Scroll compressor

A technology for compressors and scroll disks, applied in the field of compressors, can solve problems such as difficult manufacturing, composite or two-stage scroll compressors that have not been widely developed, and reduce input loss, enhance compressor efficiency, and increase volume ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

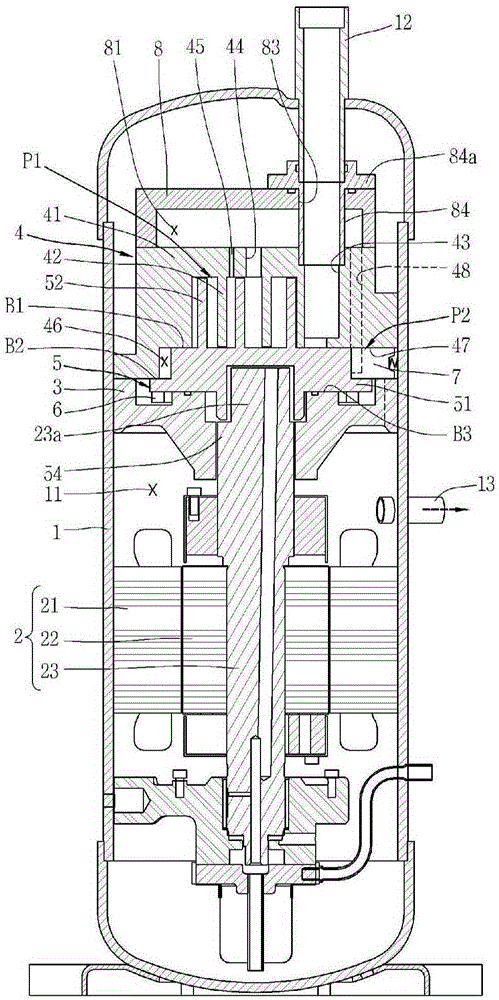

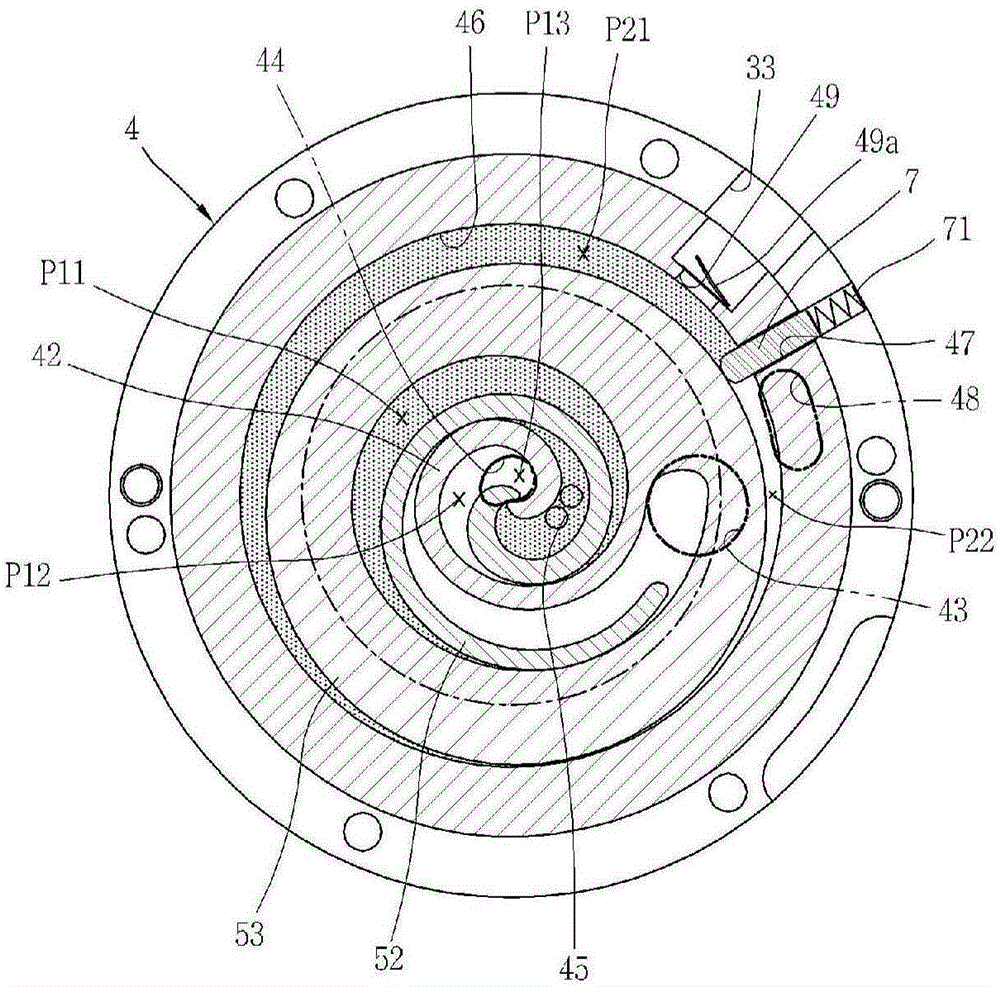

[0068] Hereinafter, a compressor according to the present disclosure will be described in detail with reference to embodiments shown in the accompanying drawings.

[0069] figure 1 To show a longitudinal sectional view of an example of a two-stage compressor according to the present disclosure, figure 2 to show the basis figure 1 An enlarged longitudinal sectional view of the compression unit in the two-stage compressor of , image 3 for along figure 2 A cross-sectional view of the line "I-I", Figure 4 For fixed scroll and orbiting scroll and according to figure 2 A perspective view of the compression unit detached, and Figure 5 to illustrate the basis of figure 1 Longitudinal cross-sectional view of the refrigerant suction and discharge paths in a two-stage compressor.

[0070] As described above, in the two-stage compressor according to the present disclosure, the driving motor 2 for generating a rotational force in the inner space 11 of the container 1 may be pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com