A kind of pulping equipment with automatic adjustment of rotor height

An automatic adjustment and rotor technology, applied in the direction of raw material separation, can solve the problems of high energy consumption of equipment, uneven pulping, low pulping efficiency, etc., and achieve the effect of agitating the fluid in a large area and improving the crushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

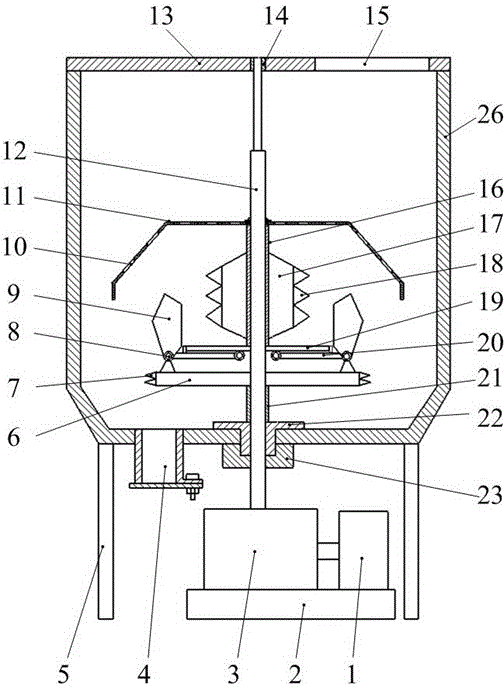

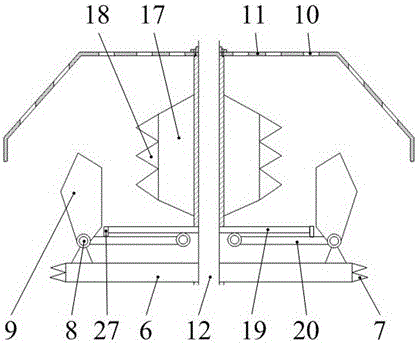

[0019] Such as figure 1 As shown, a rotor height automatic adjustment type pulping equipment mainly includes a power drive device, a pulping device, a height self-adjusting device and a slurry generating device.

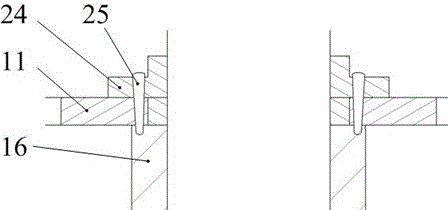

[0020] The power drive device is mainly composed of a motor 1, a reducer 3 and a main shaft 12, the motor 1, the reducer 3 and the main shaft 12 are connected in sequence, the motor 1 and the reducer 3 are installed on the base 2, the main shaft 12 is a stepped shaft and its upper end passes through the upper The sleeve 14 is installed on the cylinder cover 13 , and the lower end is installed on the material cylinder 26 through the sealing sleeve 22 and the lower fixing sleeve 23 .

[0021] The slurry generating device is mainly composed of a material cylinder 26 and a cylinder cover 13. The material cylinder 26 is installed on four circumferentially evenly distributed pillars 5, the lower end of the material cylinder 26 is provided with a slurry outlet 4, and the cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com