A kind of asphalt pavement hot-in-place recycling machine for recycling asphalt smoke and dust

A technology of asphalt pavement and recycling machine, which is applied in the direction of roads, roads, road repairs, etc. It can solve the problems of energy waste, fugitive emission of waste asphalt smoke, and environmental pollution, so as to save energy, change the problem of unorganized emission, and improve competition. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

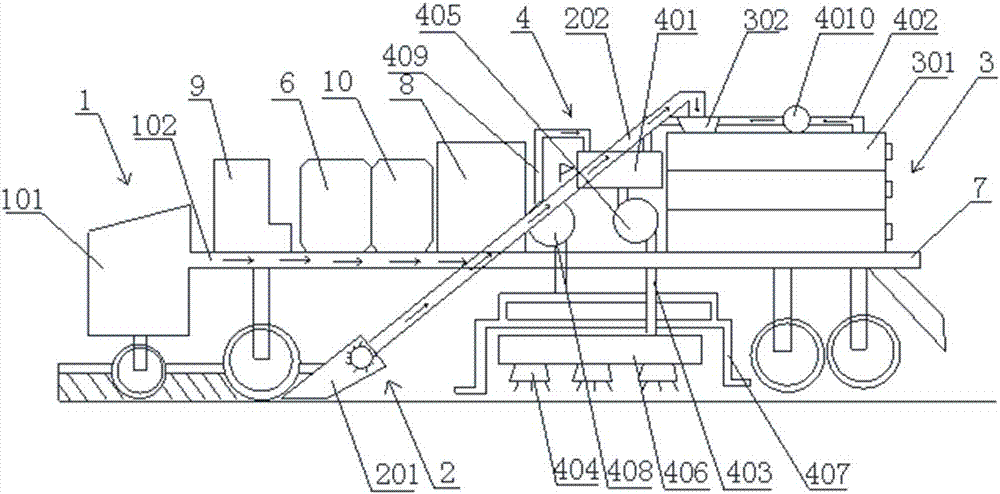

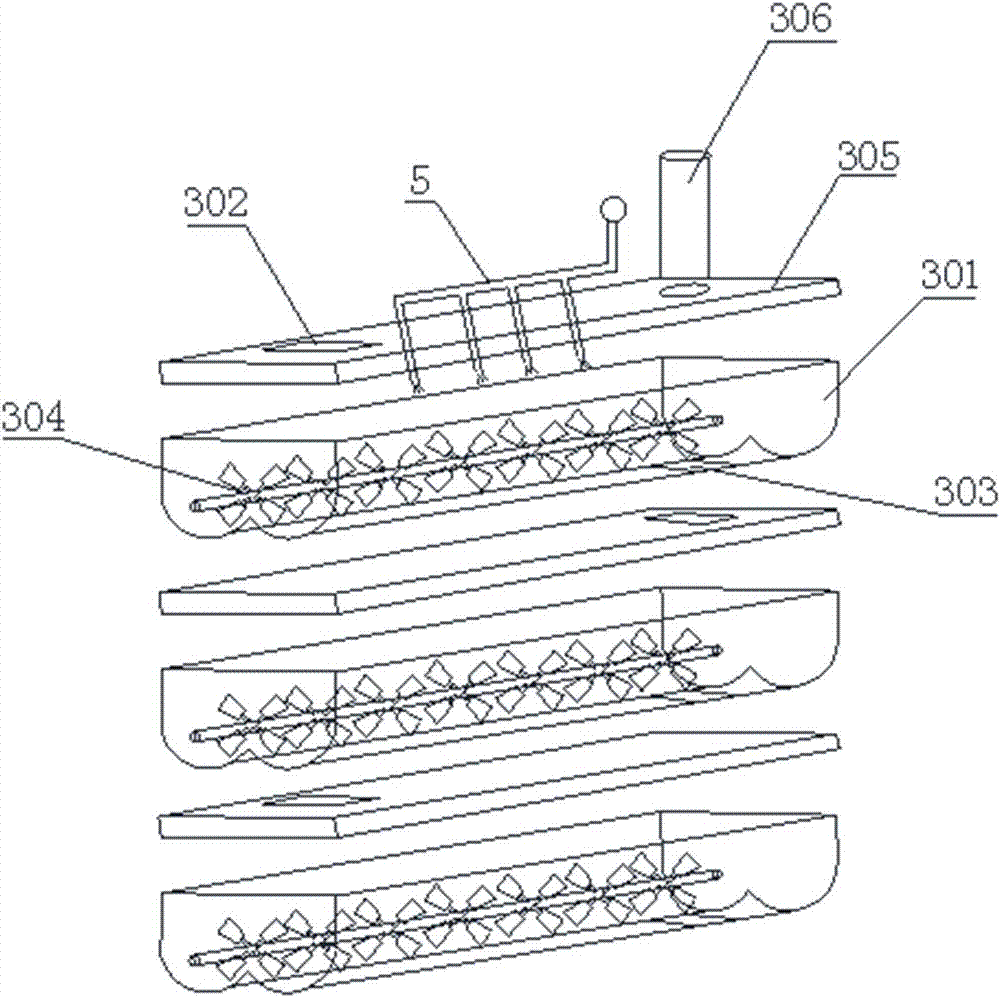

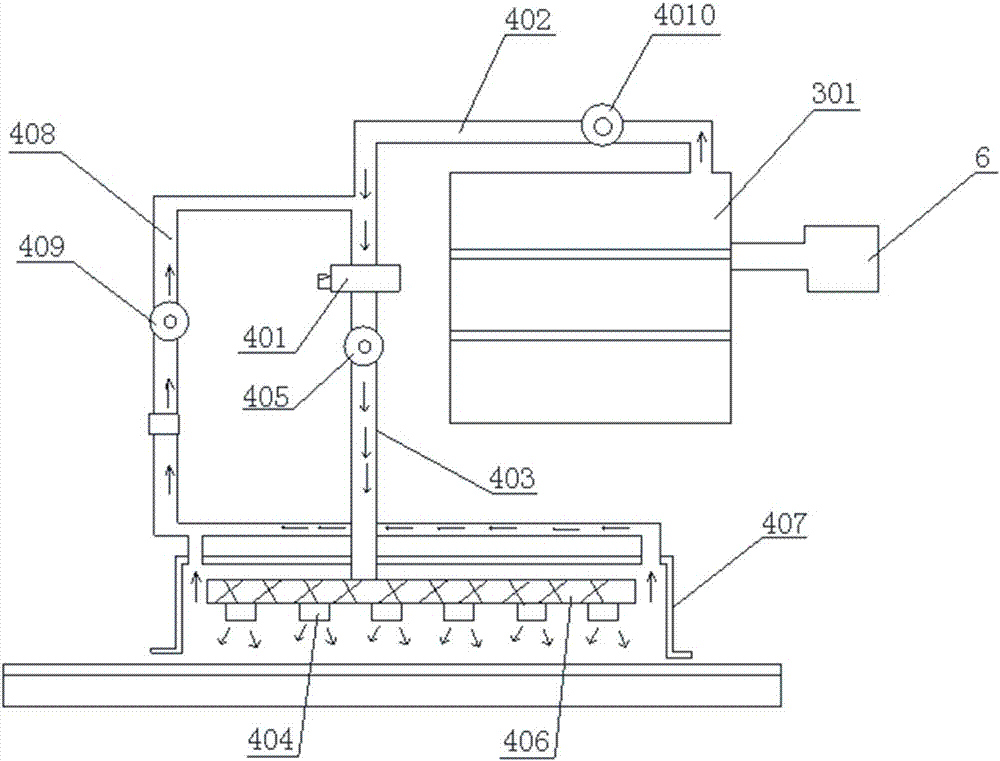

[0017] With reference to the accompanying drawings, an asphalt pavement thermal in-situ regeneration machine for recycling asphalt fumes includes a new material adding device 1 , a recycled material collecting device 2 , a layered heating device for recycled materials 3 and a recycling device 4 for regenerated waste smoke and dust. The new material adding device 1 is used to provide fresh asphalt material for the reclaimed material layered heating device 3 , and the reclaimed material collecting device 2 is used to provide the reclaimed material layered heating device 3 with pavement reclaimed material. The recycled material collection device 2 includes a receiving bucket 201 and an inclined feeding conveyor belt 202. The receiving bucket 201 is arranged at the bottom of the inclined feeding conveyor belt 202, and the top of the inclined feeding conveyor belt 202 is connected to the layered heating of recycled materials. device 3. Described new material adding device 1 compris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com