Saw blade with high stability

A technology with strong stability and saw blades, which is applied in the direction of grain processing, etc., can solve the problems of the overall structure of the saw blades to be improved, the difficulty of saw blade debugging, and uneven crushing particle size, so as to alleviate thermal deformation, improve heat dissipation, and improve The effect of smashing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

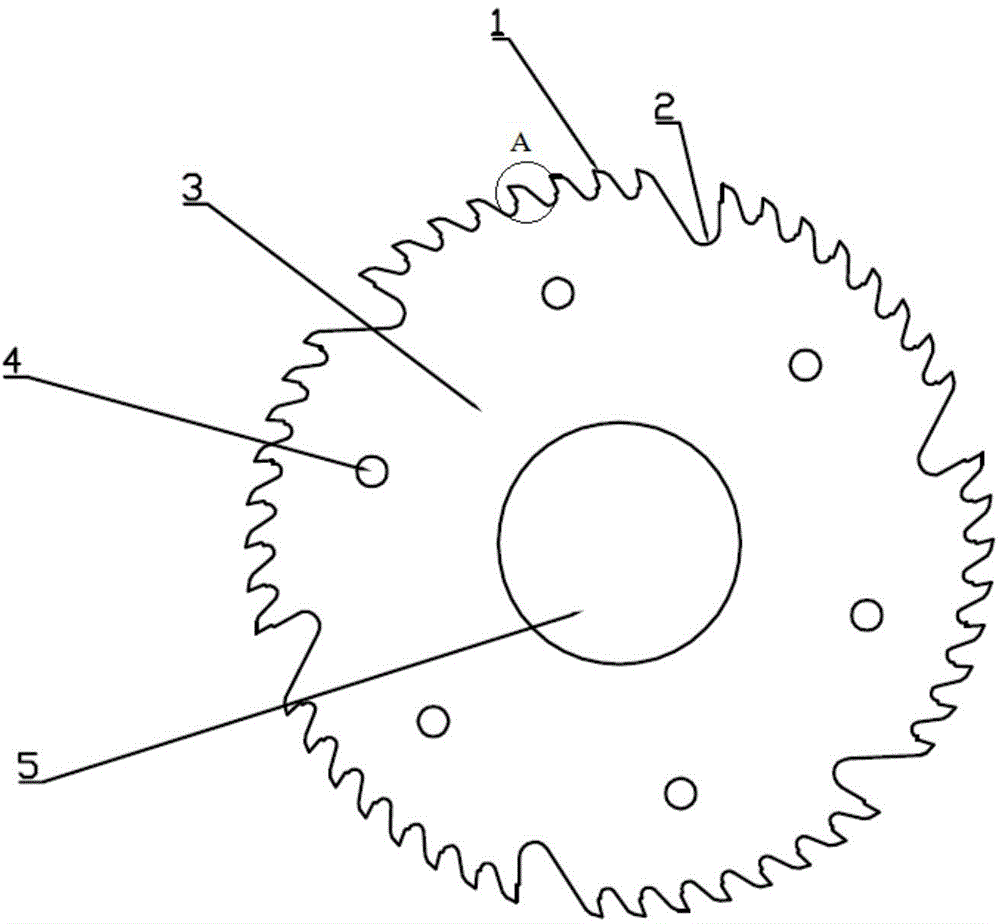

[0027] A saw blade with strong stability, including a saw blade main body 3, a cutting edge 1, a central hole 5, and also includes jump teeth 2 and cooling holes 4, wherein the saw blade main body 3 is in the shape of a disc, and the central hole 5 is located on the saw blade The geometric center of the main body 3, the cutting edge 1 is distributed on the outer circumference of the saw blade main body 3, the skip teeth 2 are evenly distributed on the outer circumference of the saw blade main body 3, the heat dissipation holes 4 are located on the saw blade main body 3 and each heat dissipation hole 4 is evenly distributed on the saw blade body 3 The main body 3 is on a circumference of a concentric circle, the diameter of the cooling hole 4 is 5% of the diameter of the saw blade main body 3 , and the diameter of the central hole 5 is 35% of the diameter of the saw blade main body 3 .

