Method for recovering rare earths from vacuum-calcium-thermic-reduction rare-earth slag

A rare earth and vacuum technology, applied in the direction of improving process efficiency, can solve the problem that rare earth is difficult to be leached by acid, and achieve the effect of superior treatment effect, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

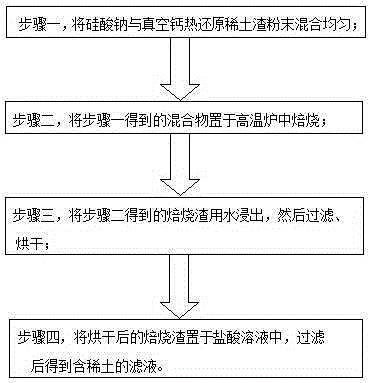

Method used

Image

Examples

Embodiment 1

[0027] Take 50g of calcareous rare earth slag, in which the content of REO is 5.61%, the mass ratio of sodium silicate to reducing slag is 1.5:1, the roasting temperature is 850°C, take it out after 1.5h after the roasting reaction, soak the roasted slag in water, filter and dry , the filter residue was leached for 1.5h under the conditions of hydrochloric acid concentration of 3mol / L, liquid-solid ratio of 20:1, and reaction temperature of 50°C. The rare earth content in the residue was measured to be 0.29% by filtration and drying, and the rare earth leaching rate was 98.65%.

Embodiment 2

[0029] Take 100 g of calcithermic reduction rare earth slag, wherein the content of REO is 5.61%, the mass ratio of sodium silicate to reduction slag is 1:1, the roasting temperature is 1000°C, take out after 2 hours of roasting reaction, soak the roasted slag in water, filter and dry, The filter residue was leached for 3 hours under the conditions of hydrochloric acid concentration of 4mol / L, liquid-solid ratio of 9:1, and reaction temperature of 70°C. After filtration and drying, the rare earth content in the residue was measured to be 0.16%, and the rare earth leaching rate was 99.36%.

Embodiment 3

[0031] Take 150 g of calcithermic reduction rare earth slag, in which the content of REO is 5.61%, the mass ratio of sodium silicate to reduction slag is 0.5:1, the roasting temperature is 750°C, take out after 3 hours of roasting reaction, soak the roasted slag in water, filter and dry, The filter residue was leached for 4 hours under the conditions of hydrochloric acid concentration 0.5mol / L, liquid-solid ratio 5:1, and room temperature. After filtration and drying, the rare earth content in the residue was measured to be 2.11%, and the rare earth leaching rate was 92.14%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com