[0003]The technical problem to be solved by the present invention: to overcome the energy that the existing thermal power plant relies on to operate, the carbon material swept in from the outside of the power plant can be burned in the boiler to generate potential energy and drive the generator to operate through the

transmission system Then the potential energy is converted into electric energy by the generator. In hundreds of years, the only

energy resources on the earth will be exhausted, so that future generations will have no energy resources available and there will be defects in polluting the environment. Invented a rack system,

digital control system, The integrated generator set for power generation and supply (hereinafter referred to as the present invention) composed of a

starter motor system, a

fluid power guarantee system, a condensed matter

energy storage system, a potential

energy transfer system, a dynamic

rotation control system, a cooling system, a

lubrication system, and a potential energy conversion electric

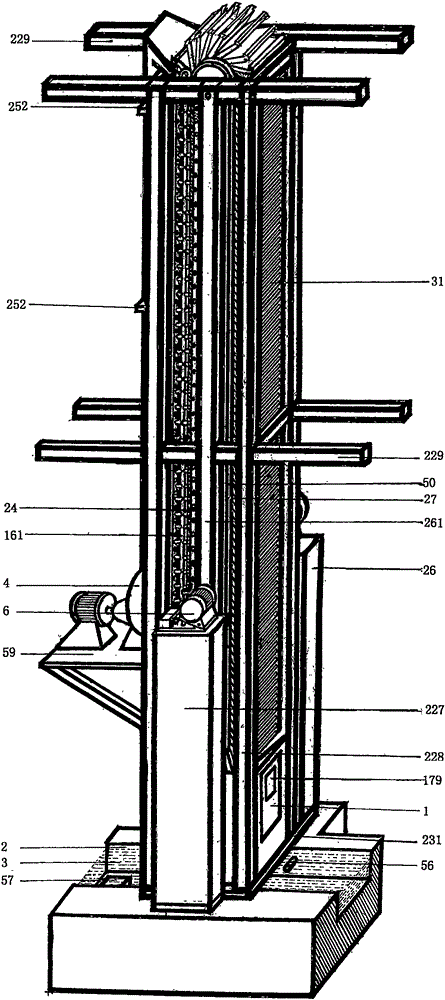

energy system (hereinafter referred to as the present invention). The invented frame system is equipped with left force column, right force column, bearing, potential box support plate, control box support plate, left

pulley block, right

pulley block,

pulley, pulley shaft, guard plate, left lower gear, left middle gear , left upper gear, right lower gear, right middle gear, right upper gear, cabinet, seat frame, corner column, pump column

firmware, adjacent bar and

machine base are all mechanical parts and electrical appliances in the system. Components including water, gear lubricating oil and cooling water are assembled together to form a frame

structure system of a generator set. The

digital control system is equipped with a

microcomputer controller, a left

pressure sensor, a right

pressure sensor, a speed sensor, and an

oil temperature sensor. ,

water temperature sensor,

cooling water temperature sensor, cooling

water pressure sensor,

oil pressure sensor, oil

level sensor and operation panel are a kind of system which can always be integrated with the whole working procedure of the present invention from the start-up stage, program replacement and re-entry into normal operation. All electrical components and electronic components communicate with each other and transmit information to each other, and can always detect, monitor, display, adjust, and control the operating status and working efficiency of each electrical component,

electronic component, and mechanical component in the system. The

automatic control and self-protection of the operating state in the system can always ensure that the

operating temperature in the system is within the set value range, and the speed,

voltage, power supply and frequency of the generator operating can always be guaranteed to be within the

normal range, so that the system can always be automated The working mode is implemented to ensure that the system can always run safely and reliably and provide timely power supply to the

numerical control system. The

starter motor system is equipped with a

starter wheel, a bouncer, a bolt tongue, a reed, an

electromagnetic coil, a

machine spring, a bolt tooth and a starter motor. The present invention can start the whole operation system in the start-up phase for the mechanical and electrical components of the early stage operation. The

