Calculation method of variable blank holder force for forming and drawing die using the method

A technology of variable blank holder force and calculation method, applied in the field of stamping dies, can solve the problems of high cost, inconvenient installation, unfavorable promotion and use, etc., and achieve the effect of improving formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

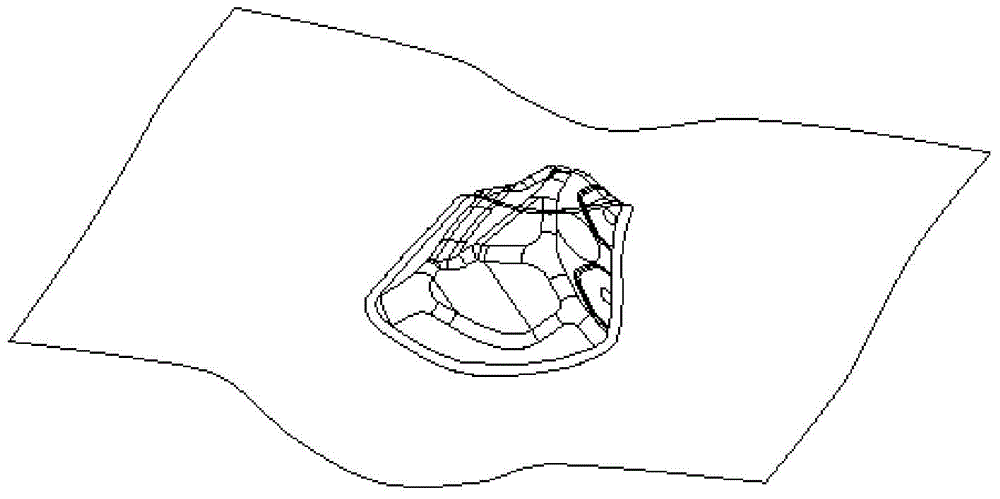

[0026] The following will be combined with Figure 1-9 The technical solution of the present invention is described in detail.

[0027] Such as Figure 5 As shown, the present invention provides a kind of variable blank-holding force calculation method that is beneficial to formability, and it specifically comprises the following steps:

[0028] Step 1. Establish the supplementary surface of the initial drawing process of the part;

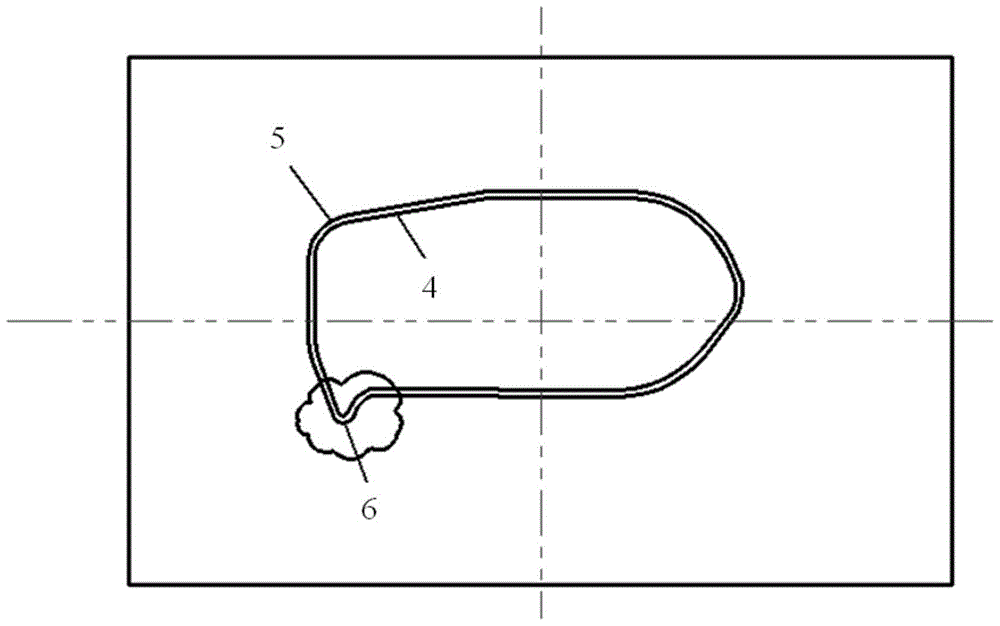

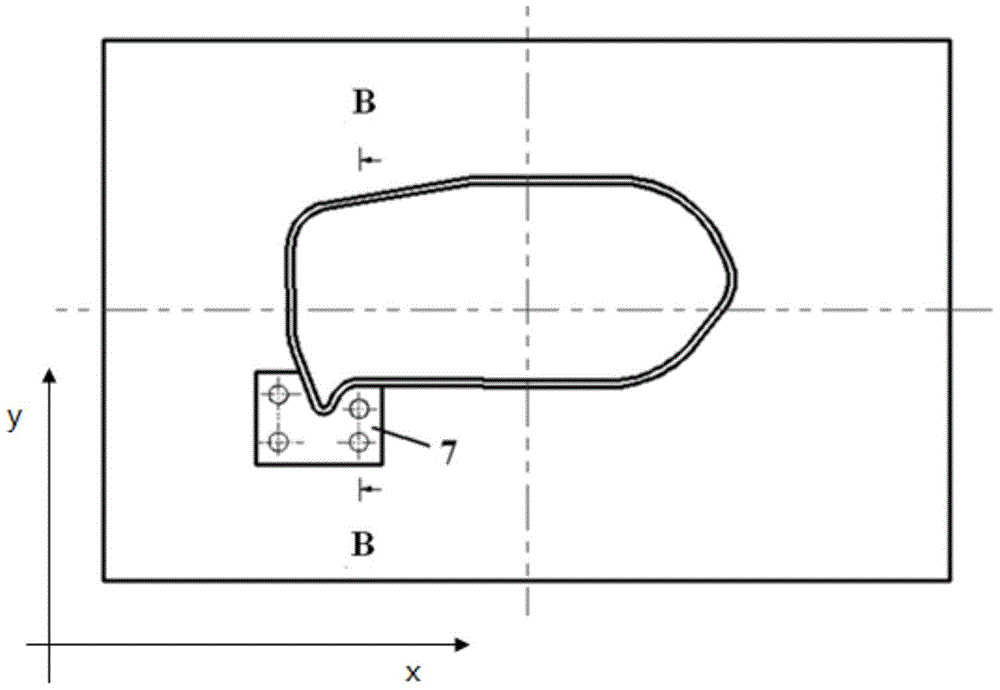

[0029] Such as figure 1 As shown, the drawing surface is also called the binder surface, in order to prevent deformation of the blank. In many parts, such as the engine cover, the drawing surface is all process supplementary surface. In the drawing die design process, the first step is to design a reasonable supplementary surface for the drawing process, which mainly includes the design of the drawing surface and the trimming surface. In the drawing forming process of automobile panels, the design of the supplementary surface of the drawing pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com