Medicinal flame-retardant plastic packaging material and preparation process thereof

A technology of plastic packaging and preparation technology, which is applied in the field of pharmaceutical packaging materials, can solve the problems of non-conformity with technical requirements and quality requirements, and unsuitable packaging materials, etc., and achieve the effects of good environmental protection degradation characteristics, accelerated degradation speed, and good flame-retardant characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

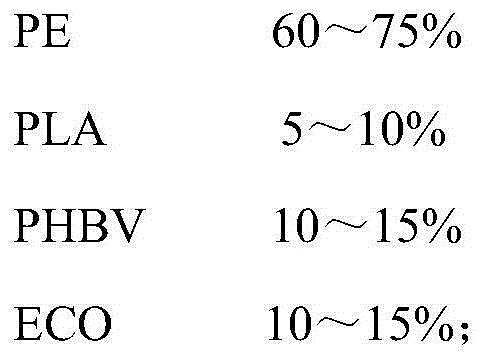

[0040] The composition of the raw material formula is shown in Table 1.

[0041] The preparation process of the medical flame-retardant plastic packaging material described in this embodiment includes the following steps:

[0042] (1) Start the air-conditioning unit: make the film blowing area of the production workshop reach Class C, and the bag making area and inner packaging area reach Class B;

[0043] (2) Disinfection of clean area: thorough disinfection according to GMP requirements;

[0044] (3) Air or nitrogen purification: After air or nitrogen is purified, it reaches Class C cleanliness standards;

[0045] (4) Mixing: Mix the formula raw materials evenly;

[0046] (5) Film blowing: control the barrel temperature to 175±3°C, the die temperature to 165±3°C, and the blow-up ratio to 2.0;

[0047] (6) Winding: Winding into film or cutting bags according to requirements, and the heat sealing temperature of cutting bags is 210±3℃.

Embodiment 2

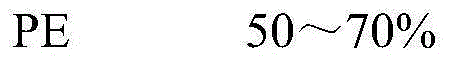

[0049] The composition of the raw material formula is shown in Table 1.

[0050] The preparation process of the pharmaceutical flame-retardant plastic packaging material in this embodiment is the same as that in Example 1, except that in step (5), the temperature of the barrel is controlled to be 185±3°C, and the temperature of the die is 175±3°C. The inflation ratio is 3.0; the heat-sealing temperature in step (6) is 217±3°C.

Embodiment 3

[0052] The composition of the raw material formula is shown in Table 1.

[0053] The preparation process of the pharmaceutical flame-retardant plastic packaging material in this embodiment is the same as that in Example 1, except that in step (5), the temperature of the barrel is controlled to be 190±3°C and the temperature of the die is 170±3°C. The inflation ratio is 2.7; the heat sealing temperature in step (6) is 225±3°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com