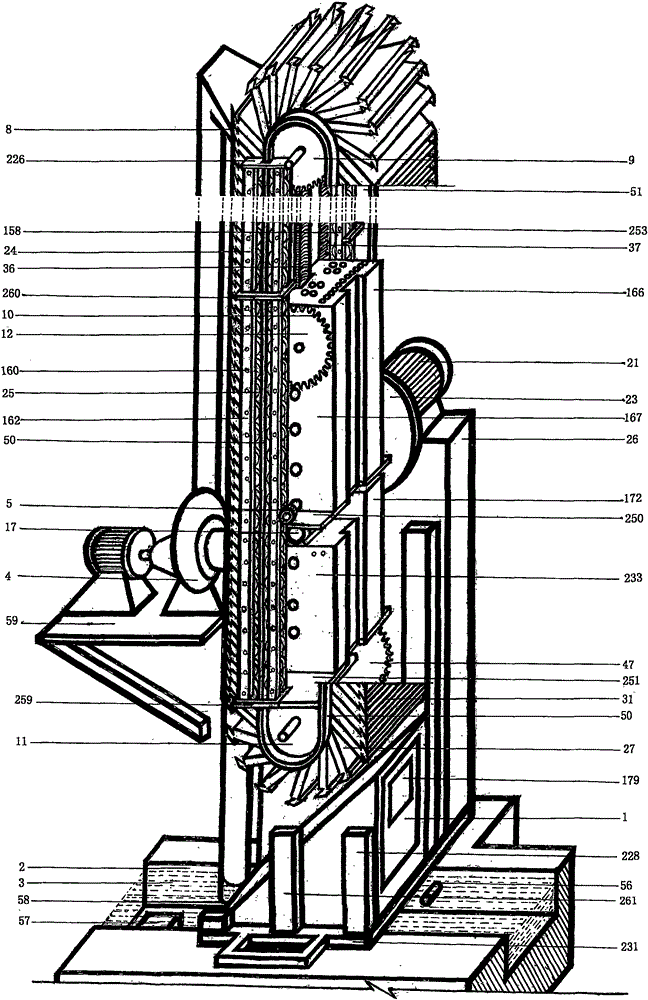

fluid power guarantee system is equipped with

water tanks, water, water heaters, water outlets, centrifugal pumps, water inlets and pump pallets. In the invention, the

centrifugal pump in the system can always lift the water in the water tank upwards and transport it to the upper end of the load-bearing box box group and the water outlet in the whole working process from the start-up stage, program replacement and normal operation. In a load-bearing box, the gravity that enables water to accumulate in the load-bearing box group into a condensed state ensures that the aggregated gravity of the water that is hoarded in the load-bearing box group in a condensed state remains constant. Including the potential energy guarantee system, the condensed matter

energy storage system is equipped with load-bearing boxes, box chains, upper left co-wheels, upper right co-wheels, lower left co-wheels and lower right co-wheels. The incoming water supplied by the

momentum of power advancement enables the water to accumulate in the load-bearing box group into a condensed state of gravity, and with the operation of the system, the water accumulated in the load-bearing box group in a condensed state accumulates Gravity moves vertically downward at a speed of 1cm / s according to the natural law that the force is always moving vertically downward. It can also transfer the force falling potential energy and inertial potential energy generated during the vertical downward movement at a speed of 1cm / s to the generator. The gravity source includes the potential energy condensed energy storage system, and the potential energy

