Method for recycling metal and combustibles from domestic waste incineration slag

A technology of domestic waste incineration and slag, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problem of gravity separation and recovery of high metal debris content, affecting the stripping effect of metals and debris, and the combination of crushing and screening. Unreasonable and other problems, to achieve the effect of high separation efficiency and product grade, improved eddy current separation recovery rate, and strong selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

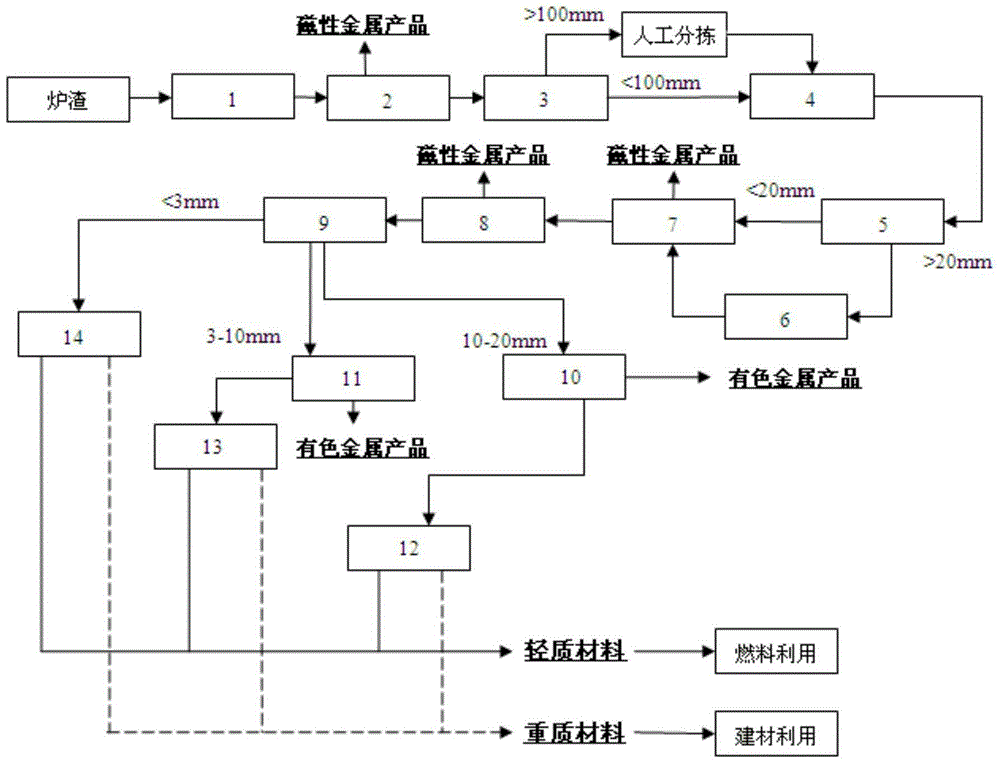

[0035] A method for recovering metals and combustibles from domestic waste incineration slag, the process is as follows figure 1 shown, including the following steps:

[0036] (1) The domestic waste incineration slag obtained after the domestic waste is incinerated in an incineration power plant is transported to the vibrating feeder 1 by a forklift from the stacking area;

[0037] (2) After the slag is fully dispersed by the vibrating feeder 1, it falls into the belt conveyor, and is transported through the first-stage magnetic separator 2 (suspended magnetic separator), and the magnetic separation intensity is controlled between 0.05T-0.2T. Sorting out large pieces of ferromagnetic metal in the slag, and the remaining slag enters the next step;

[0038] (3) After the first-stage magnetic separation, the slag is lifted by a belt and transported to the first-stage vibrating screen 3 for screening. The sieve aperture of the first-stage vibrating screen 3 is 100mm. Large piece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com