Encapsulation hot press

A hot press and potting technology, applied in packaging sealing/fastening, biocides, plant growth regulators, etc., can solve the problems of low production efficiency, high cost, and inability to mass-produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

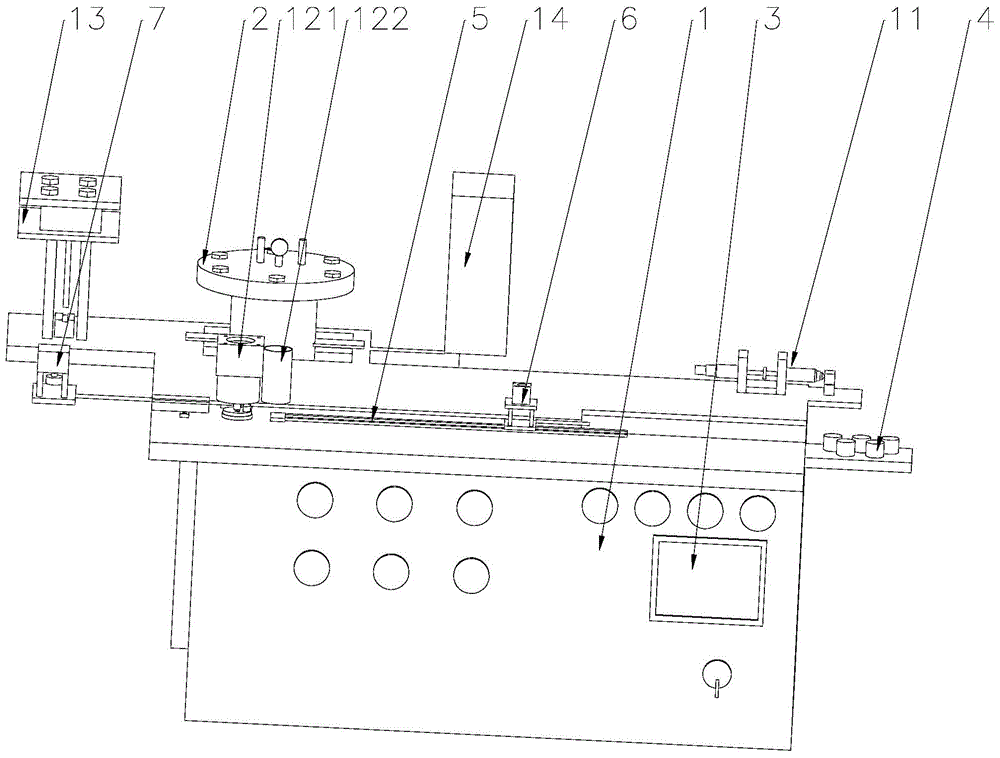

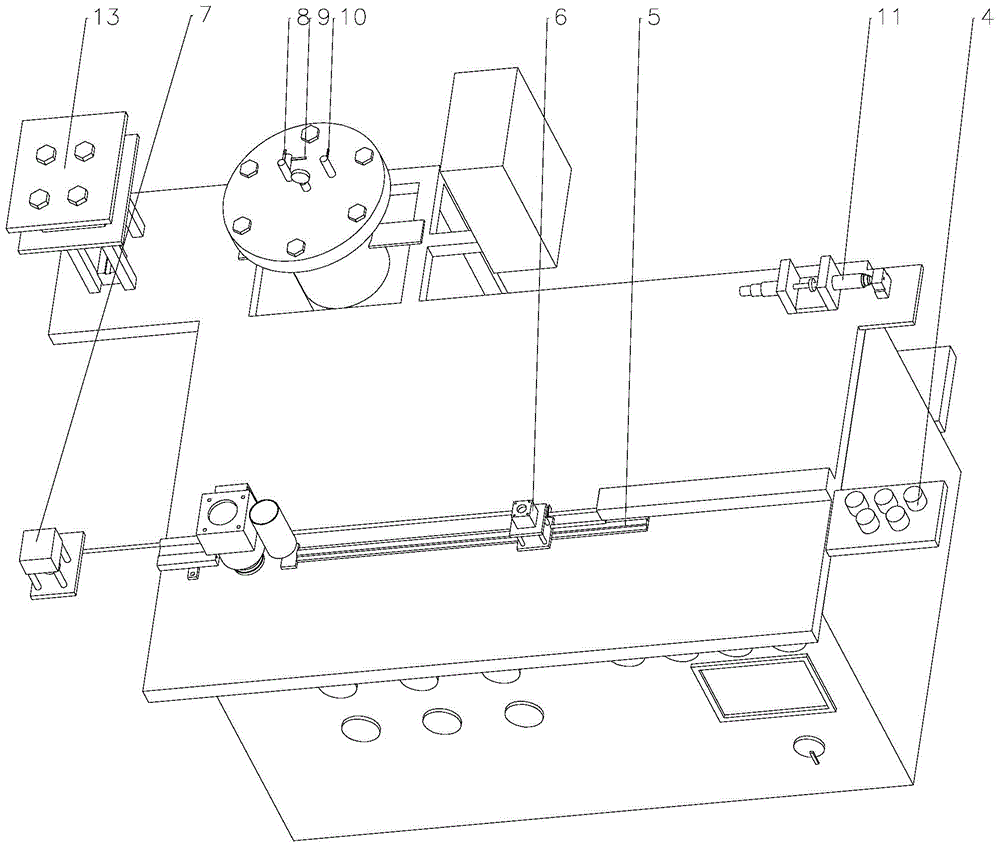

[0028] Such as figure 1 with figure 2 As shown, a potting and sealing hot press includes a frame 1 and a frame set on the frame 1

[0029] The potting device 11, the potting device 11 is used for attracting agent filling to the fan direction silk carrier,

[0030] The hot-pressing sealing device is used to heat and seal the filled Mixiang silk carrier,

[0031] The cutting device 13 is used to cut the fan-directed silk carrier after the sealing is completed,

[0032] The control device 14 is respectively connected with the potting device 11, the hot pressure sealing device and the shearing device 13. The control device 14 realizes the action control of the potting device 11, the hot pressure sealing device and the shearing device 13. The potting device 11 includes The material tank 2 containing the attractant, the bottom of the material tank 2 is connected to the potting device 11 through a pipe through a provided discharge port, and the potting device 11 sends the attractant into t...

Embodiment 2

[0037] Such as figure 1 with figure 2 As shown, it is basically the same as Embodiment 1, except that: after the potting device 11 completes the attractant filling of the Mixiang silk carrier, the control device 14 controls the Mixiang silk carrier to automatically enter the hot-pressing sealing device to realize heating and sealing. Then the fan-directed silk carrier is controlled to automatically enter the shearing device 13 to realize shearing, which has a higher degree of automation and greatly improves production efficiency.

Embodiment 3

[0039] Such as figure 1 with figure 2 As shown, it is basically the same as embodiment 1, except that: the material tank 2 is equipped with a vacuum degassing stirring motor to realize vacuum degassing; it is also provided with a straightening mechanism 4 for straightening the phantom silk carrier. The straight mechanism 4 is arranged before the heat-press sealing device heats and seals the fan-directed silk carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com