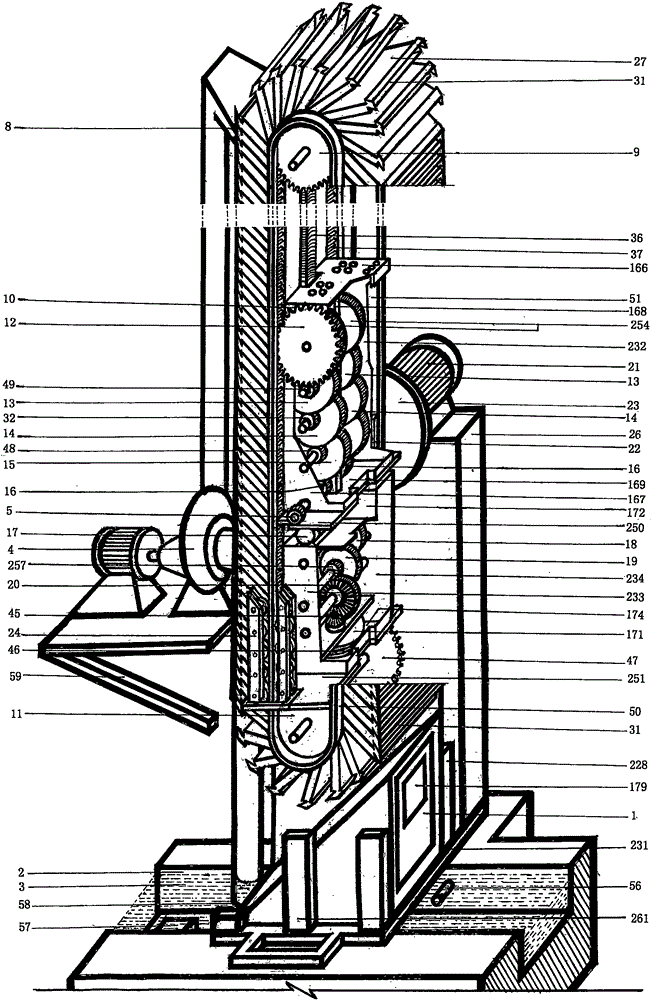

transmission system is equipped with a potential gear box, a left plate of the box, an inner wall of the box, a right plate of the box, a bearing, a plum blossom left wheel, a plum blossom right wheel, a plum blossom tooth, a potential wheel, and a potential two The wheel, the third wheel, the fourth wheel, the fifth wheel, the sixth wheel, the seventh wheel, the

hair shaft wheel, the oil pan and the oil return

pipe are a kind of oil that can always be stored in a condensed state in the load-bearing box group The aggregate gravity of water in the state moves vertically downward at a speed of 1 cm / s according to the natural law that the force is always moving vertically downward, and the force falling potential energy and inertial potential energy generated during the process of moving vertically downward at a speed of 1 cm / s A potential

energy transfer system that converts torque and rotational speed to drive the generator to operate. The dynamic

rotation control system is equipped with a controlled motor, a controlled gear box, a box front plate, a box rear plate, bearings, a shaft control wheel, a control wheel, and a control wheel. Two-wheel, three-wheel control, four-wheel control, five-wheel control, trapezoidal threaded disc, disc spindle, tapered wheel, trapezoidal threaded teeth, oil control pan and oil control return

pipe are a program replacement and During the whole working procedure of its normal operation, it can always control the O-shaped box chain ring, including the running speed of each

momentum wheel, which can always match the running speed of the generator, ensuring that it is stored in the load-bearing box group The aggregated gravity of water in a condensed state can only move in a straight line at a speed of 1 cm / s during the vertical downward movement at a speed of 1 cm / s, ensuring that the

centrifugal pump moves forward in every 1 second with the state of fluid and power advancement. The

water transfer volume in a load-bearing box at the water outlet matches the water-

carrying capacity of a load-bearing box passing through the water outlet every 1s, so that the accumulated weight of the water that is hoarded in the load-bearing box group in a condensed state Always keep the same, to ensure that the generator in the system can always obtain the force drop potential energy and inertial potential

energy matching the rated power or the converted torque and speed, to ensure that the output power of the generator can always be obtained without the participation of the frequency converter

Control system with stable

voltage, stable current, stable frequency, cooling system with cooling pump, cold suction

pipe, cooling

water heater, air pressure tank, cold

pressure pipe, cooling water, cold delivery main pipe, cold delivery pipe a,

heat exchanger a, cold return pipe a, cold transport pipe b,

heat exchanger b, cold return pipe b, cold transport pipe c,

heat exchanger c, cold return pipe c, cold transport pipe d, heat exchanger d, cold return pipe d. Cold delivery pipe e, heat exchanger e, cold return pipe e, cold delivery pipe f, heat exchanger f, cold return pipe f, cold delivery pipe g, heat exchanger g, cold return pipe g, cold delivery pipe h, heat exchanger h, cold return pipe h, cold delivery pipe j, heat exchanger j, cold return pipe j, cold delivery pipe k, heat exchanger k, cold return pipe k, cold delivery pipe m, heat exchanger m, cold return pipe m, cold delivery pipe n, heat exchanger n, cold return pipe n, cold delivery pipe i, heat exchange pipe, cold return pipe i, cold return main pipe, cold

