Method for detecting biological membrane ageing state in sewage and wastewater processing system

A technology for processing systems and aging states, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as the inability to detect the aging state of biofilms, and achieve the effects of strong practicability, improved efficiency, and intuitive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

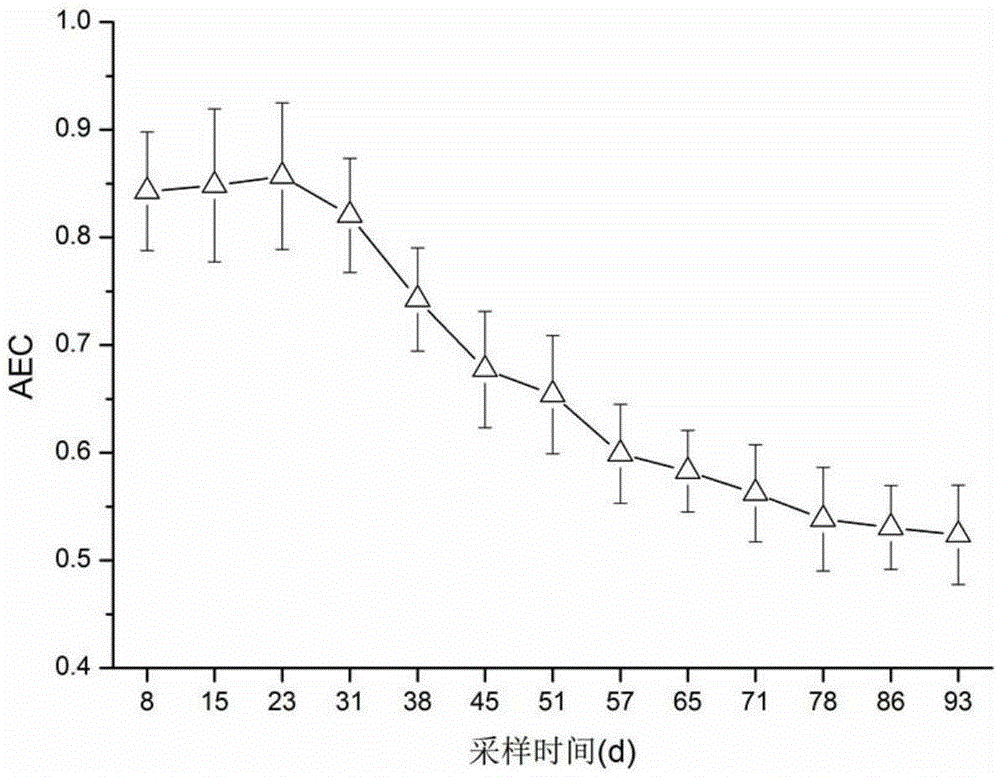

[0036] In this embodiment, the detection of the aging state of the soft filler biofilm in a certain municipal sewage aerobic treatment system is carried out. The influent water quality of the system is: pH 7.17-7.85, chemical oxygen demand 340-520mg / L, ammonia nitrogen concentration 30-50mg / L, total nitrogen concentration 60-90mg / L, total phosphorus concentration 3.2-6.6 mg / L, conductivity 580~730μS / cm.

[0037] The specific operation for detecting whether the biofilm is aging is as follows:

[0038] Step 1. Take out the biofilm from the sewage treatment system: Take out the soft packing from the same depth of the sewage tank, cut the biofilm from the surface of the soft packing, put it in a -20°C freezing sampling box, and quickly bring it back for subsequent experiments ;

[0039]Step 2, biofilm pretreatment; use sterile water to make a 1000mg / L suspension of biofilm; take 2.5mL of biofilm suspension, add an equal volume of pre-cooled 0.6mol / L perchloric acid solution, and...

