Graphene-doped waterborne epoxy zinc-containing anti-corrosion primer and preparation method thereof

A technology of water-based epoxy and anti-corrosion primer, applied in the field of coatings, can solve problems such as difficult to meet anti-corrosion requirements, and achieve good drying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

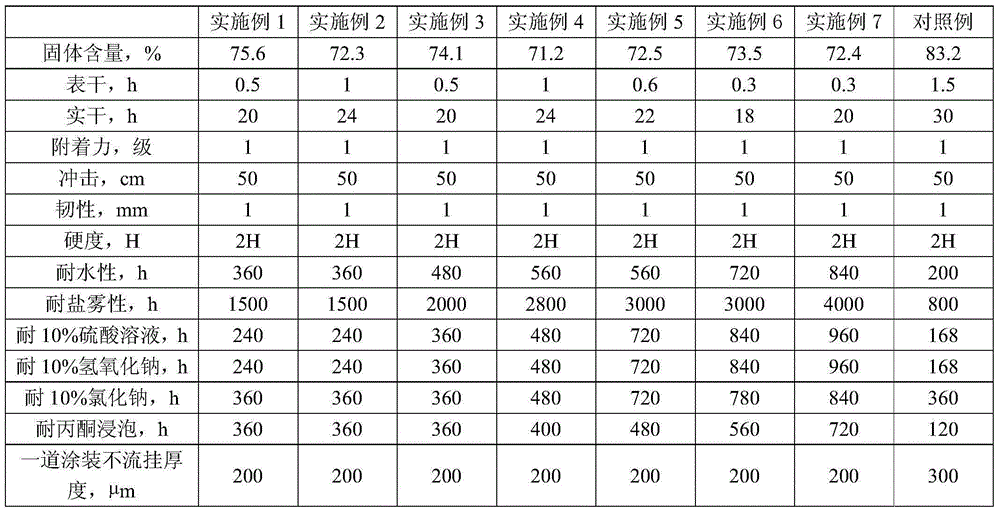

Examples

Embodiment 1

[0036] A waterborne epoxy zinc-containing anticorrosion primer doped with graphene, composed of A component and B component in a weight ratio of 25:1, A component includes the following components in parts by weight: epoxy curing agent 15 parts, 8 parts of titanium dioxide, 2 parts of water-based aluminum silver paste, 40 parts of zinc powder, 2 parts of graphene, 10 parts of nano-barium sulfate, 7 parts of zinc phosphate, 5 parts of iron-titanium powder, 0.5 parts of dispersant, defoamer 0.2 parts, 0.1 parts of anti-foaming agent, 8.5 parts of co-solvent, 0.1 parts of wetting agent, 0.5 parts of neutralizing agent, 0.3 parts of hydrated magnesium silicate, 0.5 parts of organic bentonite, 0.5 parts of anti-flash rust agent, 5 parts of chlorinated polypropylene Parts, 100 parts of deionized water; B component is water-based epoxy resin emulsion.

[0037] The co-solvent is ethylene glycol monobutyl ether.

[0038] In the preparation method of the above graphene-doped waterborne...

Embodiment 2

[0040] A water-based epoxy zinc-containing anticorrosion primer doped with graphene, composed of A component and B component in a weight ratio of 15:1, A component includes the following components in parts by weight: epoxy curing agent 18 parts, 8 parts of titanium dioxide, 2 parts of water-based aluminum silver paste, 25 parts of zinc powder, 3.5 parts of graphene, 8 parts of nano-barium sulfate, 10 parts of zinc phosphate, 5 parts of iron-titanium powder, 0.3 parts of dispersant, defoamer 0.1 part, 0.2 part of antifoaming agent, 9 parts of cosolvent, 0.3 part of wetting agent, 0.6 part of neutralizing agent, 0.4 part of hydrated magnesium silicate, 0.4 part of organic bentonite, 0.8 part of anti-flash rust agent, 7 parts of chlorinated polypropylene Parts, 165 parts of deionized water; B component is water-based epoxy resin emulsion.

[0041] The co-solvent is ethylene glycol monobutyl ether.

[0042] In the preparation method of the above graphene-doped waterborne epoxy z...

Embodiment 3

[0044] A waterborne epoxy zinc-containing anticorrosion primer doped with graphene, composed of A component and B component in a weight ratio of 35:1, A component includes the following components in parts by weight: epoxy curing agent 20 parts, 10 parts of titanium dioxide, 1 part of water-based aluminum-silver paste, 32 parts of zinc powder, 5 parts of graphene, 5 parts of nano-barium sulfate, 5 parts of zinc phosphate, 10 parts of iron-titanium powder, 0.3 parts of dispersant, defoamer 0.2 parts, 0.2 parts of anti-foaming agent, 9 parts of co-solvent, 0.2 parts of wetting agent, 0.8 parts of neutralizing agent, 0.3 parts of hydrated magnesium silicate, 0.5 parts of organic bentonite, 0.8 parts of anti-flash rust agent, 8 parts of chlorinated polypropylene Parts, 180 parts of deionized water; B component is water-based epoxy resin emulsion.

[0045] The co-solvent is ethylene glycol monobutyl ether.

[0046]In the preparation method of the above graphene-doped waterborne ep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com