an integrated stove

A technology of integrated stove and smoking board, applied in the field of kitchen equipment and integrated stove, can solve the problems of corrosion and damage of integrated stove parts, pollution of kitchen, and return of oil fume, so as to achieve a clean and healthy environment, complete oil fume filtration, and ensure health and hygiene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

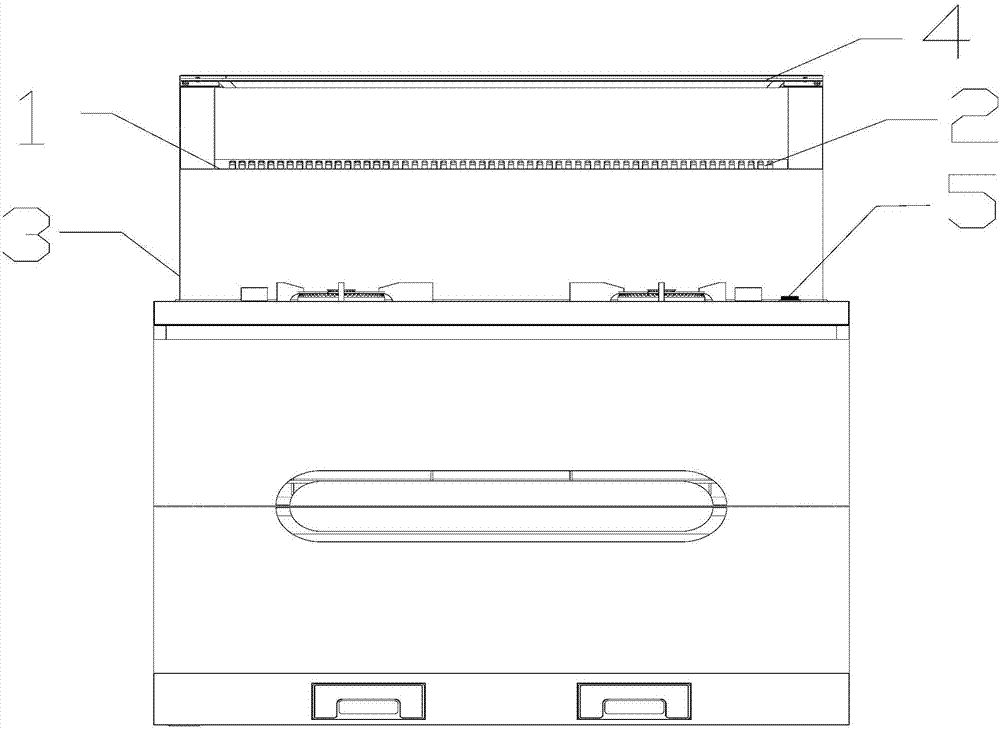

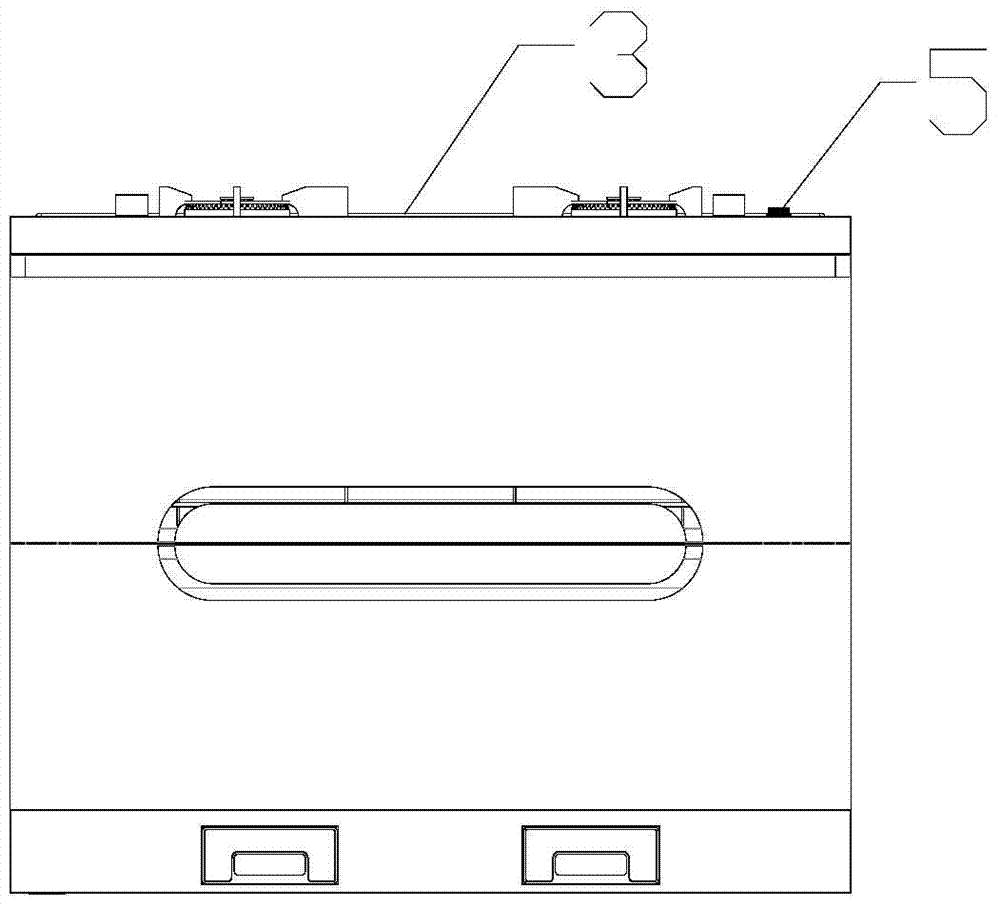

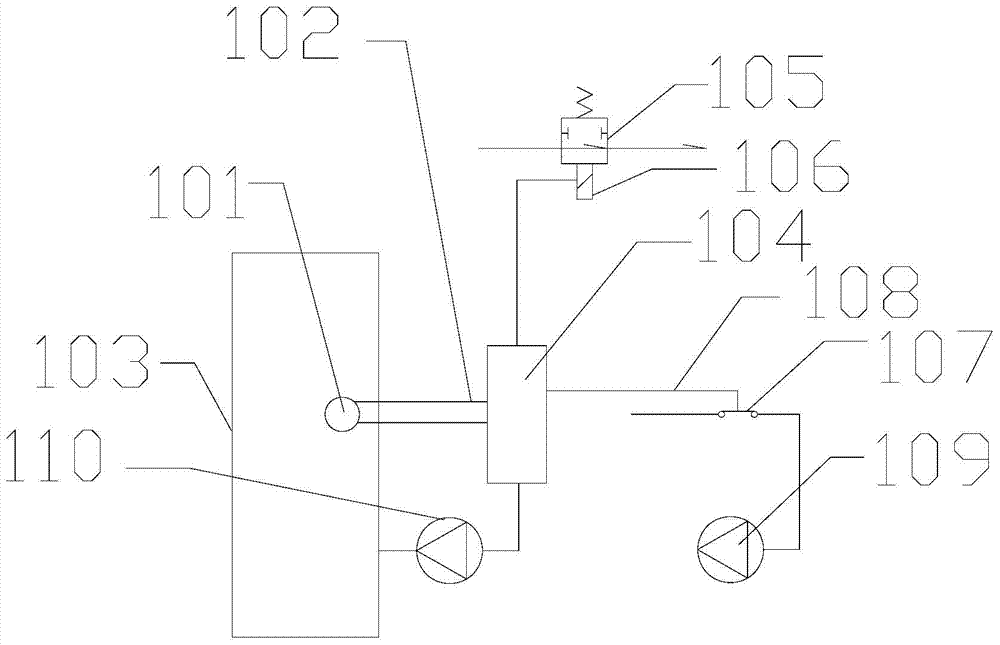

[0022] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 , an integrated cooker according to the present invention, comprising an open flame protection system 1, a smoking plate 2, an automatic lifting structure 3, an automatic flap structure 4 for the smoking plate, and a high-temperature heating and purification structure 5. The open flame protection system 1 includes a temperature sensor 101, a signal Optical fiber 102, oil fume exhaust system 103, electrical control center 104, solenoid valve 105, gas main pipe 106, electric control switch 107, electric wires 108, exhaust fan 109, blower 110, the temperature sensor 101 is fixed on the flue gas of the oil fume exhaust system 103 Near the suction port, the temperature sensor 101 is connected with a signal optical fiber 102, the other end of the signal optical fiber 102 is connected with the electrical control center 104, the solenoid valve 105 is fixed on the gas main pipe 106, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com