Method for harvesting microalgae through alkalescence flocculation-foam separation and separation device

A technology of foam separation and flocculation, applied in enzymology/microbiology devices, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problems of large amount of foam additives, unsuitable for industrial scale-up, high production capacity, etc. The effect of reducing consumption and additive consumption, strengthening gas-liquid-solid contact mass transfer, and reducing the accumulation of inorganic ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

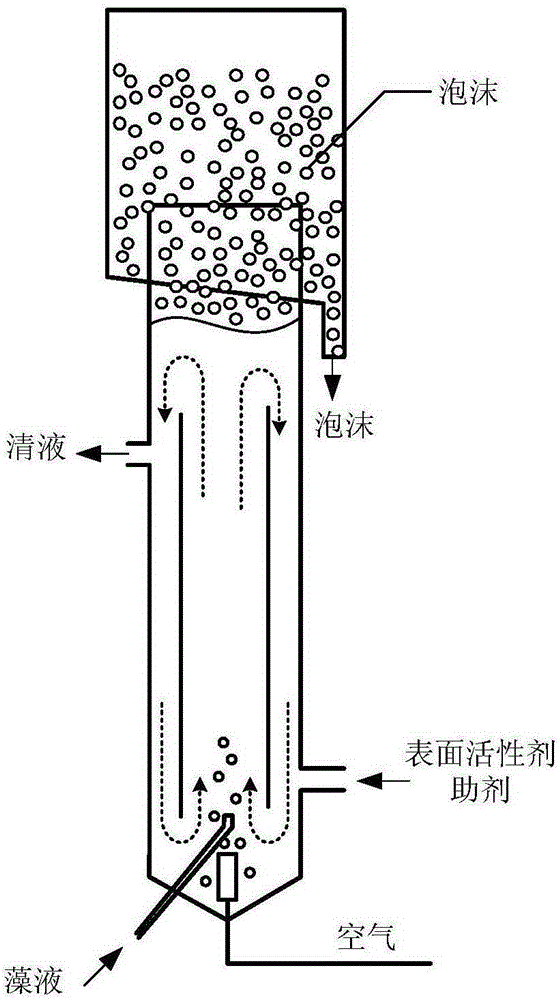

Image

Examples

Embodiment 1

[0079] Embodiment 1, weak alkaline flocculation-foam separation continuous harvesting of microalgae:

[0080] 1) Marine Chlorella (MarineChlorella), with a diameter of 3 to 8 μm, is cultivated in the marine chlorella culture medium (adopting f / 2 improved seawater medium, the pH value of the culture medium is 8.4, referred to as the algae culture medium) , the algae cell concentration in the marine Chlorella culture medium was 4.5×10 at the end of the cultivation 7 a / mL;

[0081]2) Using the operation mode of continuous operation, inject the above-mentioned algae culture solution with marine chlorella into the pH adjustment tank I, and add ammonia water (20% by mass fraction) to adjust its pH to 10-10.5; The liquid inlet conduit 1 flows into the settling tank 2 at a flow rate of 60L / h (hydraulic retention time is 1h), and is divided into a flocculated concentrated algae liquid and a supernatant liquid, and the flocculated concentrated algae liquid flows out through the outlet ...

Embodiment 2

[0088] Embodiment 2, weak alkaline flocculation-foam separation continuous harvesting of microalgae:

[0089] The same steps as those in Example 1 were completely adopted, only the flow rate of the culture solution of Chlorella marinae flowing into the settlement tank 2 was changed. When the flow rate of marine chlorella culture solution is different (thereby the hydraulic retention time is different), the separation effect obtained is as shown in table 2, as can be known from table 2: along with the prolongation of hydraulic retention time, higher Recovery and concentration times.

[0090] Table 2. Separation effect of flocculation and sedimentation

[0091] Algae fluid flow (L / h)

Embodiment 3

[0092] Example 3, Weak alkaline flocculation-foam separation intermittent harvesting of microalgae:

[0093] 1) The algae species and culture solution adopted are the same as in Example 1, and the concentration of algae cells in the culture solution of Chlorella marine algae was 4.5×10 when the cultivation ended. 7 a / mL;

[0094] 2) Adopt the operation method of intermittent operation, add 60 L of the above-mentioned marine chlorella culture solution with marine chlorella to the sedimentation tank 2 at a time, and add ammonia water (mass fraction 20%) to adjust its pH to 10 ~10.5; start to settle, so that the settling time of the algae culture solution in the settling tank 2 is 0.5~4h, divided into flocculation concentrated algae liquid and supernatant, the flocculated concentrated algae liquid is extracted through the outlet 4 at the bottom of the settling tank 2, and Store in the intermediate storage tank IV to be separated in the next step; and pass CO into the supernatant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com