Novel floating heat exchanger equipment

A floating, heat exchanger technology, applied in the direction of mobile ducted heat exchangers, heat exchange equipment, heat exchanger types, etc., can solve the problem that the volume cannot be effectively utilized, the heat exchange effect cannot be achieved, and the heat transfer coefficient of the equipment is low. and other problems to achieve the effect of saving project cost, solving scale phenomenon and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

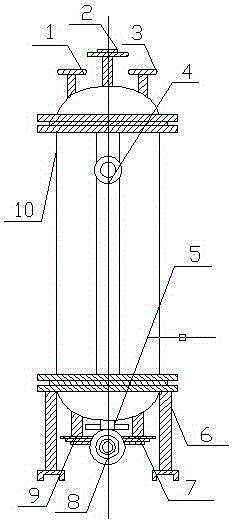

[0020] Example: such as figure 1 As shown, the present invention provides a new type of floating heat exchanger equipment, including a safety valve 1, a hot water port 2, a branch pipe interface 3, a pressure gauge 4, a water separation reactor 5, a support frame 6, and condensed water 7 Outlet, sewage outlet 8, steam inlet 9, shell 10; a safety valve 1 is set on the top of the shell 10 and the safety valve 1 is embedded in the surface of the shell 10; a hot water port 2 is set on one side of the safety valve 1, and the branch pipe interface 3 The hot water outlet 2 is symmetrically arranged with the safety valve 1; the bottom of the shell 10 is equipped with a sewage outlet 8 and a steam inlet 9 is installed on the side of the sewage outlet 8; the condensed water outlet 7 is located on the side of the sewage outlet 8 and the condensed water outlet 7 It is arranged symmetrically with the steam inlet 9; a water separation reactor 5 is installed on the top of the sewage outlet 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com