Embodiment 2

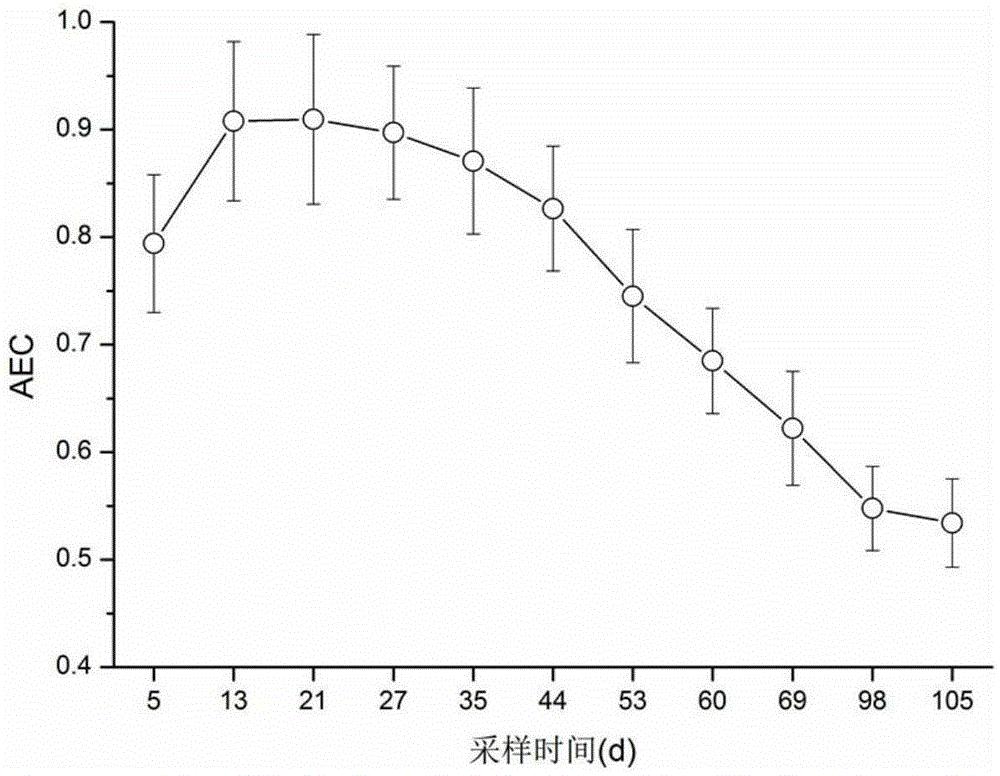

[0044] In this example, the detection of the aging state of the suspended filler biofilm in the comprehensive wastewater treatment system of a certain oxidation industrial park is carried out. The influent water quality of the system is: pH 7.08~7.52, chemical oxygen demand 1200~2540mg / L, ammonia nitrogen concentration 1.54~6.80mg / L, total nitrogen concentration 35~65mg / L, total phosphorus concentration 11.2~ 20.6mg / L, conductivity 12580~16340μS / cm.

[0045] The specific operation for detecting whether the biofilm is aging is as follows:

[0046] Step 1. Take out the biofilm from the sewage treatment system: After taking out the filler from the sewage tank, scrape the biofilm off the surface of the suspended filler, put it in a cryotube, freeze it in a liquid nitrogen bottle, and bring it back for experimental analysis;

[0047] Step 2, biofilm pretreatment; use sterile water to make a 200mg / L suspension of the biofilm; take 10mL of the biofilm suspension, add an equal volume...

Embodiment 3

[0052] In this example, the detection of the aging state of the suspended filler biofilm in a slightly polluted water source and aerobic water treatment system is carried out. The water quality of the system is: pH 7.66-8.35, chemical oxygen demand 14.3-19.6mg / L, ammonia nitrogen 0.88-2.91mg / L, UV 254 5.8~6.9m -1 , UV 254 The numerical value represents the ultraviolet absorbance under the unit cuvette light path at a wavelength of 254nm, reflecting the amount of humic macromolecular organic substances and aromatic compounds containing C=C double bonds and C=O double bonds naturally existing in water.

[0053] The specific operation for detecting whether the biofilm is aging is as follows:

[0054] Step 1. Take out the biofilm from the sewage treatment system: After taking out the filler from the sewage tank, scrape the biofilm off the surface of the suspended filler, place it in a -20°C frozen sampling box, and quickly bring it back to the laboratory;

[0055] Step 2, biofi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com