Manufacturing method of flexible display screen, flexible glass substrate and flexible display screen

A flexible display and flexible glass technology, which is applied in nonlinear optics, semiconductor/solid-state device manufacturing, organic semiconductor devices, etc., can solve the problems of fragile flexible glass substrates and product quality degradation, and achieve excellent water resistance and improve quality , the effect of alleviating stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

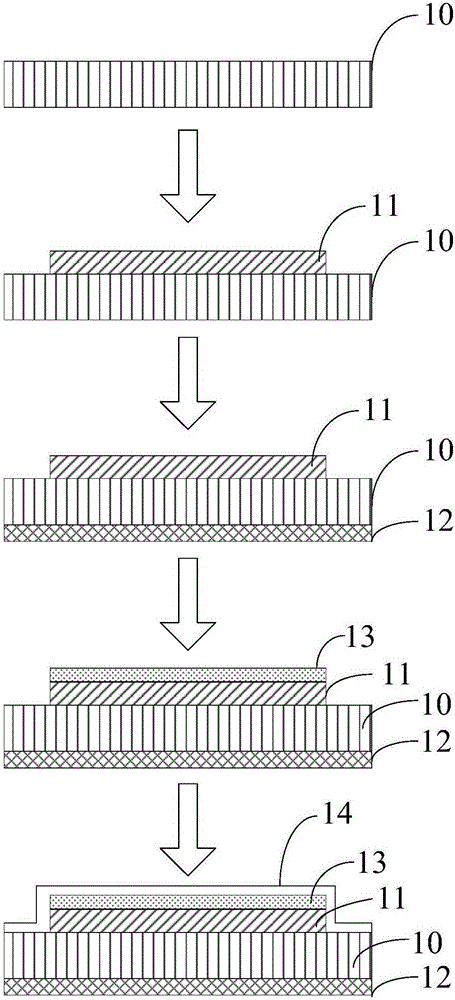

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

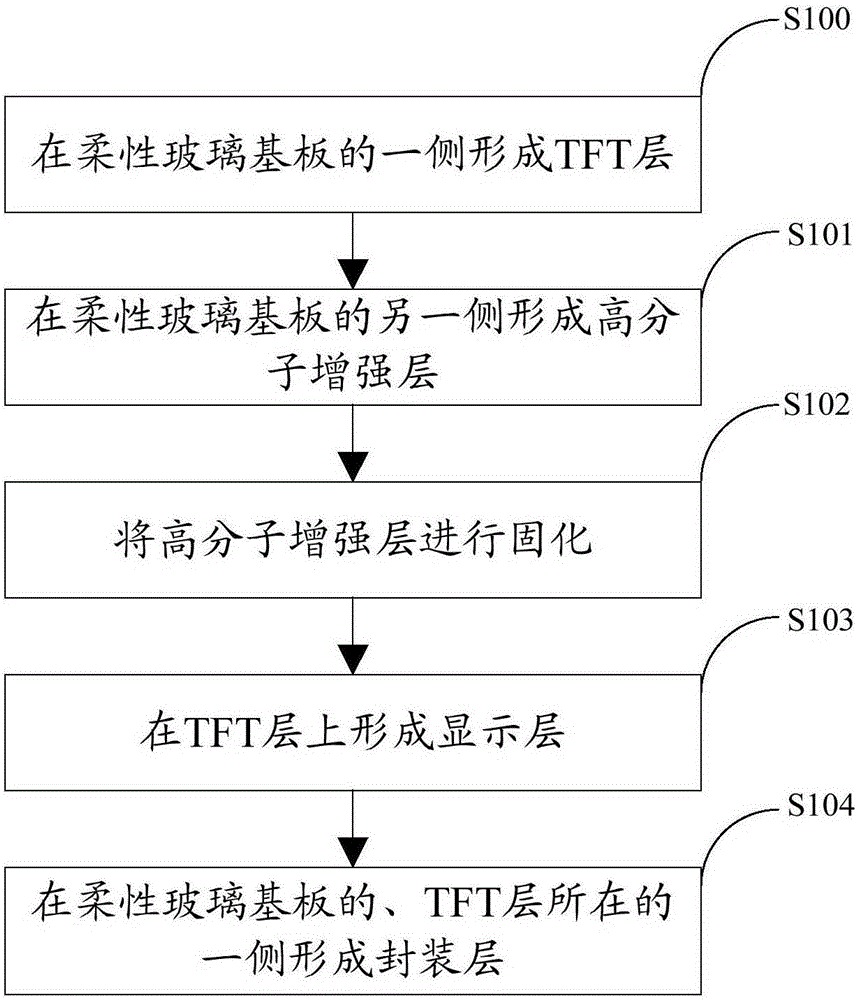

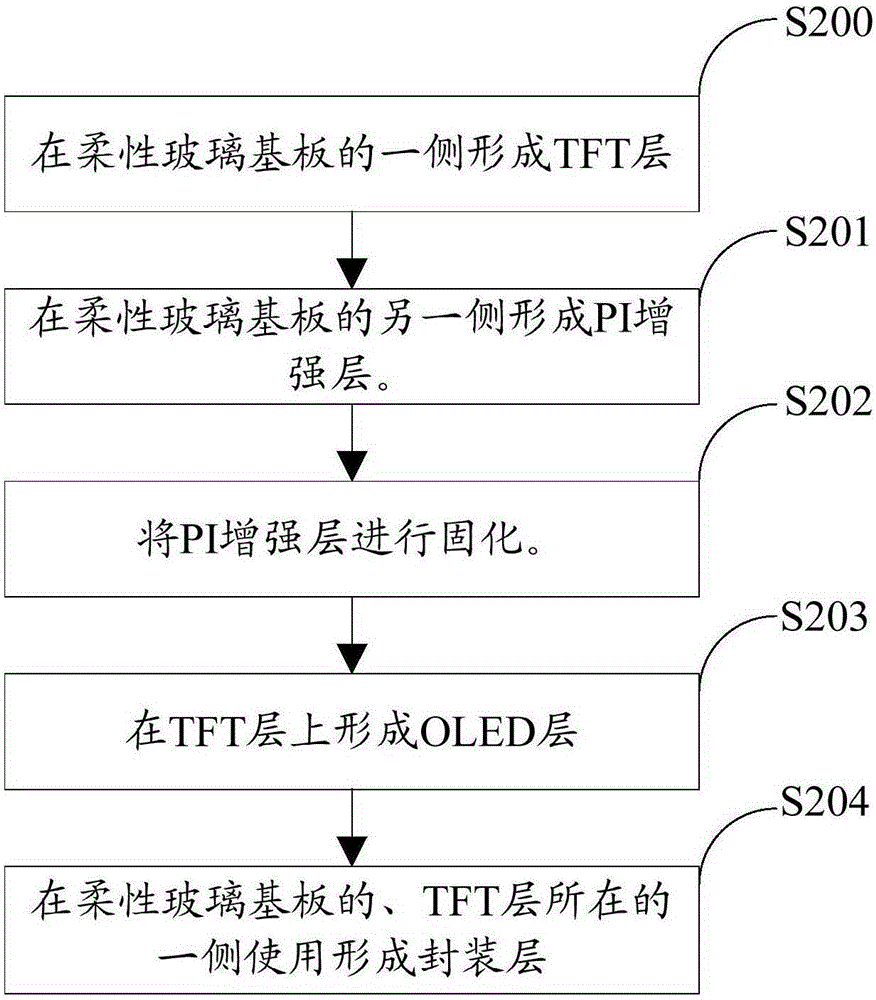

[0024] see figure 1 with figure 2 , the invention provides a method for manufacturing a flexible display, specifically comprising the following steps:

[0025] S100 , forming a TFT layer 11 on one side of the flexible glass substrate 10 .

[0026] The flexible glass substrate 10 is a kind of thin and transparent glass, which can be easily bent by people. TFT (ThinFilmTransistor) is a thin film transistor used to drive the liquid crystal pixels on the display.

[0027] S101 , forming a polymer reinforcement layer 12 on the other side of the flexible glass substrate 10 .

[0028] Glass is a typical brittle material. Although flexible glass can be bent, its compressive strength is still relatively low. There are defects on the surface and inside, and cracks are prone to crack propagation under the action of external force and environmental ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com