Fiber grating sensing-based asphalt pavement compaction monitoring method

A fiber grating and asphalt pavement technology, applied in the direction of roads, roads, road repairs, etc., can solve the problem of not controlling the number of asphalt pavement compaction in real time, and achieve significant promotion and application value, reduce early-stage diseases, and improve construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

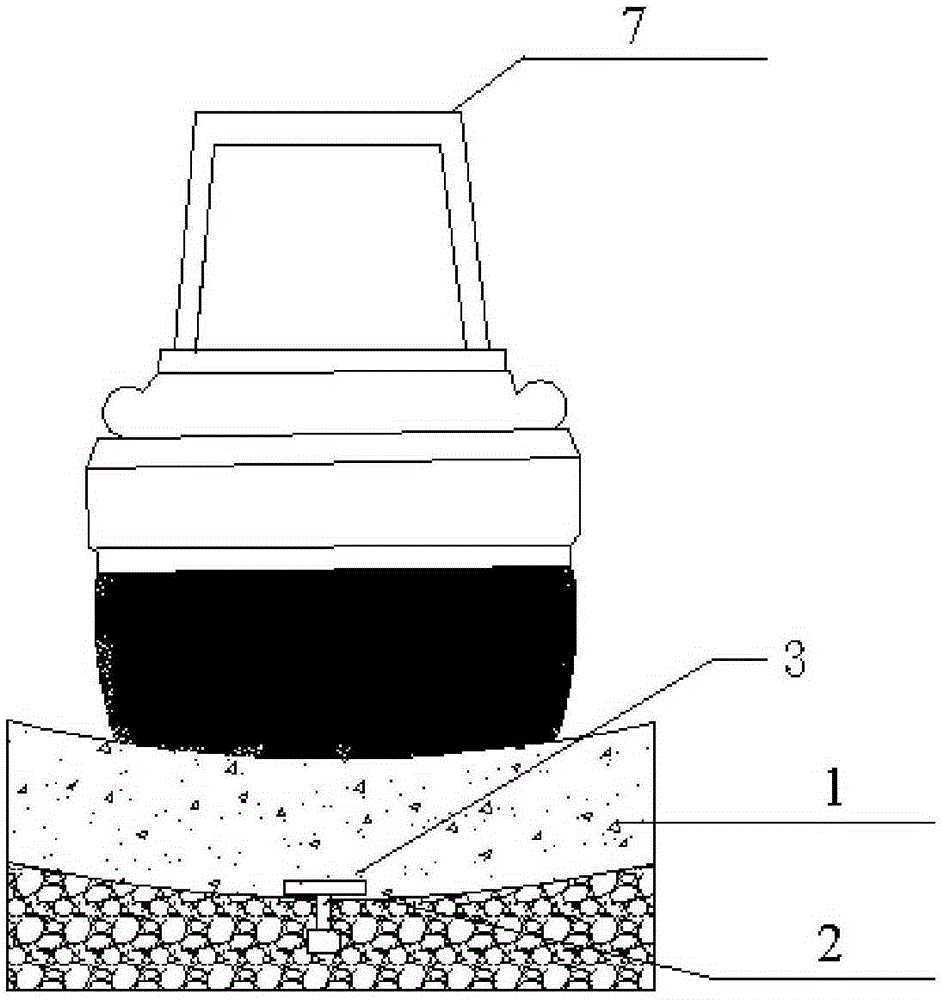

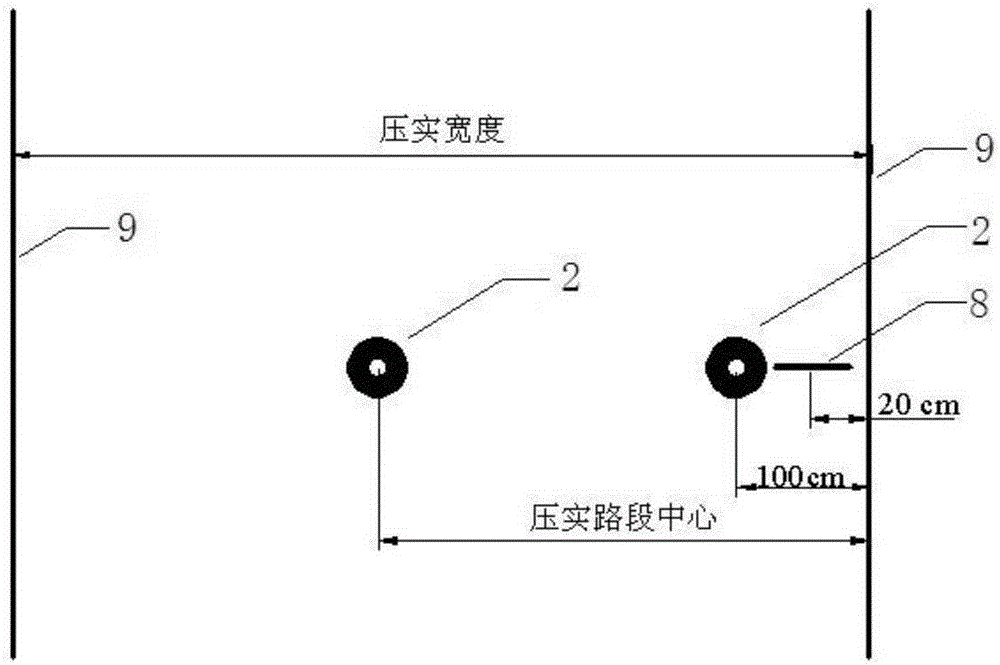

[0046] Specific implementation mode 1, refer to figure 1 This embodiment is described in detail. A method for monitoring asphalt pavement compaction based on fiber Bragg grating sensing described in this embodiment is implemented based on an asphalt pavement compaction monitoring device. The asphalt pavement compaction monitoring device includes n optical fibers Grating vertical strain sensor 2, m fiber grating temperature sensors 8, fiber grating demodulator 10, central processing unit 11 and cables; the data signal input and output ends of the fiber grating vertical strain sensor 2 are connected to the fiber grating demodulator through cables 10 data signal output and input terminals; the data signal input and output terminals of the fiber grating temperature sensor 8 are connected to the data signal output and input terminals of the fiber grating demodulator 10 through cables; the data output terminals of the fiber grating demodulator 10 are connected to the central processi...

specific Embodiment approach 2

[0059] Specific implementation mode two, refer to Figure 4 Describe this embodiment. This specific embodiment is a further description of the asphalt pavement compaction monitoring method based on fiber Bragg grating sensing described in the first specific embodiment. In this embodiment,

