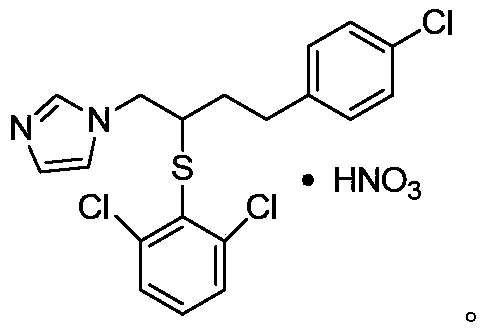

A kind of method of industrialized synthesis butoconazole nitrate intermediate

A kind of technology of butconazole nitrate and intermediate, applied in the field of synthesis technology of butoconazole nitrate, can solve the problems such as product yield and purity that cannot satisfy industrialized production, high cost, complicated butconazole nitrate production process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

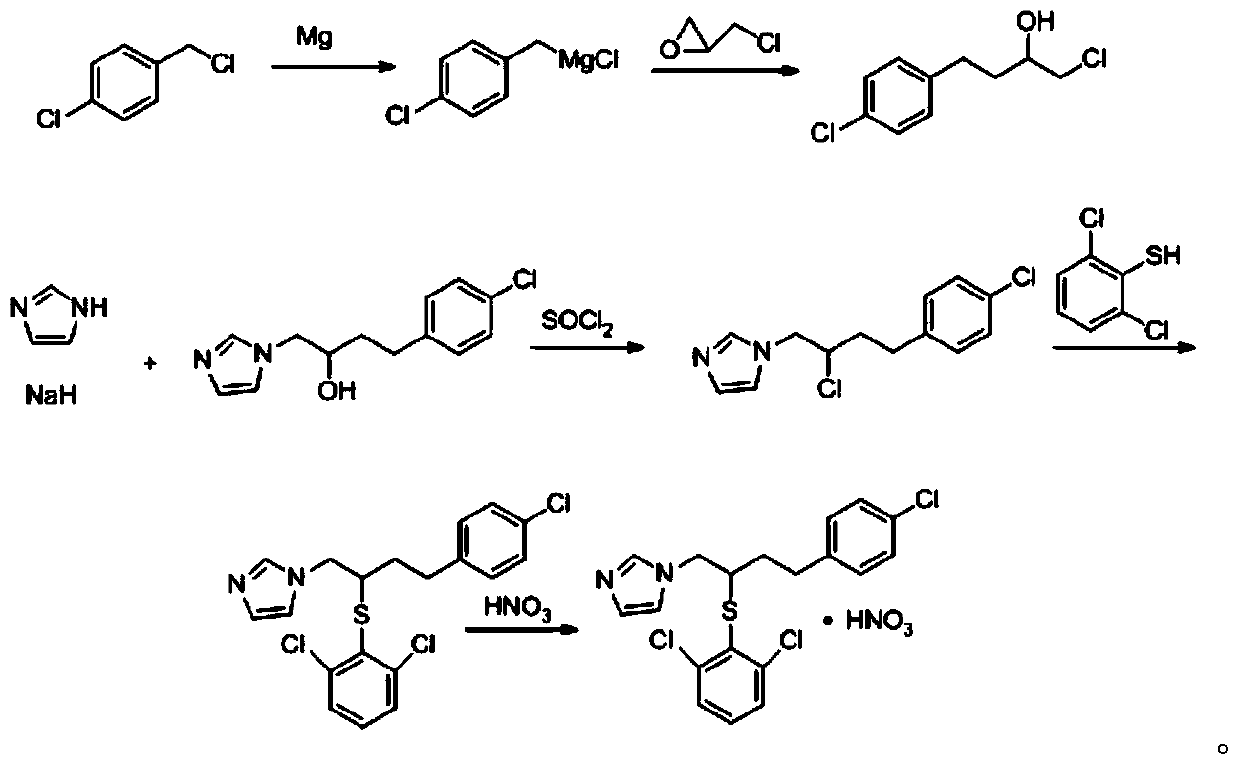

Method used

Image

Examples

Embodiment 1

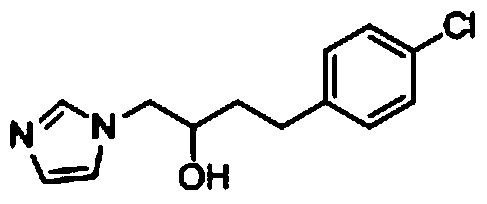

[0049] 1-(2-Hydroxy-4-(4-chlorophenyl)butyl)-1hydro-imidazole was prepared as follows:

[0050] (1) Get 7kg concentration of 20% sodium hydride DMF solution, under ice bath condition, add dropwise 7kg concentration of 20% imidazole DMF solution while stirring at a speed of 2ml / s, and stir and react at 60°C for 60min; After cooling in an ice-salt bath, slowly add 5 kg of 1-chloro-4-(4-chlorophenyl)-2-butanol, stir and react at 60°C for 120 minutes, and cool in an ice-salt bath to obtain a reaction solution;

[0051] (2) Get the reaction solution gained in step (1), add 25% n-hexane accounting for the weight of the reaction solution, stir at a speed of 3 rpm for 15 min, then add ice water accounting for 350% of the weight of the reaction solution, Stir at a speed of 3 revolutions per second until the precipitation stops and then filter, wash the filter cake once with water accounting for 1 / 3 times the weight of the filter cake, and dry it by centrifugation at a speed of 2825 r / m...

Embodiment 2

[0054] Compared with Example 1, the difference is only that the step (1) is specifically:

[0055] (1) Take 5 kg of a 10% sodium hydride DMF solution, add 5 kg of a 10% imidazole DMF solution dropwise while stirring at a speed of 1 ml / s under ice bath conditions, and stir and react at 58° C. for 55 min; After cooling in an ice-salt bath, slowly add 3kg of 1-chloro-4-(4-chlorophenyl)-2-butanol, stir and react at 58°C for 115min, and cool in an ice-salt bath to obtain a reaction solution.

[0056] After testing, the yield of the product of this example was 70.7%. The target product and impurity content were detected by HPLC and standard substances. After testing, the content of the target product 1-(2-hydroxyl-4-(4-chlorophenyl)butyl)-1 hydrogen-imidazole is 98.78%, 1-(1-chloro-4-(4-chlorophenyl ) butane-2-yl)-1 hydrogen-imidazole content is 0.87%, 4-(4-(1 hydrogen-imidazol-1-yl) phenyl)-1-chloro-2-butanol content is 0.09% %.

Embodiment 3

[0058] Compared with Example 1, the difference is only that the step (1) is specifically:

[0059] (1) Get 9kg concentration of 30% sodium hydride DMF solution, under ice bath conditions, add dropwise 9kg concentration of 30% imidazole DMF solution while stirring at a speed of 3ml / s, and stir and react at 62°C for 65min; After cooling in an ice-salt bath, slowly add 7kg of 1-chloro-4-(4-chlorophenyl)-2-butanol, stir and react at 62°C for 125min, and cool in an ice-salt bath to obtain a reaction solution.

[0060] After testing, the yield of the product of this example was 70.3%. The target product and impurity content were detected by HPLC and standard substances. After detection, the content of the target product 1-(2-hydroxyl-4-(4-chlorophenyl)butyl)-1 hydrogen-imidazole is 99.01%, 1-(1-chloro-4-(4-chlorophenyl )butane-2-yl)-1hydrogen-imidazole content is 0.63%, 4-(4-(1hydrogen-imidazol-1-yl)phenyl)-1-chloro-2-butanol content is 0.07% %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com