water pipe, cold radiator and cooling electric fan It is a kind of forced cooling method to control the

heat energy generated by each driving wheel and bearing in the gear box during operation, and control the

heat energy generated by each control wheel and bearing in the gear box, including the trapezoidal thread teeth during operation. It is a cooling system that absorbs the

heat energy generated by its generator during operation and dissipates heat through a cold radiator. The lubricating system is equipped with a lubricating

oil pump, oil suction pipe, oil

pool, oil injection hole, oil

discharge pipe, oil heater, Observation window, gear lubricating oil,

oil filter, oil radiator, oil delivery pipe, oil electric fan, chain oil timing valve, shaft oil timing valve, oil delivery main pipe, pressure limiting valve, chain injection

branch pipe, bearing injection

branch pipe, oil return main pipe ,

gear tooth nozzle a,

gear tooth nozzle b,

gear tooth nozzle c, gear tooth nozzle d, gear tooth nozzle e, gear tooth nozzle f, gear tooth nozzle g, bearing nozzle a, bearing nozzle Tube b, bearing nozzle c, bearing nozzle d, bearing nozzle e, bearing nozzle f, bearing nozzle g, bearing nozzle h, bearing nozzle i, bearing nozzle j, bearing nozzle k, bearing nozzle

Pipe L, bearing nozzle m, bearing nozzle n, bearing nozzle z, bearing nozzle o, bearing nozzle p, bearing nozzle q, bearing nozzle r, bearing nozzle s, bearing nozzle t, bearing nozzle Tube u, burst tube a, burst tube b, burst tube c, burst tube d, burst tube e, burst tube f, burst tube g, burst tube h, burst tube i, burst tube j, burst tube k, burst tube m , point injection pipe n, left point injection pipe group and right point injection pipe group are a kind of forced

lubrication method that sends gear lubricating oil from the lubricating

oil pump to each oil delivery pipe in the system, and then sends oil spray nozzles and point injection ports on the top of each oil delivery pipe to each lubricating oil. Point injection and point injection of gear lubricating oil, so that the friction surfaces of the bearings and other transmission parts of each pair of gears in the system are well lubricated, reduce the friction work loss and

mechanical wear of each transmission part, absorb the

impact and vibration of each transmission part, and bring It is a lubrication system that removes the heat and

wear debris generated by friction on the surface of each transmission part, improves the

bearing capacity and

impact resistance of each transmission part, and improves the transmission efficiency of the transmission parts. The potential energy conversion electric

energy system is equipped with generators, shafts, and shaft wheels. ,

flywheel, heat exchange tube and starting wheel are a kind of system in the start-up phase. The generator is driven by the motor to run and the actual output power is supplied to the

electrical equipment outside the system. After the system enters the program replacement and normal operation, the generator It can not only undertake the force falling potential energy and inertial potential energy transmitted by the

momentum wheel group and convert them into electrical energy, but also supply the actual electrical energy output by the generator in groups, that is, a group of electrical energy is fed back to the system in a circular feedback manner.

Microcomputer controller for running work, left

pressure sensor, right pressure sensor, speed sensor,

oil temperature sensor,

water temperature sensor,

cooling water temperature sensor, cooling

water pressure sensor,

oil pressure sensor, oil

level sensor,

water heater,

motor control, Centrifugal pumps, cooling pumps, cooling electric fans, lubricating oil pumps, chain oil timing valves, shaft oil timing valves, oil filters and oil-electric fans maintain the running system for

continuous operation Another group of surplus electric energy can be used to supply power to the outside of the system supply system; the operating principle of the

