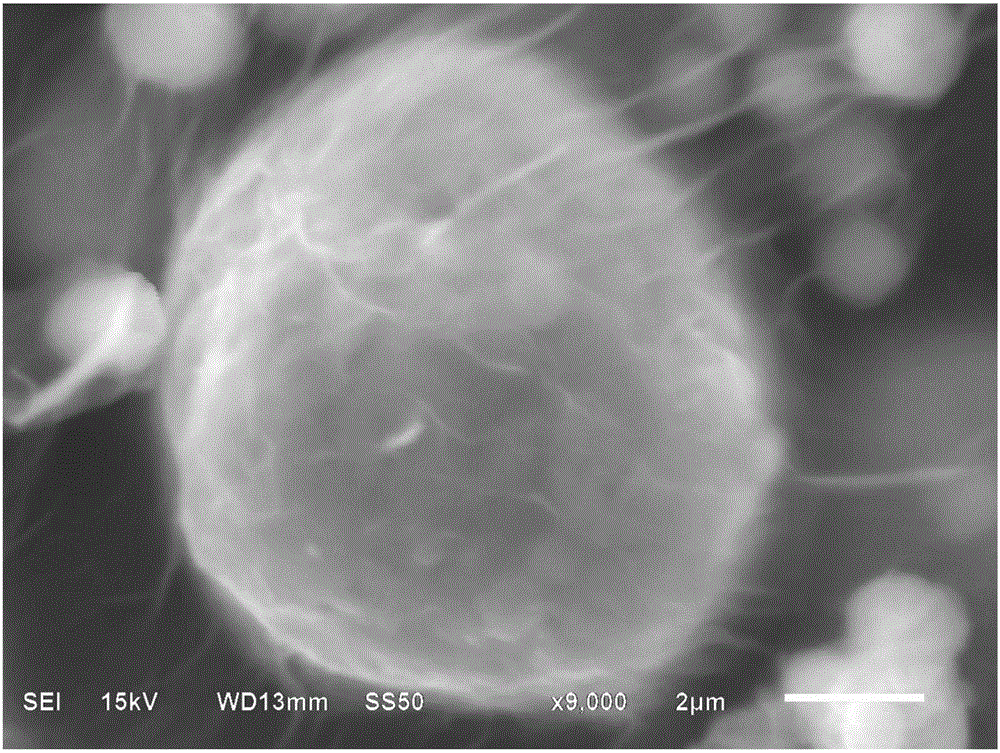

[0043] Step 3: At room temperature, take 1 g of aluminum powder with a particle size of 20 μm and add it to the graphene oxide aqueous solution with a pH of 4 as described in step 2. The aluminum particles and graphene oxide are fully mixed and reacted by magnetic stirring. The reaction time is 24 hours A uniformly dispersed graphene / aluminum particle...

Embodiment 2

[0047] The present embodiment relates to the preparation method of graphene / iron composite material, and described method comprises the steps:

[0048] Step 1: preparing a graphene oxide solution: prepare a graphene oxide aqueous solution by an improved Hummers method, and adjust the concentration of the graphene oxide aqueous solution to 0.5 mg / ml by adding deionized water.

[0049] Step 2: adjust the pH value of the graphene oxide aqueous solution: take 50 ml of the graphene oxide solution described in step 1, and adjust the pH of the solution to 5 by adding 0.1 mol / L dilute hydrochloric acid.

[0050] Step 3: At room temperature, take 1 g of iron powder with a particle size of 15 μm and add it to the graphene oxide aqueous solution with a pH of 5 as described in step 2. The iron particles and graphene oxide are fully mixed and reacted by magnetic stirring, and the reaction time is 0.5 h, A uniformly dispersed graphene / iron particle mixture obtained by in-situ reduction of g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com