[0060] The central processing unit 11 includes a vehicle photographing module 12, an image recognition and image quantity statistics module 13, a data storage and processing module 14 and a display module 15;

[0061] The vehicle photographing module 12 is used to take pictures when the b road roller 7 rolls the nth fiber grating vertical strain sensor 2 or the mth fiber grating temperature sensor 8, and sends the image obtained by taking pictures to the image recognition module 13;

[0062] The image recognition and image quantity statistics module 13 is used to identify the received images, and count the number of images of the b-th road roller 7 rolling the n-th fiber grating vertical st...

specific Embodiment approach 3

[0065] Specific Embodiment 3. This specific embodiment is a further description of a method for monitoring asphalt pavement compaction based on fiber Bragg grating sensing described in Specific Embodiment 2. In this embodiment,

[0066] The central processing unit 11 in the step 3 processes the received data and displays the rolling result to obtain a reasonable number of rolling times. The process is as follows:

[0067] Step 31. When the b road rollers 7 are running at a constant speed and working at the same time, the central processing unit 11 numbers the b road rollers, and the image recognition and image quantity statistics module 13 in the central processing unit 11 counts the b'th road roller 7 rolling the first The rolling times a of the n fiber grating vertical strain sensors 2 or the m fiber grating temperature sensor 8; a is a positive integer;

[0068] Step three and two, the data storage and processing module 14 in the central processing unit 11 makes the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com