Internal-expanding-type tubular busbar intermediate joint

A technology of intermediate joints and tube busbars, applied in the direction of connecting contact material, connection, conductive connection, etc., can solve the problems of gaps between intermediate joints and tube busbars, affecting conductive performance, and lack of self-locking function, so as to increase the contact area, The effect of good electrical conductivity and not easy to heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention are described in detail below, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0015] Unless expressly stated otherwise, throughout the specification and claims, the term "comprise" or variations thereof such as "includes" or "includes" and the like will be understood to include the stated elements or constituents, and not Other elements or other components are not excluded.

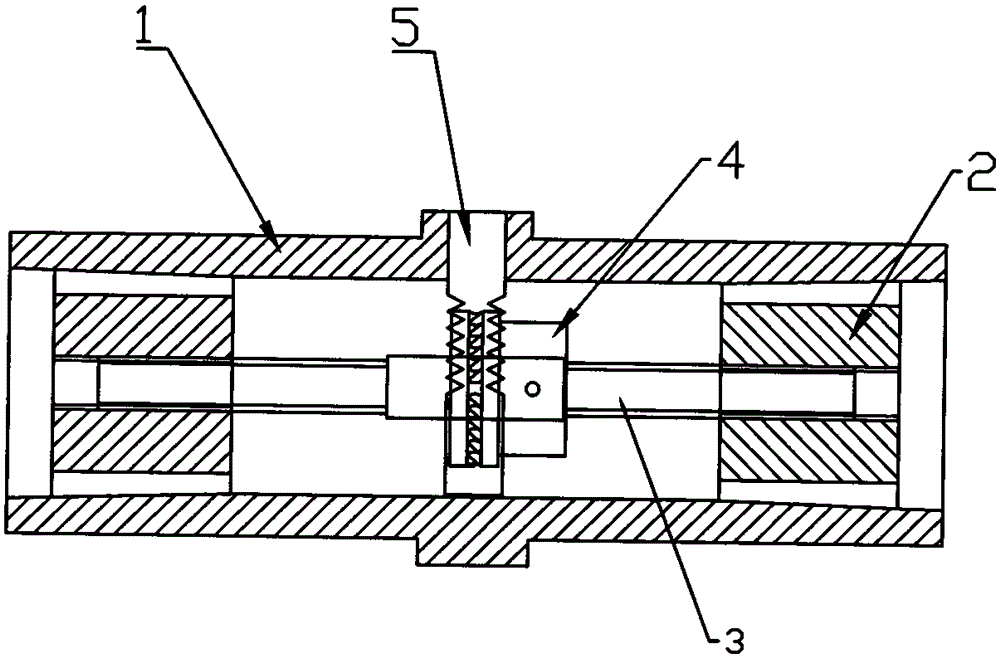

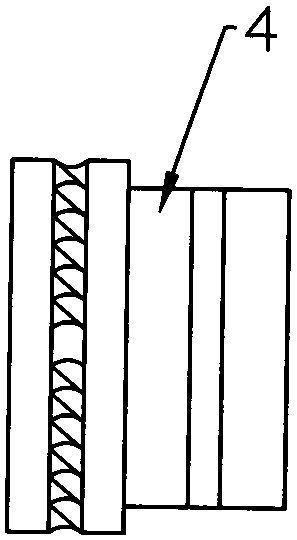

[0016] like Figure 1-2 As shown, the internal expansion pipe bus intermediate joint is composed of an intermediate joint 1, an expansion joint 2, a double-ended screw 3, a turbine 4, and a worm 5; the two ends of the intermediate joint 1 are respectively built with expansion joints 2; the double-ended Both ends of the screw 3 are respectively engaged with the central threaded hole of the expansion joint 2; the central part of the double-ended screw 3 is fixedly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com