Gas inflowing and cooling device for MOCVD equipment

A cooling device and equipment technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of complex structure of air intake device, affecting product quality, disturbing parasitic particles, etc., to ensure the quality of film growth , Improve the film growth rate and inhibit the effect of parasitic particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

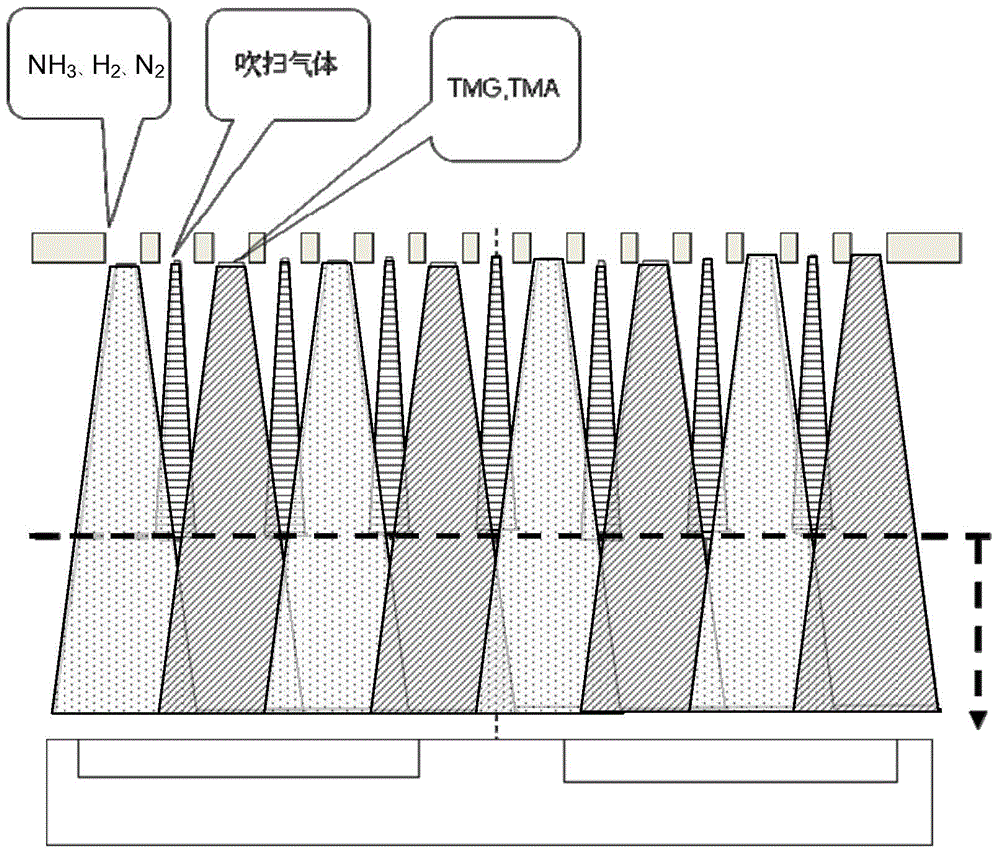

[0050] Such as Figure 4 As shown, the air inlet device provided by the present invention is a shower head 800, which is arranged on the top of the MOCVD (metal organic chemical vapor deposition) equipment reaction chamber 900, through the first air inlet conduit 810 provided, the second inlet The gas conduit 820 and the first air inlet 830 respectively deliver the organometallic gas and the hydride gas into the reaction chamber 900, and the carrier gas that carries them to the surface of the substrate 920 for film deposition reaction, and at the same time passes through the first The carrier gas delivered by the gas inlet 830 separates the organometallic gas and the hydride gas from each other, so as to prevent the premature reaction of the just injected organometallic gas and hydride gas from generating parasitic gas near the gas inlet on the bottom surface of the shower head 800. particles.

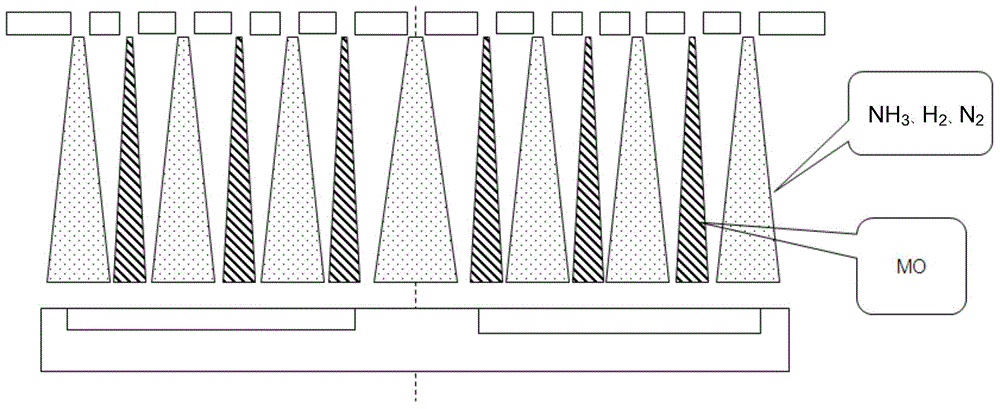

[0051] Such as Figure 5 As shown, a group of second air inlets 840 is also prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com