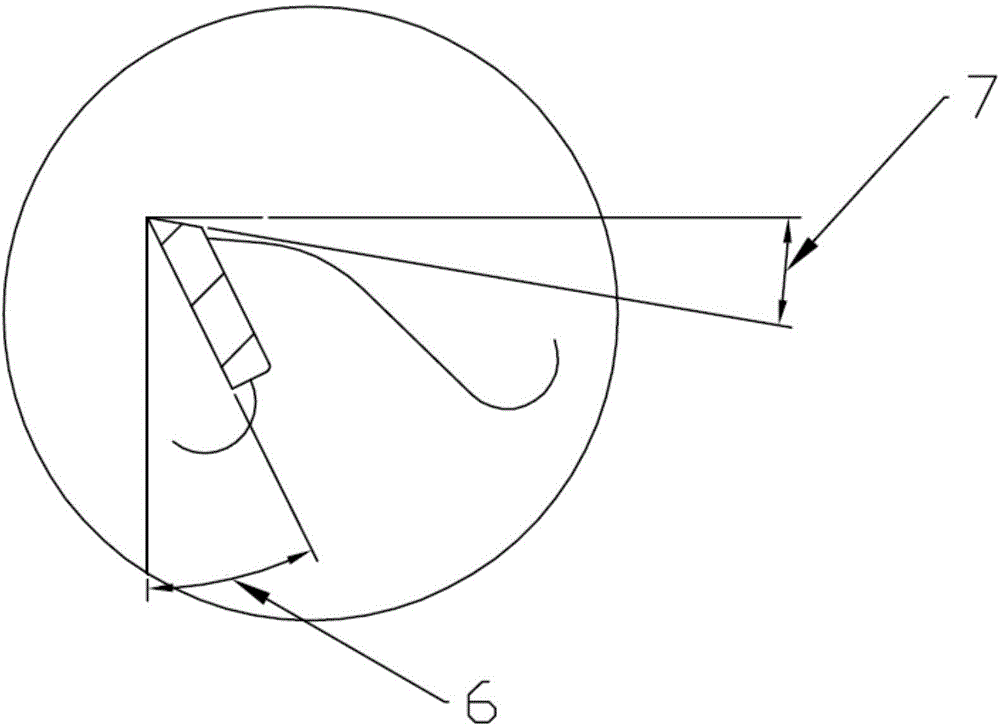

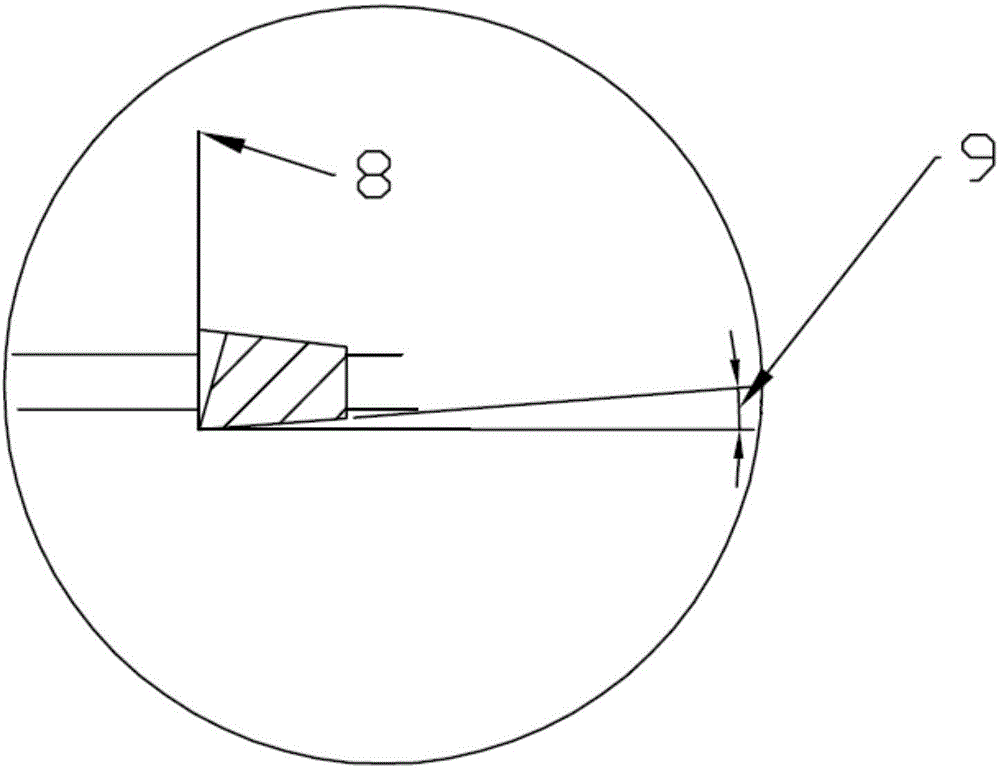

[0028] Wherein, the rake angle 6 between the left edge line of the front end surface of the ...

Embodiment 2

[0031] A saw blade with strong stability, including a saw blade main body 3, a cutting edge 1, a central hole 5, and also includes jump teeth 2 and cooling holes 4, wherein the saw blade main body 3 is in the shape of a disc, and the central hole 5 is located on the saw blade The geometric center of the main body 3, the cutting edge 1 is distributed on the outer circumference of the saw blade main body 3, the skip teeth 2 are evenly distributed on the outer circumference of the saw blade main body 3, the heat dissipation holes 4 are located on the saw blade main body 3 and each heat dissipation hole 4 is evenly distributed on the saw blade body 3 The main body 3 is on a circumference of a concentric circle, the diameter of the cooling hole 4 is 6% of the diameter of the main body 3 of the saw blade, and the diameter of the central hole 5 is 40% of the diameter of the main body 3 of the saw blade.

[0032] Wherein, the rake angle 6 between the left edge line of the front end sur...

Embodiment 3

[0034] A saw blade with strong stability, including a saw blade main body 3, a cutting edge 1, a central hole 5, and also includes jump teeth 2 and cooling holes 4, wherein the saw blade main body 3 is in the shape of a disc, and the central hole 5 is located on the saw blade The geometric center of the main body 3, the cutting edge 1 is distributed on the outer circumference of the saw blade main body 3, the skip teeth 2 are evenly distributed on the outer circumference of the saw blade main body 3, the heat dissipation holes 4 are located on the saw blade main body 3 and each heat dissipation hole 4 is evenly distributed on the saw blade body 3 The main body 3 is on a concentric circle, the diameter of the cooling hole 4 is 4% of the diameter of the main body 3 of the saw blade, and the diameter of the central hole 5 is 32% of the diameter of the main body 3 of the saw blade.

[0035] Wherein, the rake angle 6 between the left edge line of the front end surface of the cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com