Green brick production system with full-automatic tail end robot assisting stacking function

A robot-assisted and production system technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low safety factor, troublesome manufacturing, lack of detail grasp, etc., and achieve the effect of compact structure, sound function and compact function of the whole line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

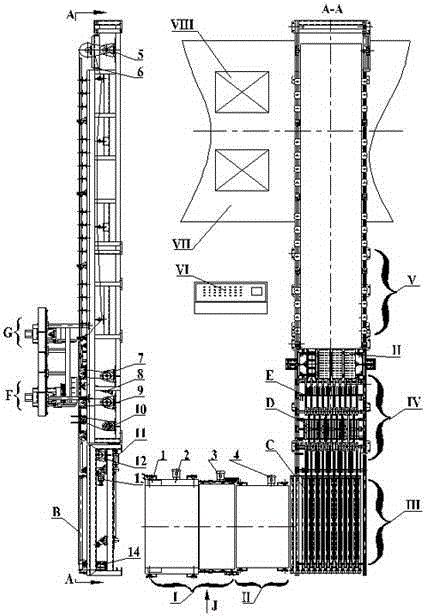

[0030] As shown in the figure, after the brick is cut by the blank cutting machine, it enters the billet connecting section I and runs to the No. 1 waiting billet section II. Due to the limitation of the bandwidth, the mud head of each mud billet falls directly into the drain 1 on the billet connecting section I after leaving the billet cutter. The lower conveyor belt conveys to the extruder for further processing. When the wire cutting of the front side blank cutting machine breaks, the brick adobe close to the wire cutting place in the cut out mud strip cannot be cut normally, so a bad mud strip grows. The entire conveyor belt rises, so the bad mud strips transmitted from the front side fall on the lower side of the conveyor belt, and are transported to the extruder together with the mud heads falling from the front side for further processing. Both the control motor 2 of the billet conveying section at the front end of the billet receiving section I and the billet inspecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com