A high-efficiency synthesis method of dual-silicon source and amine-free large-size mordenite with controllable morphology

A technology of mordenite and synthesis method, applied in the direction of mercerized crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve problems such as complex operation process, long crystallization time of ordinary mordenite, environmental pollution, etc., and achieve separation process The effect of simple operation, convenient recycling of catalytic application, and simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

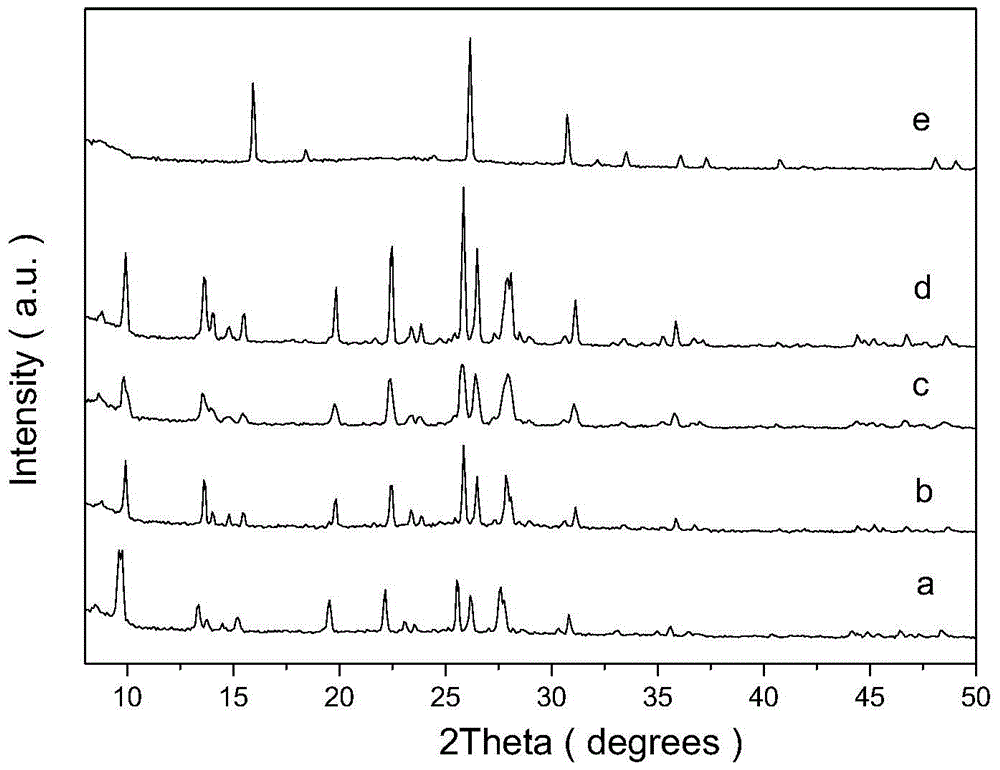

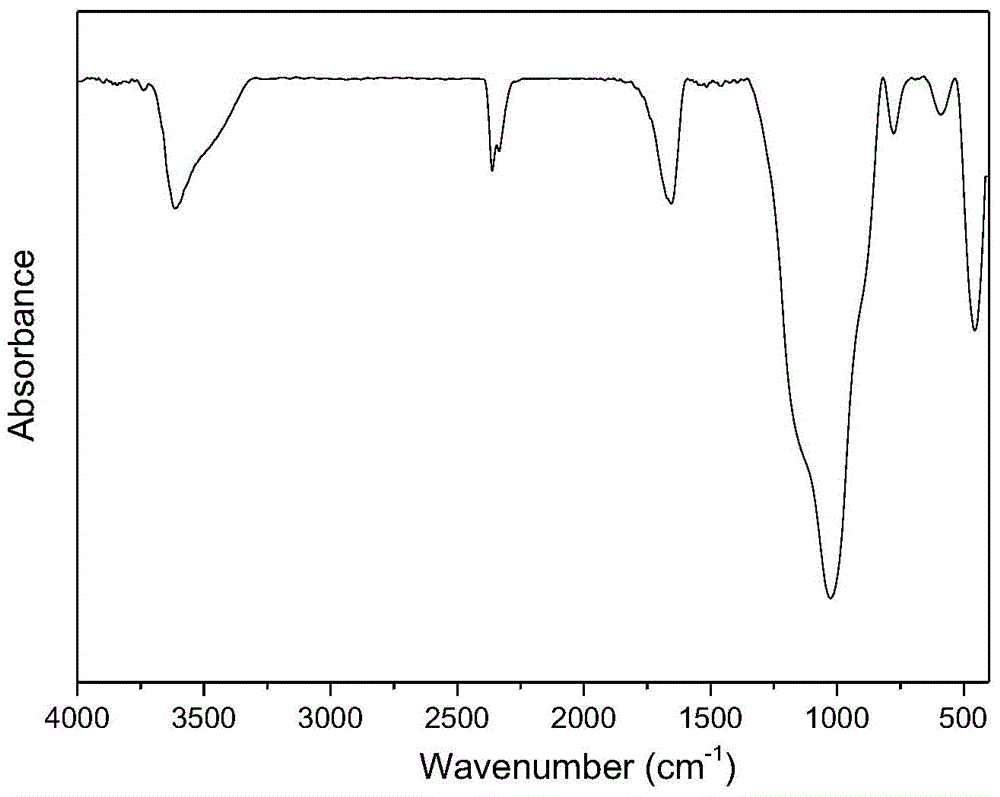

Image

Examples

Embodiment 1

[0033] Water glass is carried out pretreatment, gets 0.32g sodium hydroxide (96wt% NaOH), 0.82g sodium aluminate (41wt% Al 2 o 3 ) was dissolved in 5g deionized water, and the resulting solution was added dropwise to 103.82g water glass (14.74wt% SiO 2 , 5.22 wt% Na 2 O), mechanically stirred for 1 h to obtain a suspension, which was set aside.

[0034] Dissolve 0.59g of sodium hydroxide and 0.79g of sodium aluminate in 30.22g of deionized water, add the suspension aged for 24 hours to the obtained transparent solution, stir mechanically for 0.5 hours, and then add dropwise 15.79g of orthosilicon Ethyl acetate, so that the SiO of two silicon sources (treated water glass and tetraethyl orthosilicate) 2 The molar ratio is 0.83:1, and mechanically stirred for 2 hours to obtain the initial gel of mordenite, wherein the material molar ratio is: 35SiO 2 : 1.17Al 2 o 3 : 10Na 2 O: 750H 2 O. After aging for 24 hours, it was transferred to a polytetrafluoroethylene-lined autoc...

Embodiment 2

[0036] Water glass is carried out pretreatment, gets 0.32g sodium hydroxide (96wt% NaOH), 0.82g sodium aluminate (41wt% Al 2 o 3 ) was dissolved in 5g deionized water, and the resulting solution was added dropwise to 103.82g water glass (14.74wt% SiO 2 , 5.22 wt% Na 2 O), mechanically stirred for 1 h to obtain a suspension, which was set aside.

