Closed stock yard intelligent control system and intelligent control method with pre-homogenization function

An intelligent control system, control system technology, applied in the direction of transportation and packaging, loading/unloading, etc., can solve the problems of harsh operating environment, high labor intensity of operators, and low operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

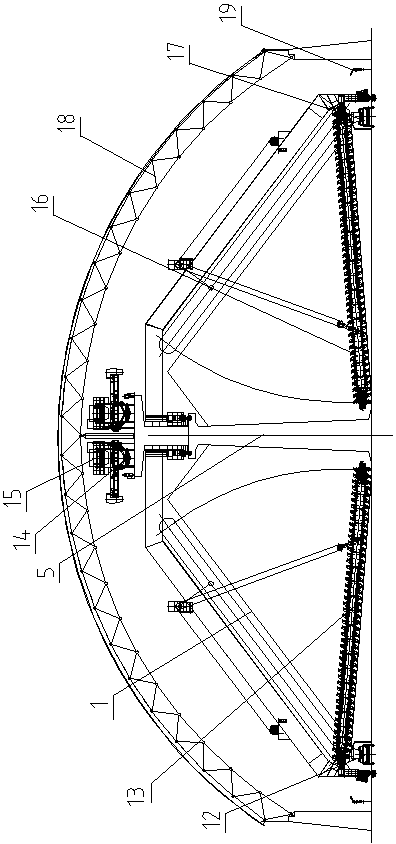

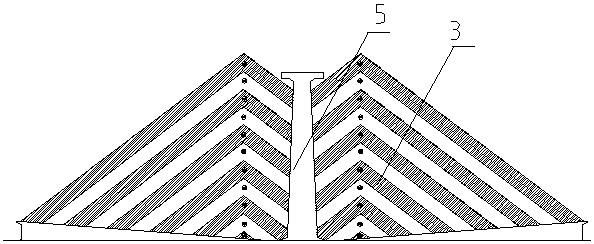

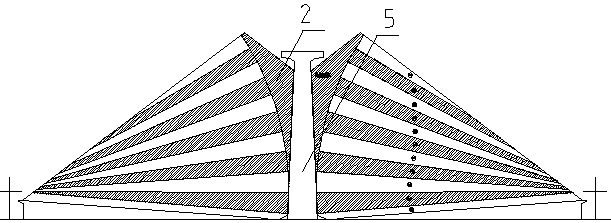

[0035] Such as figure 1 The closed material field with pre-homogenization function shown includes a closed material storage shed 18, a material input system, and a material output system. An intermediate retaining wall 5 is provided in the middle of the closed stockyard, and the intermediate retaining wall 5 has an upper platform and a middle platform. The material input system includes an input tape conveyor 14 arranged on the upper platform and a discharge device 15 that can move along the length direction of the stockyard. One end of the stacking arm belt conveyor of the discharge device 15 stretches out of the upper platform. along. The material output system includes a first reclaiming belt conveyor 12 and a first half-gate scraper reclaimer 13 located on one side of the intermediate retaining wall 5, and a second reclaiming belt conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com