Intelligent Nano Dynamic Centrifugal Rotary Separation Device

A rotary separation and nano technology, applied in grain processing and other directions, can solve the problems of stable separator and possible unfavorable operation, low separation efficiency, and inability to solve the problem of secondary entrainment of powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

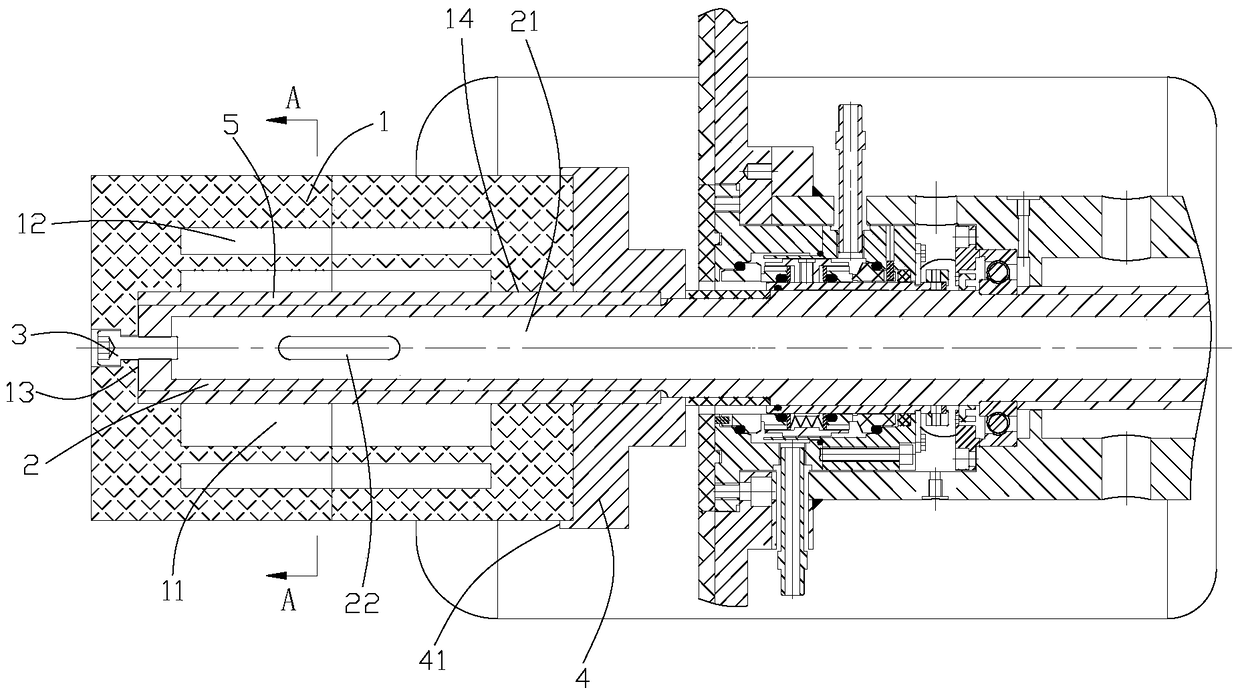

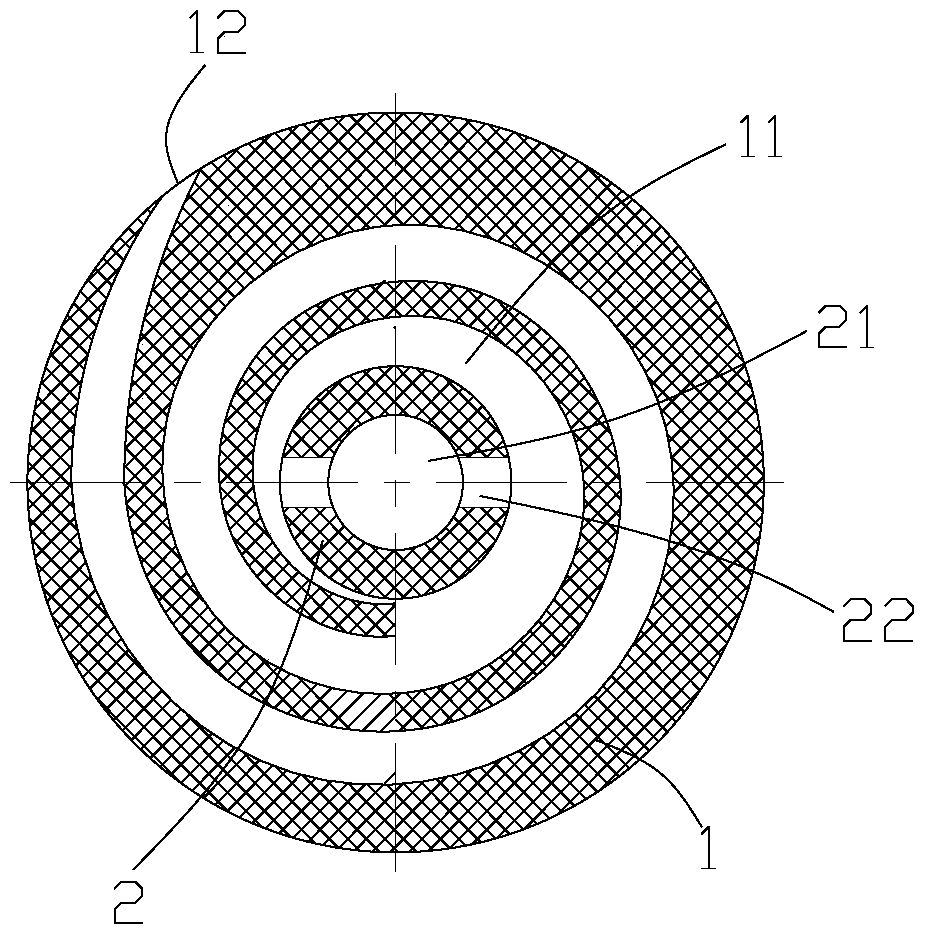

[0017] Combine below figure 1 , figure 2 The intelligent nanometer dynamic centrifugal rotating separation device of the present invention is introduced in detail, including a separation cylinder 1 arranged in the grinding barrel of a sand mill, a cavity 11 is formed inside the cylinder, and the axial ends of the cylinder are closed to drive the cylinder to rotate The hollow shaft 2 is axially inserted into the cavity, and the cavity communicates with the inner cavity 21 of the hollow shaft; preferably, the cavity communicates with the inner cavity of the hollow shaft through several discharge holes 22 arranged on the hollow shaft; A vortex 12 is provided inwardly from the outer wall of the cylinder, and the vortex communicates with the cavity. When the material is ground by the grinding medium in the grinding area of the grinding cylinder, it gathers in the separation area under the action of the pressure in the grinding cylinder. The material in the separation area enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com