[0037]Dissolve 0.76g of sodium hydroxide and 0.84g of sodium aluminate in 43.44g of deionized water, add the suspension aged for 24 hours to the obtained transparent solution, stir mechanically for 0.5 hours, and then add dropwise 15.79g of orthosilicon Ethyl acetate, so that the SiO of two silicon sources (treated water glass and tetraethyl orthosilicate) 2 The molar ratio is 0.50:1, and mechanically stirred for 2 hours to obtain the initial gel of mordenite, wherein the material molar ratio is: 35SiO 2 : 1.17Al 2 o 3 : 10Na 2 O: 750H 2 O. After aging for 24 hours, it was transferred to a polytetrafluoroethylene-lined autocl...

Embodiment 3

[0039] Water glass is carried out pretreatment, gets 0.32g sodium hydroxide (96wt% NaOH), 0.82g sodium aluminate (41wt% Al 2 o 3 ) was dissolved in 5g deionized water, and the resulting solution was added dropwise to 103.82g water glass (14.74wt% SiO 2 , 5.22 wt% Na 2 O), mechanically stirred for 1 h to obtain a suspension, which was set aside.

[0040] Dissolve 1.23g of sodium hydroxide and 0.58g of sodium aluminate in 30.22g of deionized water, add the suspension aged for 24 hours to the obtained transparent solution, stir mechanically for 0.5 hours, and then add dropwise 15.79g of orthosilicon Ethyl acetate, so that the SiO of two silicon sources (treated water glass and tetraethyl orthosilicate) 2 The molar ratio is 0.13:1, and mechanically stirred for 2 hours to obtain the initial gel of mordenite, wherein the material molar ratio is: 35SiO 2 : 1Al 2 o 3 : 10Na 2 O: 750H 2 O. After aging for 24 hours, it was transferred to a polytetrafluoroethylene-lined autoclav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com