A rotary flushing unblocking pig

A technology of pigging and unblocking, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as many hard dirt and easy to get stuck, and achieve the effect of saving energy consumption and avoiding trouble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the drawings:

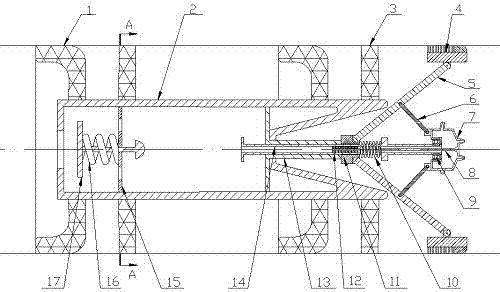

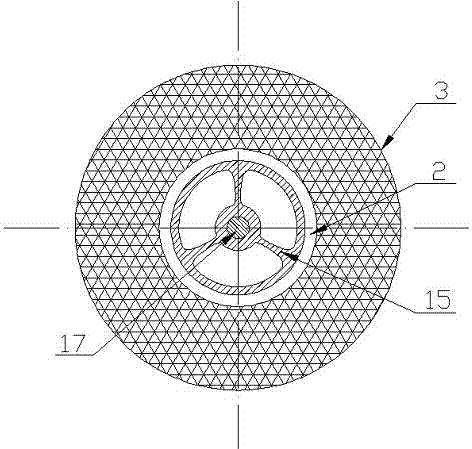

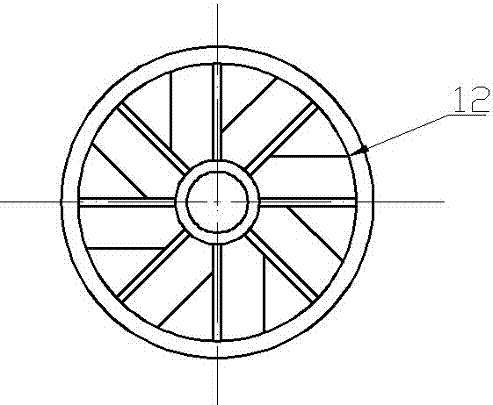

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a rotary scouring and blocking removal pig of the present invention includes a main cylinder 2, a secondary cylinder 14, a pressure control valve 17, a rotary scouring mechanism, and a scraper 3 and a cup 1 installed on the main shaft of the pig constitute. The auxiliary cylinder 14 is fixed at the front end of the main cylinder 2, the pressure control valve 17 is fixed in the inner cavity at the rear of the main cylinder 2, and the rotating flushing mechanism is installed on the auxiliary cylinder 14; the pressure control valve 17 passes The supporting plate 15 is fixed on the inner wall of the pig main cylinder 2; the supporting plate 15 is a hollow structure; there is a second spring 16 for controlling the pressure between the large end of the pressure control valve 17 and the supporting plate 15; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com