FBC (fluidized bed combustion) ash containing cement and preparation method thereof

A technology of sulfur-fixing ash and cement, applied in cement production and other directions, can solve problems such as pollution, increase the use of sulfur-fixing ash and cement production cost, and achieve the effects of reducing environmental pollution, reducing production costs, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

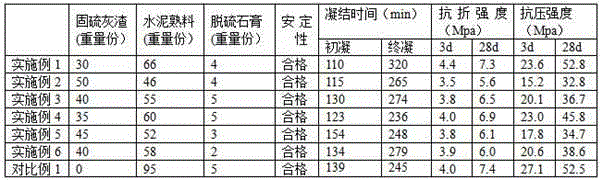

Examples

Embodiment 1

[0024] A sulfur-fixing ash cement is prepared from the following raw materials in parts by weight: 30 parts of sulfur-fixing ash, 66 parts of 52.5 ordinary Portland cement clinker, and 4 parts of desulfurized gypsum.

[0025] The production method of the sulfur-fixed ash used in the sulfur-fixed ash cement comprises the following steps:

[0026] Step 1, 50 parts of calcium oxide, 10 parts of zinc slag, 2 parts of copper slag, 4 parts of activator calcium fluoride, stabilizer Al 2 o 3 1 part, 1 part of the activator calcium sulfoaluminate is added to a ball mill and mixed, and the powder of 0.1-5mm (1.5mm accounts for 10%) powder is obtained by ball milling. Product sulfur fixative.

[0027] Among them, CaO15wt% in zinc slag, SiO 2 20wt%, FeO5wt%, Fe 2 o 3 20wt% and ZnO5wt%; Fe in copper slag 2 o 3 20wt%, SiO 2 30wt%, CaO5wt% and Al 2 o 3 2wt%.

[0028] In step 2, the coal and the sulfur-fixing agent accounting for 10% of the weight of the coal are transported to the...

Embodiment 2

[0033] A sulfur-fixing ash cement is prepared from the following raw materials in parts by weight: 50 parts of sulfur-fixing ash, 46 parts of 52.5 ordinary Portland cement clinker, and 4 parts of desulfurized gypsum.

[0034] The production method of the sulfur-fixed ash used in the sulfur-fixed ash cement comprises the following steps:

[0035] Step 1, 55 parts of calcium oxide, 12 parts of zinc slag, 2.2 parts of copper slag, 5 parts of activator calcium fluoride, stabilizer SiO 2 2 parts, 1.1 parts of activator calcium sulfoaluminate are added into a ball mill and mixed, ball milled into a powder of 0.1-5mm (1.5mm accounts for 5%) powder, and stands for 10h, that is Product sulfur fixative.

[0036] Among them, CaO11wt% in zinc slag, SiO 2 23wt%, FeO5wt%, Fe 2 o 3 18wt% and ZnO2wt%; Fe in copper slag 2 o 3 27wt%, SiO 2 35wt%, CaO6wt%, Al 2 o 3 3wt%.

[0037] In step 2, the coal and the sulfur-fixing agent accounting for 7% of the coal-fired weight are transported ...

Embodiment 3

[0042] A sulfur-fixing ash cement is prepared from the following raw materials in parts by weight: 40 parts of sulfur-fixing ash, 55 parts of 52.5 ordinary Portland cement clinker, and 5 parts of desulfurized gypsum.

[0043] The production method of the sulfur-fixed ash used in the sulfur-fixed ash cement comprises the following steps:

[0044]Step 1, 61 parts of calcium oxide, 15 parts of zinc slag, 2.6 parts of copper slag, 5.2 parts of activator calcium fluoride, stabilizer SiO 2 1.2 parts and Al 2 o 3 1.2 parts, 1.5 parts of activator calcium sulfoaluminate are added into ball mill and mixed, ball milled into powder of 0.1~5mm (1.5mm accounts for 10%) powder, stands still for 8 hours, that is Product sulfur fixative.

[0045] Among them, CaO12wt% in zinc slag, SiO 2 21wt%, FeO6wt%, Fe 2 o 3 21wt% and ZnO3wt%; Fe in copper slag 2 o 3 30wt%, SiO 2 38wt%, CaO7wt% and Al 2 o 3 2wt%.

[0046] In step 2, the coal and the sulfur-fixing agent accounting for 8% of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com