operating system of the present invention is divided into start-up stage,

There are three stages of program replacement and normal operation; in the start-up stage, start-up power is provided from the outside of the system to all electrical components in the system except for the generator to make each electrical component, including the centrifugal pump and the starter motor, run in the early stage, and the starter motor receives start-up power from outside the system Carry out the operation and drive the generator in the system to run through the starting wheel and the starting wheel, including the shaft wheel, and implement the operation with each momentum wheel in the drive system and the O-shaped box chain ring in the drive system, including each load-bearing The box runs continuously at a speed of 1cm / s so that each load-bearing box placed on the O-shaped box chain ring can randomly load the water output by the centrifugal pump in the state of fluid and power advancement when passing through the water outlet. The pump receives the start-up power provided by the system and operates. It always lifts the water in the water tank upwards and transports it to a load-bearing box at the top of the load-bearing

box set that is aligned with the water outlet. The centrifugal pump operates every 1s. The amount of water delivered to a load-bearing box that passes through the water outlet in a state of fluid and power advancement within a period of time is consistent with the water-

carrying capacity of a load-bearing box that passes through the water outlet every 1s, so that each load-bearing box in the system is The amount of water in a condensed state that can be loaded to a sufficient value, when the accumulated gravity of the water in a condensed state that is hoarded in the load-bearing box group has reached the range of the set value, it will form in the system that can be operated by the starter motor. The potential energy generated in the process drives the system to run, and it can also be accumulated in the load-bearing box group in a condensed state. The gravity moves vertically downward at a speed of 1cm / s according to the natural law that the force is always vertically downward. The power drop potential energy and the inertial potential energy produced in the motion process drive the two kinds of driving potential energy of the system to implement operation. When choosing one of the two, the latter is selected, and the latter is the fundamental adjustment system operation program to make the present invention enter Program replacement stage; program replacement and normal operation can

cut off the starting power provided by the system from the outside to the system. When the system does not receive any

external energy supply and no longer consumes any

external energy, it is stored in the load-bearing box group. The aggregated gravity of the water in the condensed state can always work together with the momentum wheel group and move vertically downward at a speed of 1cm / s according to the natural law that the force always moves vertically downward, and then the generator will move at a speed of 1cm / s The force falling potential energy and inertial potential energy generated during the vertical downward movement are converted into electric energy, which enables the operation system of the present invention to operate. The feed-back electric energy fed back to each electrical component in the system except the start-up motor in the form of circular feedback, each electrical component in the system except the start-up motor receives a group of feed-back electric energy in the actual output electric energy of the generator, and then the electric energy is transferred to It only stops for one

microsecond during the connection process, and it never stops working for an instant. It is always running continuously. After the centrifugal pump in the system receives a group of feedback power from the actual output of the generator, it only stops for one

microsecond during the power transfer process. The work has never stopped in an instant, and the water in the tank can be lifted upwards and transported to a load-bearing box at the top of the load-bearing box set that is opposite to the water outlet with fluid and power advancement, so that the water is stored in the load-bearing box set The aggregated gravity of water in a condensed state can always move vertically downward at a speed of 1cm / s according to the natural law that the force always moves vertically downward, and can generate force during the process of moving vertically downward at a speed of 1cm / s The falling potential energy and inertial potential energy can also establish a force point on the torx teeth of the torx left wheel and the torx right wheel, and from this point of force, the force drop potential energy and inertial potential energy can be converted into torque and speed to drive the O-shape in the system. The box chain ring includes each load-bearing box running at a speed of 1cm / s for continuous circulation, so that each load-bearing box placed on the O-shaped box chain ring passes through the centrifugal pump during the continuous cycle operation at a speed of 1cm / s The water outlet can be randomly loaded with the water output by the centrifugal pump in the state of fluid and power advancement and stored in each load-bearing box. The

water delivery volume in the load-bearing box is the same as the water-

carrying capacity of a load-bearing box passing through the water outlet every 1s, so that the centrifugal pump can always run to the bottom of the load-bearing box group with fluid and dynamic momentum. When the box body is restrained by the arcs of the lower left cooperating wheel and the lower right cooperating wheel, the mouth of the box is gradually downwards, so that the water contained in the box can be discharged to the sink in the same

time gap in the same time interval when the water in the box falls to the sink in a

