Preparation method of fabric with skin care effect

A skin care and fabric technology, applied in dyeing, fabric surface trimming, weaving, etc., can solve problems such as increasing humidity, improve production efficiency, increase friction coefficient, and improve cohesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a fabric with skin care effect, comprising the steps of:

[0037] 1), dyeing:

[0038] The milk protein composite fiber and wool fiber are dyed separately, and the water used for dyeing is soft water. The dye used for dyeing is selected from the environmentally friendly imported wool reactive dye Lanersol Red 6G. The dyeing temperature is controlled at 70 ° C, kept for 55 minutes, and 2 % low-temperature dyeing accelerator to ensure uniform coloring and color fastness;

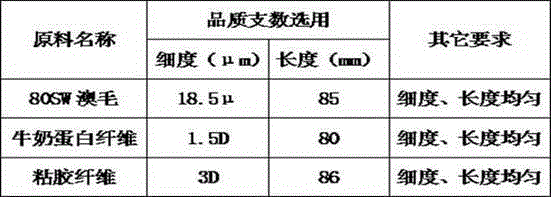

[0039] 2), mixed strips:

[0040] The dyed milk protein fiber strips are pad-rolled with a water-based polyurethane solution with a viscosity of ≤3000cP, the water-based polyurethane solution contains 10% hydrophilic submicron SiOx particles, steamed, and the surface of the milk protein fiber is coated with a A layer of uneven polyurethane film;

[0041] Then comb and mix with wool and viscose fiber according to the ordinary mixing process, and add 0.3% and crude oil;

[0042]...

Embodiment 2

[0056] A method for preparing a fabric with skin care effect, characterized in that it comprises the steps of:

[0057] 1), dyeing:

[0058] The milk protein composite fiber and wool fiber are dyed separately, and the water used for dyeing is soft water. The dye used for dyeing is selected from the environmentally friendly imported wool reactive dye yellow 4G. The dyeing temperature is controlled at 80°C, kept warm for 60 minutes, and 5% low temperature is added. Accelerator to ensure uniform coloring and color fastness;

[0059] 2), mixed strips:

[0060] The dyed milk protein fiber strips are pad-rolled with a water-based polyurethane solution with a viscosity of ≤3000cP, which contains 20% hydrophilic submicron-sized SiOx particles, and steamed. At this time, the surface of the milk protein fiber is coated with a A layer of uneven polyurethane film;

[0061] Then comb and mix with wool and viscose fiber according to the ordinary mixing process, add 0.5% and crude oil;

...

Embodiment 3

[0076] A method for preparing a fabric with skin care effect, characterized in that it comprises the steps of:

[0077] 1), dyeing:

[0078] The milk protein composite fiber and wool fiber are dyed separately, and the water used for dyeing is soft water. The dye used for dyeing is selected from environmentally friendly imported reactive dye black CE for wool. The dyeing temperature is controlled at 75 ° C, kept for 58 minutes, and 4% of low temperature is added. Accelerator to ensure uniform coloring and color fastness;

[0079] 2), mixed strips:

[0080] The dyed milk protein fiber strips are pad-rolled with a water-based polyurethane solution with a viscosity of ≤3000cP. The water-based polyurethane solution contains 15% hydrophilic submicron-sized SiOx particles and is steamed. At this time, the surface of the milk protein fiber is coated with a A layer of uneven polyurethane film;

[0081] Then comb and mix with wool and viscose fiber according to the ordinary mixing pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com