A kind of polyhydroxy organic amine water-based drilling fluid shale inhibitor and preparation method thereof

A shale inhibitor and water-based drilling fluid technology, which is applied in the preparation of organic compounds, the preparation of aminohydroxy compounds, and organic chemistry, etc., can solve the problems of large odor and insignificant effect, and achieves simple operation and good inhibition effect. , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

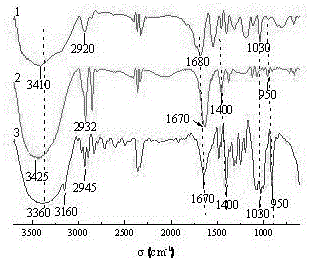

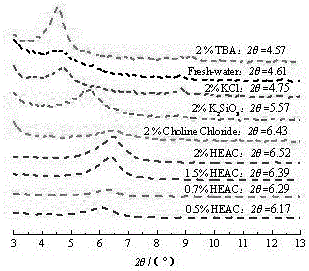

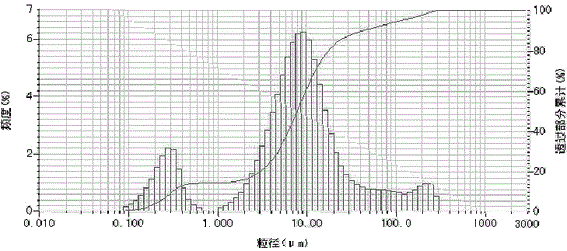

Method used

Image

Examples

Embodiment 1

[0034] Take 0.2 mol of triethanolamine and add 145 ml of absolute ethanol to dissolve in a three-neck flask, pass nitrogen for 10 minutes and then raise the temperature to 55°C, add 0.1 mol of dibromoethane dropwise and reflux for 22 hours. After the reaction, the crude product of the obtained inhibitor was recrystallized using ethyl acetate and absolute ethanol, the volume ratio of ethyl acetate and absolute ethanol was 1.5:8, and the recrystallized product was heated at a temperature of 40 to 50°C After vacuum drying, the refined polyhydroxy organic amine water-based drilling fluid shale inhibitor was obtained, and its melting point was measured to be 47°C.

Embodiment 3

[0036] Take 0.2 mol of triethanolamine and add 160 ml of absolute ethanol to dissolve in a three-neck flask, pass nitrogen for 10 minutes and then raise the temperature to 65°C, add 0.25 mol of dibromoethane dropwise and reflux for 26 hours. After the reaction, the crude product of the obtained inhibitor was recrystallized using ethyl acetate and absolute ethanol, the volume ratio of ethyl acetate and absolute ethanol was 2:8, and the recrystallized product was vacuum-dried at a temperature of 50°C , that is, the refined polyhydroxy organic amine water-based drilling fluid shale inhibitor was measured and its melting point was 46.8°C.

[0037] Example 3:

[0038] Take 0.2 mol of triethanolamine and add 180 ml of absolute ethanol to dissolve in a three-necked flask, pass nitrogen for 10 minutes and then raise the temperature to 57°C, add 0.14 mol of dibromoethane dropwise and reflux for 24 hours. After the reaction, the crude product of the obtained inhibitor was recrystallize...

Embodiment 4

[0040] Take 0.2 mol of triethanolamine and add 190 ml of absolute ethanol to dissolve in a three-necked flask, pass nitrogen for 10 minutes and then raise the temperature to 60°C, add 0.2 mol of dibromoethane dropwise and reflux for 23 hours. After the reaction, the crude product of the obtained inhibitor was recrystallized using ethyl acetate and absolute ethanol, the volume ratio of ethyl acetate and absolute ethanol was 1.6:8.1, and the recrystallized product was vacuum-dried at 45°C , that is, the refined polyhydroxy organic amine water-based drilling fluid shale inhibitor was measured and its melting point was 46.5°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com