Rotary blade machine

A rotary vane, rotary vane technology, applied in rotary piston machines, rotary piston engines, rotary or swing piston engines, etc., can solve problems such as reducing compression ratio/expansion ratio, reducing mechanical efficiency, and large mechanical energy consumption. , to avoid friction and gap leakage, improve energy conversion efficiency, and reduce mechanical energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

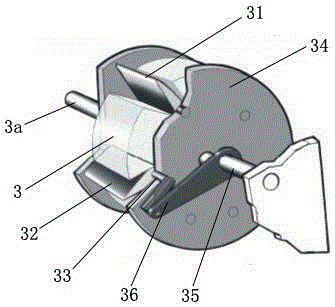

[0035] Such as Figure 4 As shown, the present invention includes a stator 1 and a rotary vane rotor 4, the rotary vane rotor 4 axis deviates from the axial center of the stator inner cylinder and is installed in the stator inner cylinder, and the rotary vane rotor 4 includes a rotor body 41, rotating blades 42 and regulating block 43;

[0036] Such as Figure 5 with Image 6 As shown, the circumferential surface of the rotor body 41 is provided with evenly distributed blade slots 41a in the axial direction, and the two sides corresponding to the bottom ends of the blade slots 41a are provided with adjusting block grooves 41b in the radial direction;

[0037] Such as Figure 7 with Figure 8 As shown, arc-shaped notches 42c are formed on both sides of the bottom end of the rotating blade 42, and the center of the arc-shaped notch 42c is provided with a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com