waterfall style according to its own gravity. The water with the same flow rate and the same volume and the same gravity is compensated in equal amounts in a load-bearing box at the top of the load-bearing box group and the water outlet, so that the accumulated gravity of the water in the condensed state hoarded in the load-bearing box group 1 load-bearing box carries water, the other 1 load-bearing box unloads water, and the 1 load-bearing box carries water and the other 1 load-bearing box unloads water. During the alternate loading and unloading operation process, it always remains unchanged, and is hoarded in the load-bearing box group in a condensed state The aggregated gravity value of the water in the state is always kept constant, so that the force falling potential energy and inertial potential energy that can drive the generator including the entire system to operate in the system always exist, and the accumulation of water in a condensed state that is hoarded in the load-bearing box group The gravity value is always kept constant so that the accumulated gravity of the water accumulated in the condensed state in the load-bearing box group can always move vertically downward at a speed of 1cm / s according to the natural law of force and always move vertically downward. In the process of moving vertically downward at a speed of 1cm / s, a strong point can be established on the torx teeth of the torx left wheel and torx right wheel. The force falling potential energy and inertial potential energy generated during the vertical downward movement of the water accumulated in the load-bearing box group in a condensed state at a speed of 1cm / s are converted into torque and rotational speed, and are determined by plum blossoms. The torx teeth of the left wheel and the torx right wheel will force the falling potential energy and inertial potential energy or the converted torque and rotating speed to the same axle of the torx left wheel and torx right wheel, that is, the torx teeth and the axle of the torx left wheel and torx right wheel will The accumulated gravity of the

condensed water stored in the load-bearing box group changes from the upward and downward direction of work to the direction of work along the horizontal plane from the

quincunx teeth to the axle, and then the same axle of the

quincunx left wheel and the

quincunx right wheel uses the same With the center of the circle as the fulcrum, the force will drop the potential energy and inertial potential energy or the converted torque and rotational speed to do work on the gear teeth of the

gear wheel on the same wheel shaft, and then the force will drop the potential energy and inertial potential energy or The converted torque and rotational speed do work to each of the lower potential wheels, and each of the lower potential wheels follows the meshing sequence to be able to undertake the force drop potential energy and inertial potential energy or the converted torque transmitted by the previous potential wheel And the rotation speed continues downward in the form of the work done by the next momentum wheel, so that each momentum wheel in the potential

energy transfer system can always accumulate the water that is in a condensed state in the load-bearing box group at a rate of 1cm / The force falling potential energy and inertial potential energy or the converted torque and rotational speed generated during the vertical downward movement at the speed of s are transmitted to the generator shaft, so that the generator can always obtain the force falling potential energy and inertial potential

energy matching the rated power Or the converted torque and speed are converted into electrical energy, and then a group of electrical energy in the actual output electrical energy is fed back to the electrical components in the system in a circular feedback manner to maintain the system for

continuous operation. It can also supply another group of surplus electric energy in the actual output electric energy to the outside of the system; after the present invention enters normal operation, it is stored in the load-bearing box without any external

energy supply and no longer consumes any external energy. The aggregate gravity of the water in the condensed state in the box group can always work together with the momentum wheel group and move vertically downward at a speed of 1cm / s according to the natural law that the force always moves vertically downward, and then the generator will move it vertically downward at a speed of 1cm / s The force falling potential energy and inertial potential energy generated during the vertical downward movement at the speed of s per hour are converted into electric energy, which enables the

operating system of the present invention to operate. A group of electric energy is fed back to all electrical components in the system except the motor to maintain the

continuous operation of the system in a circular feedback manner, and another group of surplus electric energy in the actual output electric energy can be sent to the substation room outside the system and other electrical appliances outside the power plant The equipment is powered, and the energy that enables the operation of the existing thermal power plant depends on the carbon material swept in from the outside of the power plant to

burn in the boiler to generate potential energy, which drives the generator to run through the transmission system, and then the generator

Potential energy is converted into electric energy, and the present invention has completely overcome the problem that the existing thermal power plants rely on the operation of carbon substances swept in from outside the power plant to

burn in the boiler to generate potential energy and drive the generator through the transmission system. After running, the generator will convert the potential energy into electrical energy. It will exhaust the earth's only energy resources within a few hundred years, leaving future generations without energy resources and polluting the environment.

Login to View More

Login to View More  Login to View More

Login to View More