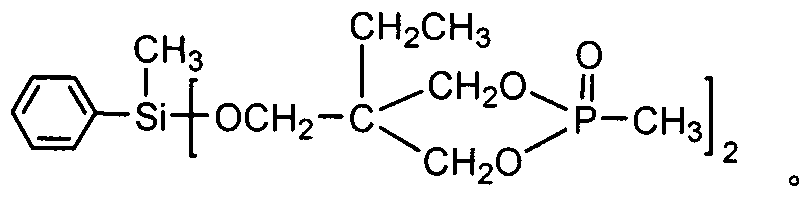

The preparation method of methyl phenyl silicate bis(phosphine heterocyclic methyl) ester compound

A technology of methylphenyldimethoxysilane and methylphenyl, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve material dripping, secondary Combustion and other problems, to achieve the effect of preventing molten dripping, increasing compatibility, and high flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

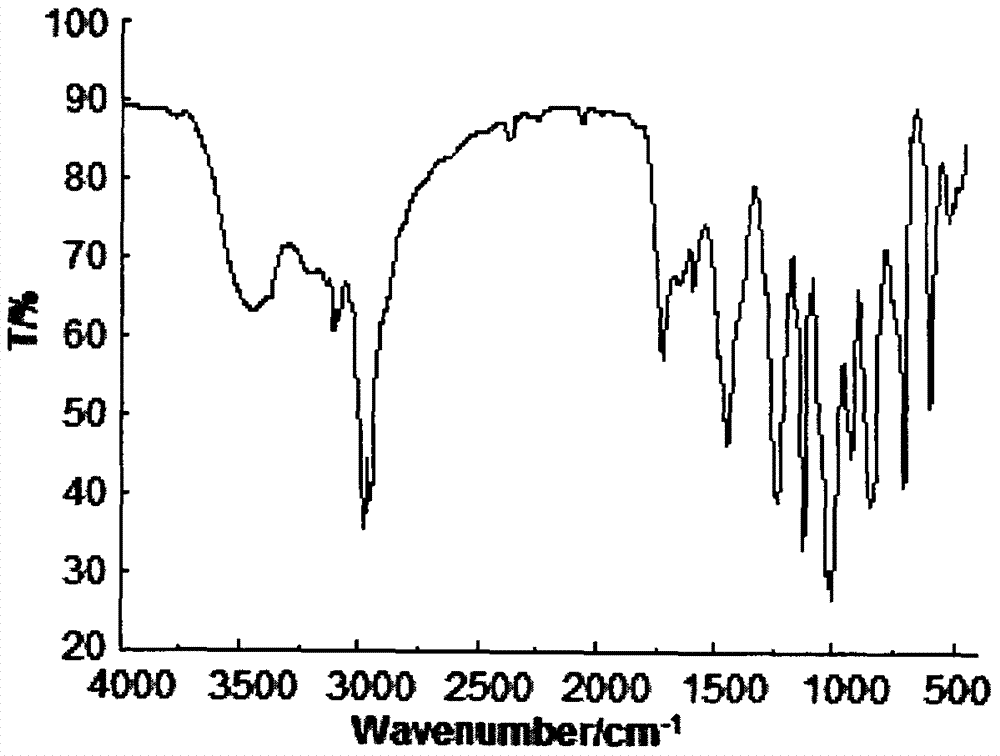

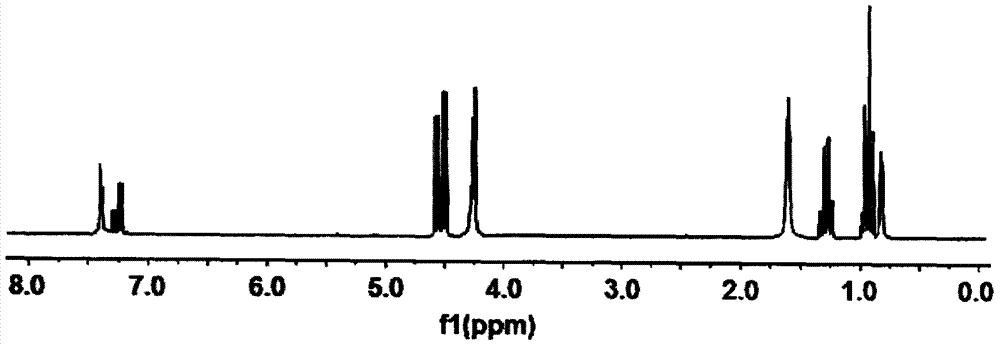

[0025] Example 1 In a 150ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency fractionation device, replace the air in the bottle with nitrogen, and add 22.31g (0.115mol) of 4-hydroxymethyl-4-ethyl-cycloformazol base phosphonate, 9.11g (0.05mol) methylphenyldimethoxysilane, 50ml diethylene glycol dimethyl ether and 0.40g sodium methoxide, the temperature is raised to 160°C, and the temperature at the top of the fractionation column is controlled not to be higher than 65°C , Fractional distillation of the generated methanol, reaction for 12h, after fractional distillation of the theoretical amount of methanol, change to a vacuum distillation device, vacuum distillation to remove diethylene glycol dimethyl ether (recycling), then add 30ml of distilled water, stir to make the solid Disperse in water, filter with suction, and dry to obtain bis(phosphine heterocyclic methyl) methylphenylsilicate as a white solid, with a product yield of 90.0%.

Embodiment 2

[0026] Example 2 In a 150ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency fractionation device, replace the air in the bottle with nitrogen, and add 23.28g (0.12mol) of 4-hydroxymethyl-4-ethyl-cycloformazol base phosphonate, 9.11g (0.05mol) methylphenyldimethoxysilane, 40ml xylene and 0.55g sodium methoxide, heat up to 140°C, control the temperature at the top of the fractionation column to not be higher than 65°C, and fractionate the generated Methanol, reacted 10h, after the theoretical amount of methanol was distilled off, it was changed to a vacuum distillation device, and xylene was removed by vacuum distillation (recycling), and then 50ml of distilled water was added, stirred to make the solid dispersed in water, suction filtered, dried, The white solid methylphenylsilicate bis(phosphine heterocyclic methyl) ester was obtained, and the product yield was 91.2%.

Embodiment 3

[0027] Example 3 In a 100ml four-neck flask equipped with a stirrer, a thermometer, and a high-efficiency fractionation device, replace the air in the bottle with nitrogen, and add 19.40g (0.10mol) of 4-hydroxymethyl-4-ethyl-cycloformazol Base phosphonate, 9.11g (0.05mol) methylphenyldimethoxysilane, 30ml DMF and 0.65g sodium methoxide, raise the temperature to 130°C, control the temperature at the top of the fractionation column to not be higher than 65°C, and fractionate the generated methanol , fractionation reaction 9h, after the theoretical amount of methanol is fractionated, it is changed to a vacuum distillation device, and the DMF (recycled) is removed by vacuum distillation, and then 40ml of distilled water is added, stirred to make the solid dispersed in water, suction filtered, and dried to obtain Bis(phosphine heterocyclic methyl) methyl phenyl silicate as a white solid with a yield of 80.7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com