A kind of antibacterial coating masterbatch, antibacterial coating woven bag and production method thereof

A production method and technology of woven bags, which are applied in the field of antibacterial coating masterbatch and woven bags, can solve the problems that the product storage and sales process cannot be fully utilized, stored grains and grains are easy to deteriorate, and do not have antibacterial functions, etc., to achieve superior barrier Functional, high antibacterial rate, excellent effect of precipitation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

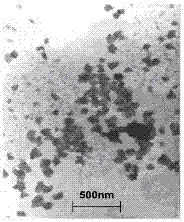

[0040] Embodiment 1, a kind of antibacterial coating film masterbatch, comprise the raw material of following weight portion: coating film grade polyethylene pellet

[0041] 56 parts; 33 parts of nano-silver antibacterial agent; 3 parts of oxidized polyethylene wax; 5 parts of auxiliary agent;

[0042] The auxiliary agent is light stabilizer, antioxidant and coupling agent, and the mass ratio is 1:3:2.

[0043] The preparation method of this antibacterial coating masterbatch:

[0044] (1) Mix the above-mentioned various raw materials in a mixer at high speed for 5 minutes;

[0045] (2) Import the raw material mixture obtained in step 1 into the twin-screw granulator through vacuum suction;

[0046] (3) Melt extrusion at 210-270°C, water cooling, air drying, material cutting, screening, and packaging to obtain an antibacterial coating film masterbatch.

[0047] The above coating masterbatch is used to produce antibacterial coating woven bags, and the coating materials of ant...

Embodiment 2

[0052] Embodiment 2, a kind of antibacterial coating film masterbatch, comprise the raw material of following weight portion: The company produces polypropylene powder

[0053] 60 parts of raw material; 30 parts of nano-silver antibacterial agent; 4 parts of oxidized polyethylene wax; 6 parts of auxiliary agent;

[0054] The auxiliary agent is light stabilizer, antioxidant and coupling agent, and the mass ratio is 1:3:2.

[0055] The preparation method of this antibacterial coating masterbatch:

[0056] (1) Mix the above-mentioned various raw materials in a mixer at high speed for 5 minutes;

[0057] (2) Import the raw material mixture obtained in step 1 into the twin-screw granulator through vacuum suction;

[0058] (3) Melt extrusion at 210-270°C, water cooling, air drying, material cutting, screening, and packaging into finished products.

[0059] The above coating masterbatch is used to produce antibacterial coating woven bags, and the coating materials of antibacterial...

Embodiment 3

[0064] Embodiment 3, a kind of antibacterial coating film masterbatch, comprise the raw material of following weight part: 64 parts of coating film grade polypropylenes; 27 parts of nano-silver series antibacterial agents; 5 parts of oxidized polyethylene waxes; 7 parts of auxiliary agents;

[0065] The auxiliary agent is light stabilizer, antioxidant and coupling agent, and the mass ratio is 1:3:2.

[0066] The preparation method of this antibacterial coating masterbatch:

[0067] (1) Mix the above-mentioned various raw materials in a mixer at high speed for 5 minutes;

[0068] (2) Import the raw material mixture obtained in step 1 into the twin-screw granulator through vacuum suction;

[0069] (3) Melt extrusion at 210-270°C, water cooling, air drying, material cutting, screening, and packaging into finished products.

[0070] The above coating masterbatch is used to produce antibacterial coating woven bags, and the coating materials of antibacterial coating woven bags inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

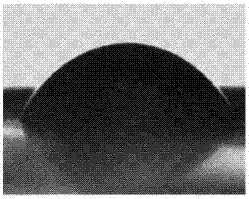

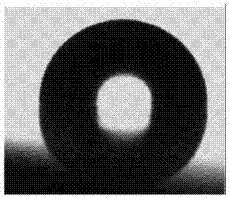

| contact angle | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com