A new type of solid wood board and its processing method

A processing method and solid wood technology, which is applied in the processing of new solid wood panels, wood processing, and the field of new solid wood panels, can solve the problems of poor heat insulation and sound insulation, low wood utilization rate, and low production efficiency, and achieve good sound insulation effects. Small waste of leftover materials and low transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following will be further described with reference to the accompanying drawings and in conjunction with specific embodiments, so that those skilled in the art can implement it by referring to the text of the description, and the scope of protection is not limited by the embodiments of the technical solution.

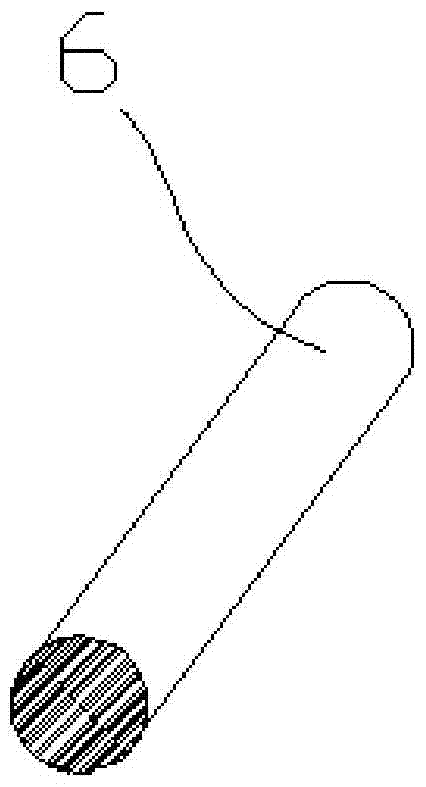

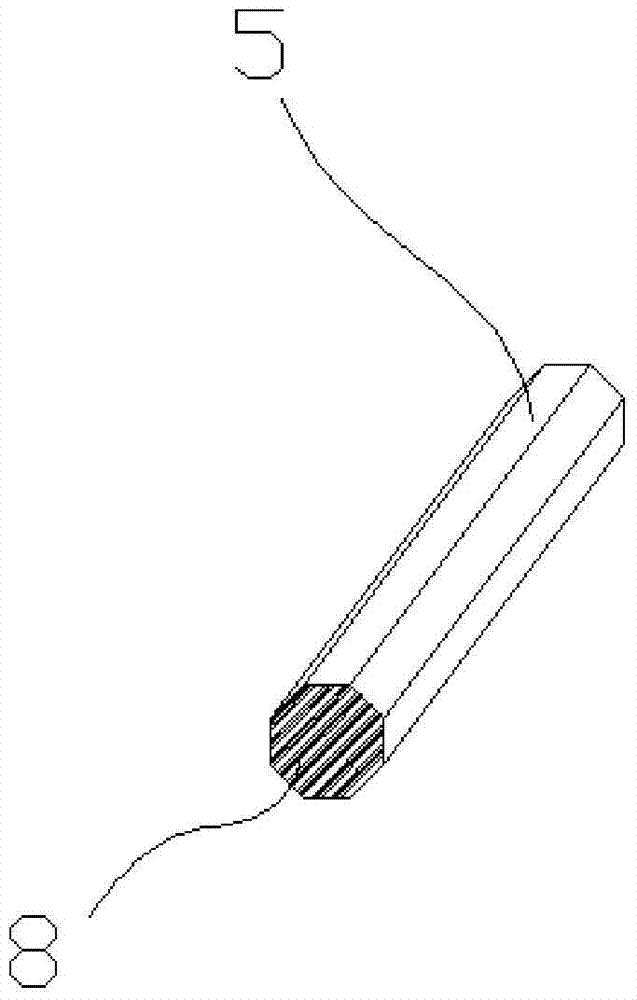

[0043] The preferred embodiment of the present invention is as follows Figure 1 to Figure 10 As shown, a new type of solid wood board includes an upper board body 2 and a lower board body 3 that are uniformly thinned by a board body 1, wherein the board body 1 is made of a plurality of equal lengths and the same length of the reference plane 8. The side-shaped prisms 4 are arranged side by side and joined together to form; the bottom surfaces of the upper plate body 2 and the lower plate body 3 are hexagonal in shape, wherein the upper plate body 2 as the bottom layer and the lower plate body 3 as the top layer Neatly spliced up and down and pressed togethe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com