Radial guide wheel type banana straw crushing and returning machine

The technology of banana straw and guide wheel mechanism is applied in the field of agricultural machinery, which can solve the problems of increasing pests and diseases in banana fields, deterioration and rot of banana straw, affecting the passage of field roads, etc., and achieves the effects of improving the crushing effect, good crushing effect and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

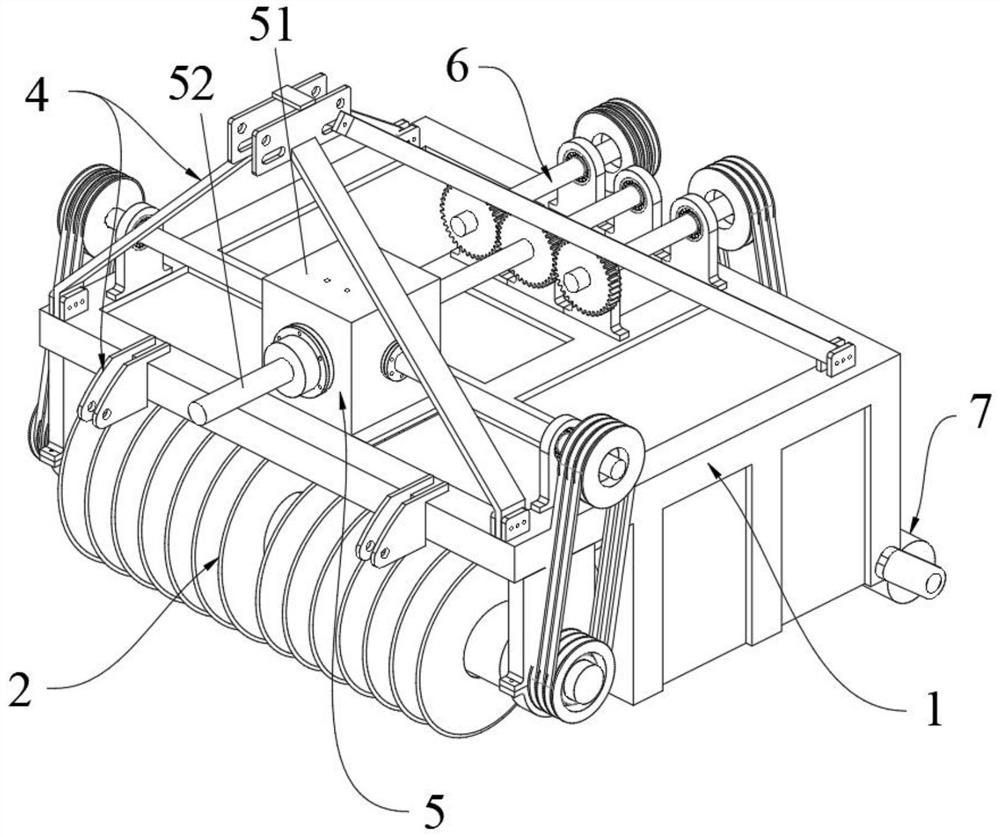

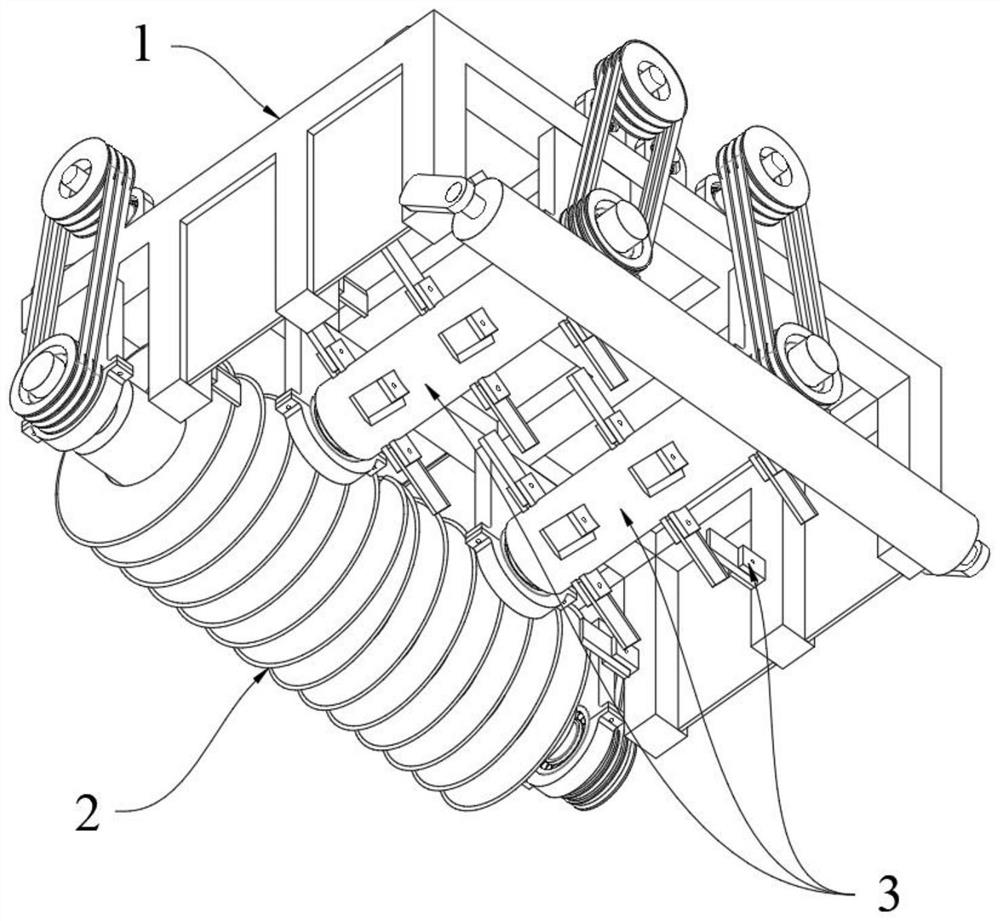

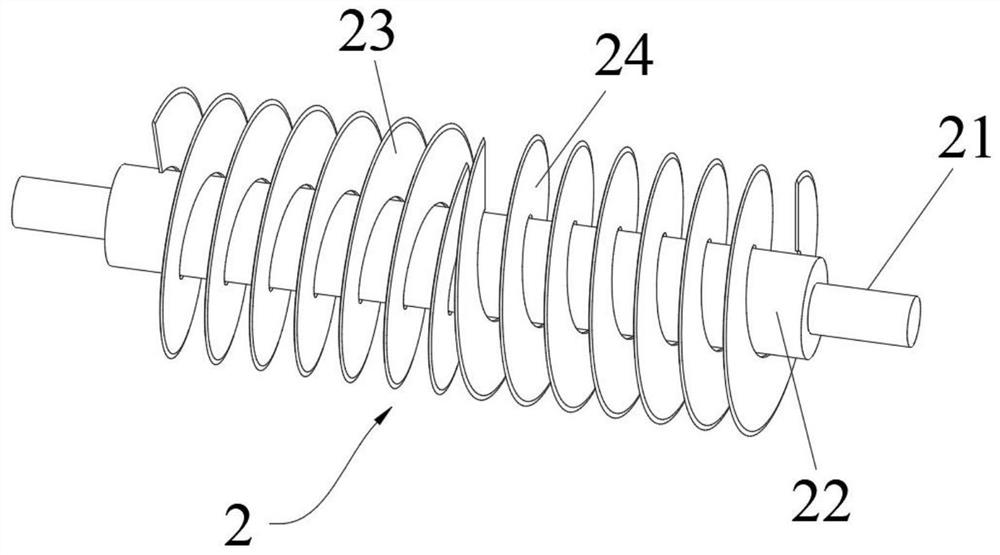

[0028] Such as Figure 1 to Figure 8 As shown, this embodiment provides a radial guide wheel type banana stalk crushing and returning machine, which is installed on the rear side of the towing device (such as a wheeled tractor); includes a frame 1; the bottom of the frame 1 near the front side A guide wheel mechanism 2 is installed, and a radial crushing mechanism 3 is installed near the bottom of the rear side; the guide wheel mechanism 2 is used to gather the banana stalks in the middle, and put the length direction of the banana stalks in the general front-rear direction; The radial crushing mechanism 3 is used for cutting and crushing the banana stalks in the radial direction.

[0029] In the radial guide wheel type banana straw crushing and returning machine of this embodiment, the frame 1 includes a support 11 and a vertical frame 12; the support 11 is a horizontal frame, which is a frame structure composed of a plurality of beams, and at least includes The left side cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com