Reversible mobile crown block stockpiling device for coal storage yard

A crane and stacking technology, which is applied to the field of reversible mobile crane stacking devices in coal yard, can solve the problems of occupying space, reducing the clearance of the maintenance platform, etc., achieving the effects of diverse functions, saving economic costs, and overcoming excessive travel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

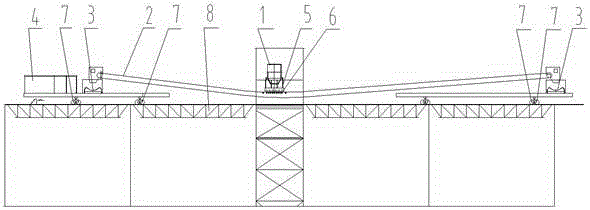

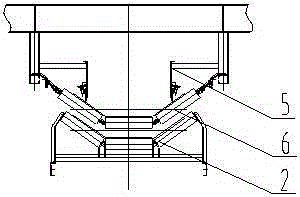

[0020] Referring to the accompanying drawings, a reversible mobile crane stockpiling device in a coal yard includes a belt conveyor 1, a mobile reversible belt conveyor 2, a suspended reversible belt feeder 3, an electrical control room 4, a hanging guide Material trough 5, hanging idler group 6, traveling drive device 7, unloading car steel structure 8, crane anchoring device 9, belt conveyor 1 is an incoming material belt conveyor, supported in the air by the steel structure, and vertically For the mobile reversible belt conveyor 2, a steel structure transfer tower is set at the transfer point, the hanging material guide trough 5 and the hanging idler roller group 6 are fixed on the transfer tower, and the reversible belt feeder 3 and the electric conveyor are suspended The control room 4 is fixed on the steel structure at both ends of the mobile reversible belt conveyor 2, and the driving device 7 is fixed under the structure at both ends of the mobile reversible belt convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com