Preparation method and product of oil-like drilling fluid

An oil-based drilling fluid, polyamine inhibitor technology, applied in drilling compositions, chemical instruments and methods, etc., can solve inhibition, drilling rate and maintenance limitations, limit oil-based mud non-environmentally friendly water-based drilling Liquid use and other issues, to achieve excellent salt resistance and inhibition, excellent lubricity and anti-sticking properties, prevent hydration and dispersion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

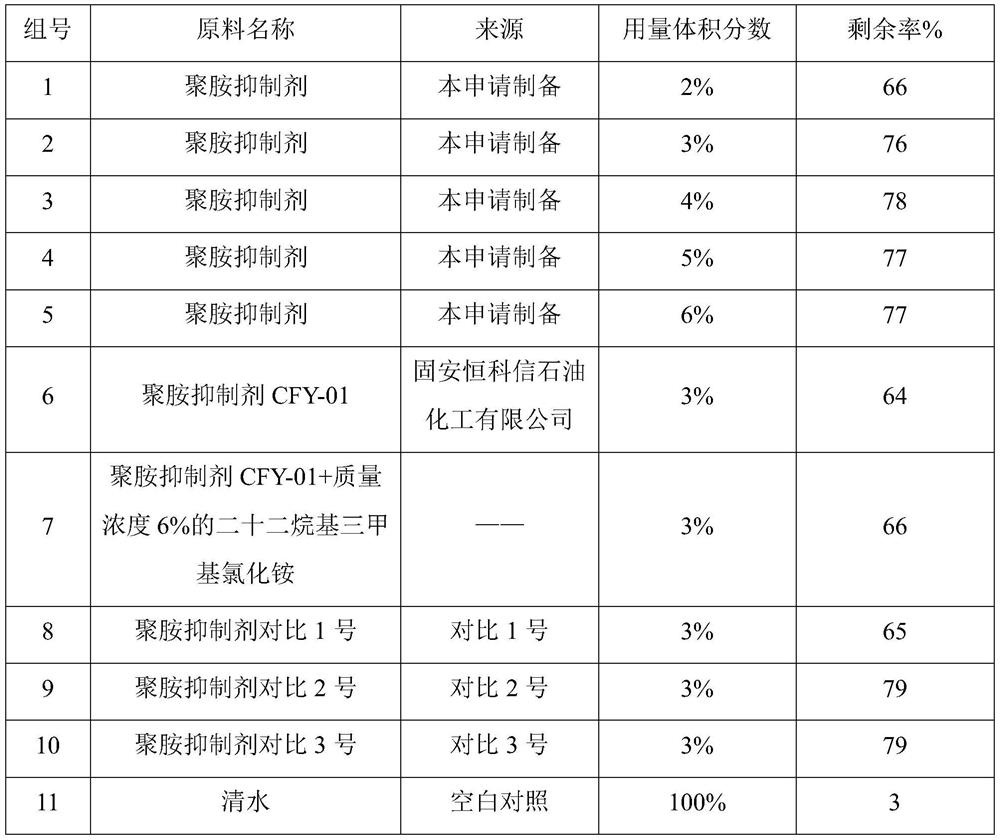

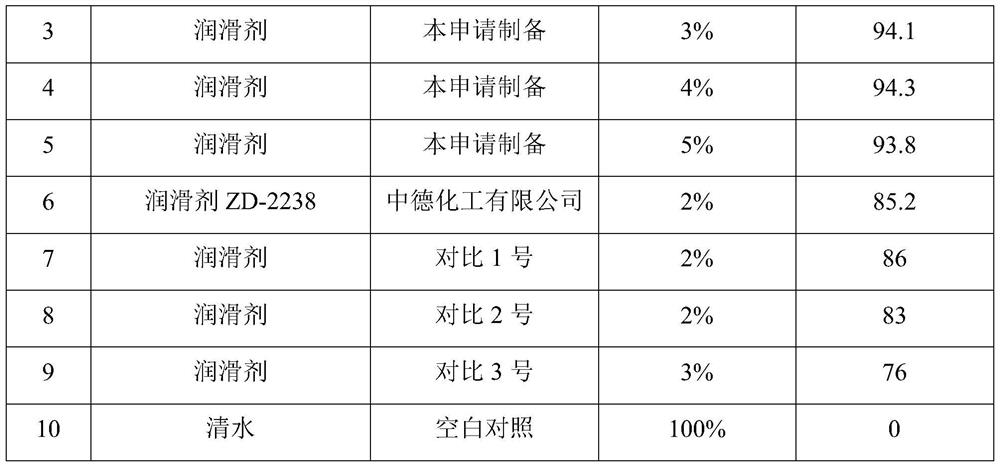

Examples

Embodiment 1

[0064] The preparation method of oil-like drilling fluid is mainly prepared by mixing the following components:

[0065] Polyamine inhibitors, cationic polyacrylamide, low viscosity polyanionic cellulose, xanthan gum, lubricants, and water, mixed evenly, wherein the final concentration of each component of the oil-like drilling fluid is: the volume fraction of the polyamine inhibitor is 2%, the mass concentration of the cationic polyacrylamide is 5kg / m 3 The mass concentration of the low viscosity polyanionic cellulose is 5kg / m 3 The mass concentration of xanthan gum is 1kg / m 3 The volume fraction of the lubricant is 1%.

[0066] Among them, polyamine inhibitors, lubricants are prepared by the method of the present application.

Embodiment 2

[0068] The preparation method of oil-like drilling fluid is mainly prepared by mixing the following components:

[0069] Polyamine inhibitors, cationic polyacrylamide, low viscosity polyanionic cellulose, xanthan gum, lubricants, and water, wherein the final concentration of each component in the oil-based drilling fluid is: the volume fraction of the polyamine inhibitor is 4%, the mass concentration of the cationic polyacrylamide is 10kg / m 3 The mass concentration of the low viscosity polyanionic cellulose is 15kg / m 3 The mass concentration of xanthan gum is 5kg / m 3 The volume fraction of the lubricant is 3%.

[0070] Among them, polyamine inhibitors, lubricants are prepared by the method of the present application.

Embodiment 3

[0072] The preparation method of oil-like drilling fluid is mainly prepared by mixing the following components:

[0073]Polyamine inhibitors, cationic polyacrylamide, low viscosity polyanionic cellulose, xanthan gum, lubricants, and water, wherein the final concentration of each component of the oil-like drilling fluid is: the volume fraction of the polyamine inhibitor is 3%, the mass concentration of the cationic polyacrylamide is 8kg / m 3 The mass concentration of the low viscosity polyanionic cellulose is 8 kg / m 3 The mass concentration of xanthan gum is 3kg / m 3 The volume fraction of the lubricant is 2%.

[0074] Among them, polyamine inhibitors, lubricants are prepared by the method of the present application.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com