Technique for constructing water-saving moisture-preserving maintenance film and geogrid combined maintenance cement stabilizing structural layer

A technology of geogrid and construction technology, which is applied in the field of construction of a water-saving moisturizing maintenance film and a composite health-preserving water-stabilizing structure layer of a geogrid, can solve the problems of affecting the health preservation quality, affecting the strength growth, easy loss of materials, etc., so as to improve the maintenance The effect of quality, saving project cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

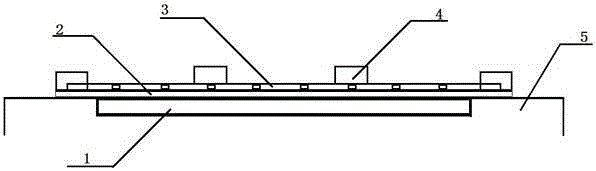

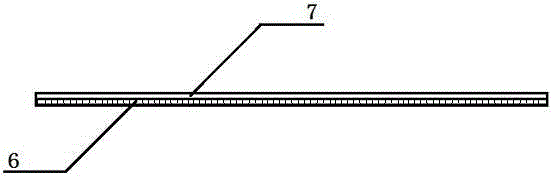

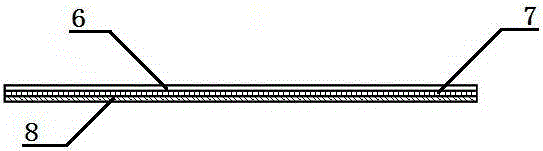

[0021] First of all, construction technicians are familiar with the construction drawings, and understand the geometric dimensions and line types of the construction road sections. The second is the preparation of materials and equipment. According to the construction plan, prepare a sufficient number of concrete water-saving and moisturizing maintenance films 2 and geogrids 3. Membrane 2 was tested and met acceptance criteria. Reasonably organize sprinklers, sprayers, etc. required for construction, and the specific operations are as follows.

[0022] (1) Layer wetting: After the water-stabilizing structure layer 1 is rolled and formed, the road surface must be moistened first before curing. In actual operation, according to the water loss at the layer, methods such as no water replenishment, partial water replenishment, and watering can be adopted; if no water replenishment is used, a water-saving moisturizing maintenance film can be directly laid. This situation is suitabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com