Granularity detection method

A detection method and particle size technology, applied in the direction of particle size analysis, particle and sedimentation analysis, measuring devices, etc., can solve the problems of no particle dispersion treatment, poor particle size authenticity, complex structure, etc., to achieve fast testing speed and easy operation. , the effect of testing a wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

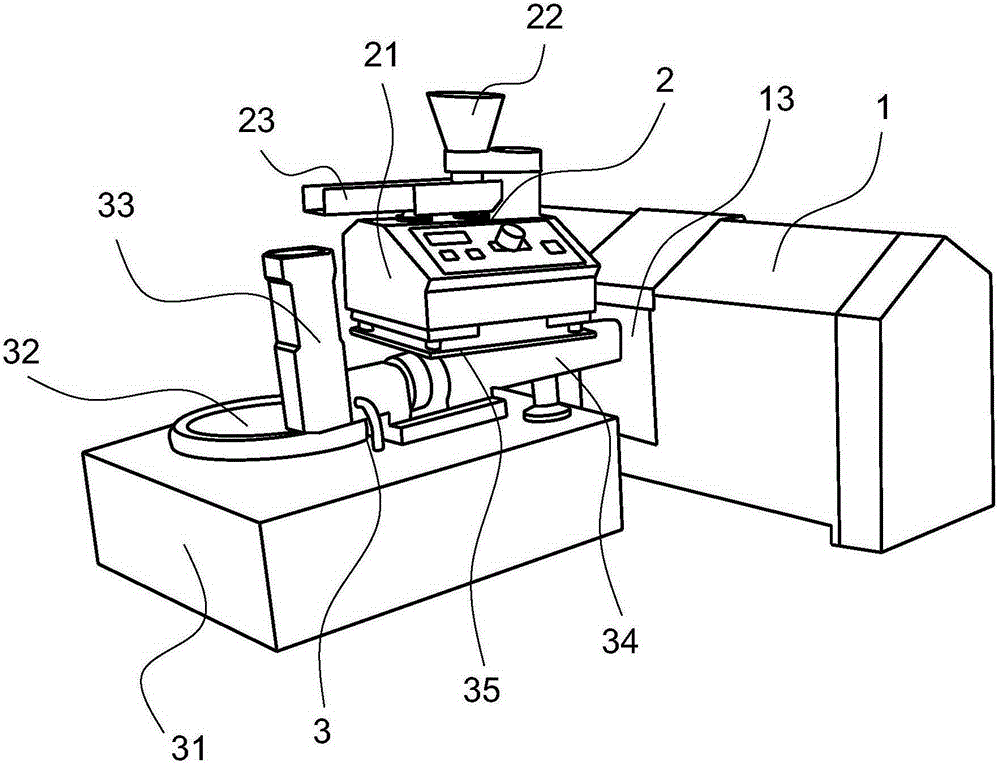

[0026] Figure 1-5 It is a structural schematic diagram of an embodiment of the present invention, which includes a laser diffraction system 1 , a sampling system 2 , a dispersion system 3 and a vacuum cleaner 4 .

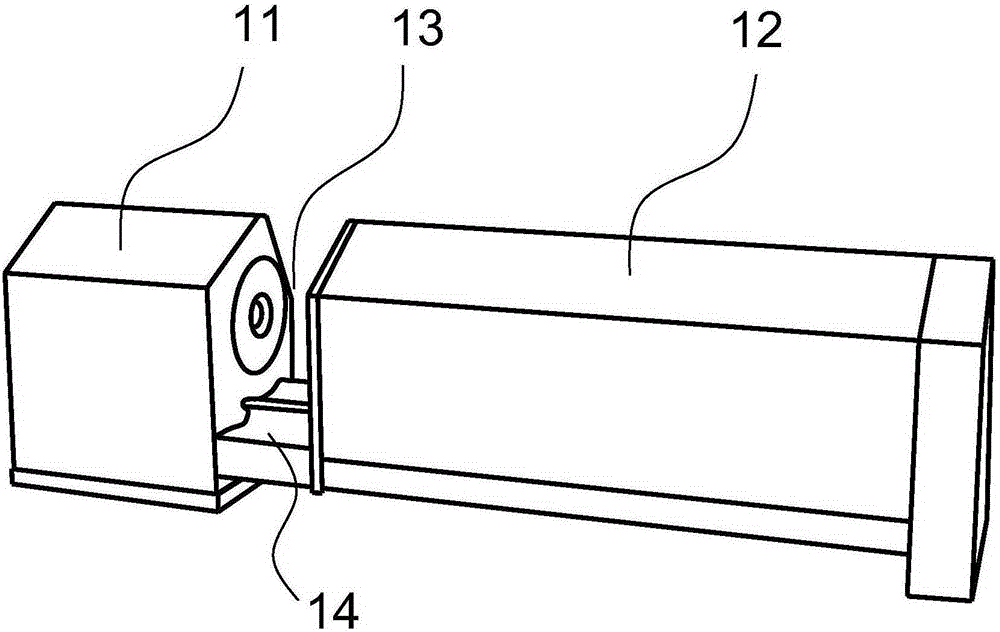

[0027] The laser diffraction system 1 comprises a laser system 11, a receiving system 12 and a test area 13. The test area 13 is located between the laser system 11 and the receiving system 12 and is an open area. There is a base 14 under the test area 13, the laser system 11 and the receiving system. The system 12 is respectively arranged on the two ends of the base 14, the laser system 11 and the receiving system 12 move relative to the base 14, so that the size of the test area 13 can be adjusted, and the below of the test area 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com