Moving container type self-weighing hydraulic packing machine

A box-type, weighing mechanism technology, applied in the direction of presses, food science, tobacco, etc., can solve the problems of high labor intensity and low work efficiency of mobile balers, reduce labor intensity, solve the problem of high labor intensity, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

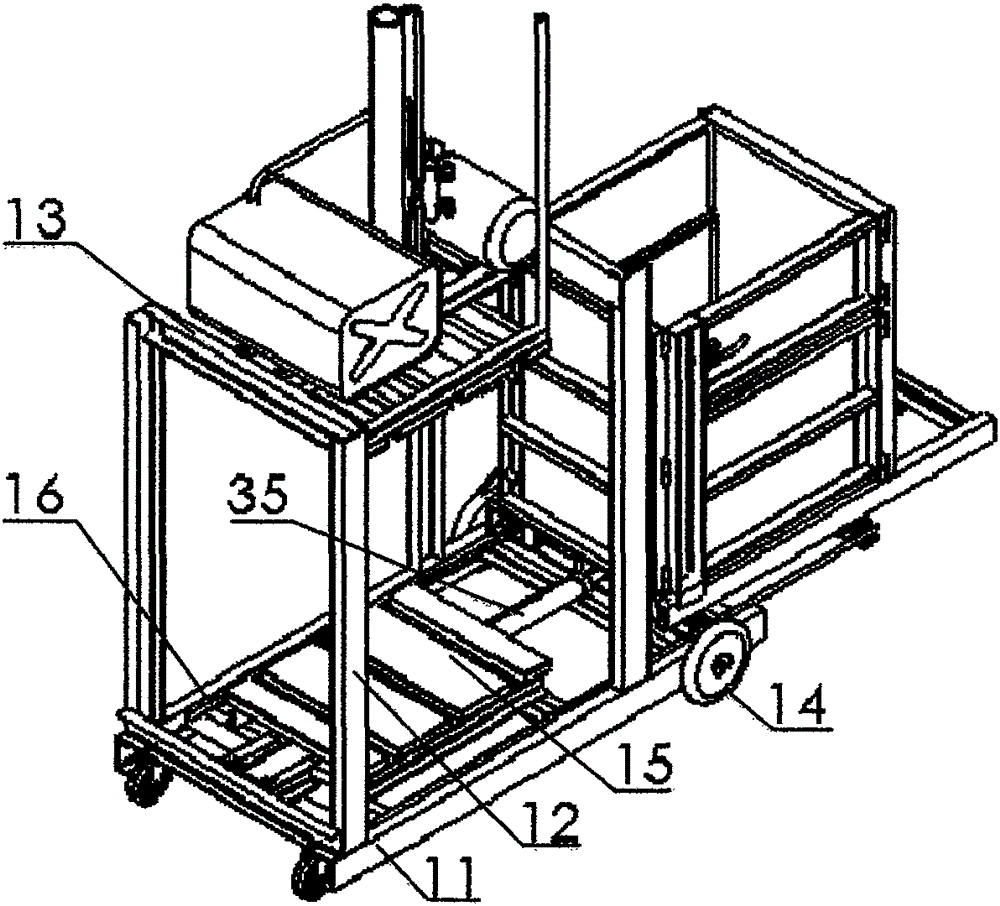

[0022] A mobile box-type self-weighing hydraulic baler, which is mainly composed of a mobile frame 1, a weighing mechanism 2, a mobile box 3, a hydraulic system 4 and an electrical system, and is characterized by:

[0023] 1. The mobile frame 1 is divided into three parts: a bottom basket frame 11, a column 12, and an upper frame 13. A movable wheel 14 is installed under the bottom basket frame 11. The movable wheel 14 can be a fixed wheel or a universal wheel. Under the action of the moving wheels 14, the moving frame 1 can move freely back and forth; the bottom basket frame 11 is provided with a lower pressing head 15, and the lower pressing head 15 is provided with a number of front and rear grooves for placing the bundles Wrap rope; the front and rear sides of the lower pressing head 15 are provided with rails 16, and the upper frame 13 is connected with the bottom basket frame 11 through the upright 12 (see figure 1 ), the number of uprights can be determined as needed, eithe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com