A kind of electromagnetic mems vibration energy harvester and preparation method thereof

A vibration energy collection, electromagnetic technology, applied in the direction of electric components, motor generators, electromechanical devices, etc., can solve the problems of low energy collection efficiency, limited vibration energy, limited energy collection efficiency, etc., to achieve high energy collection efficiency, Small size, good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

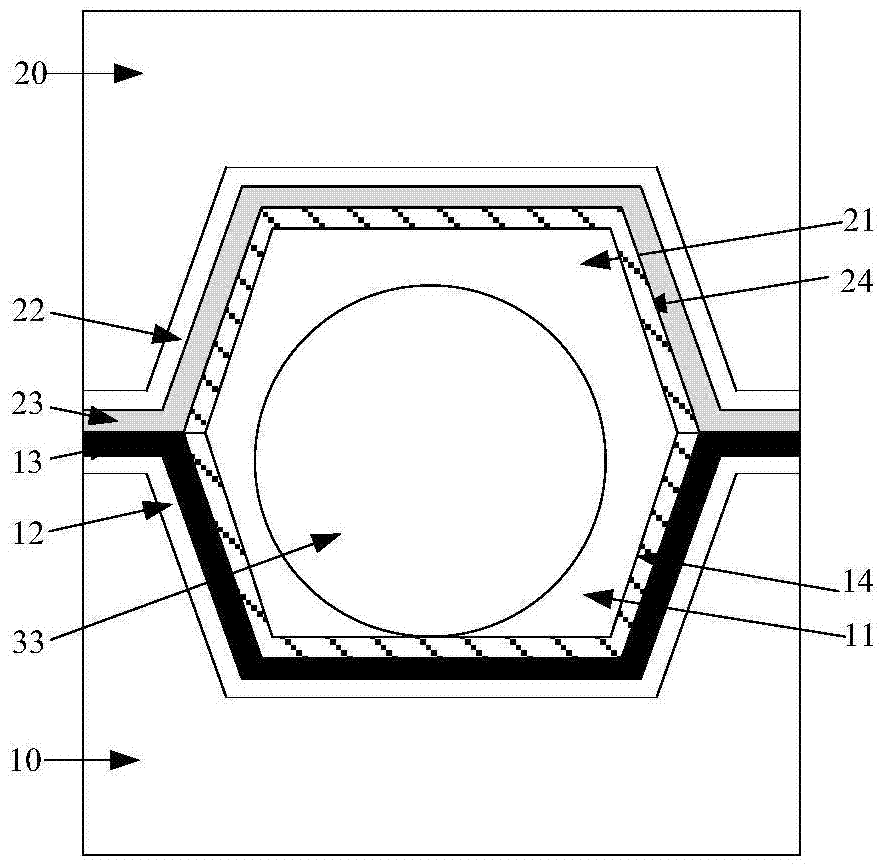

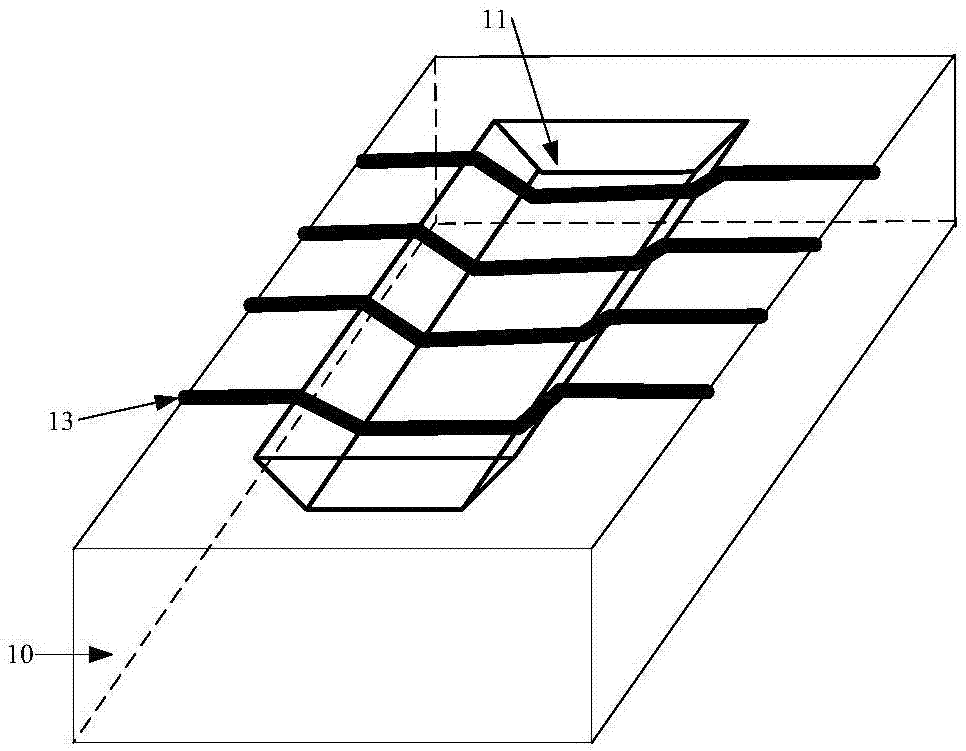

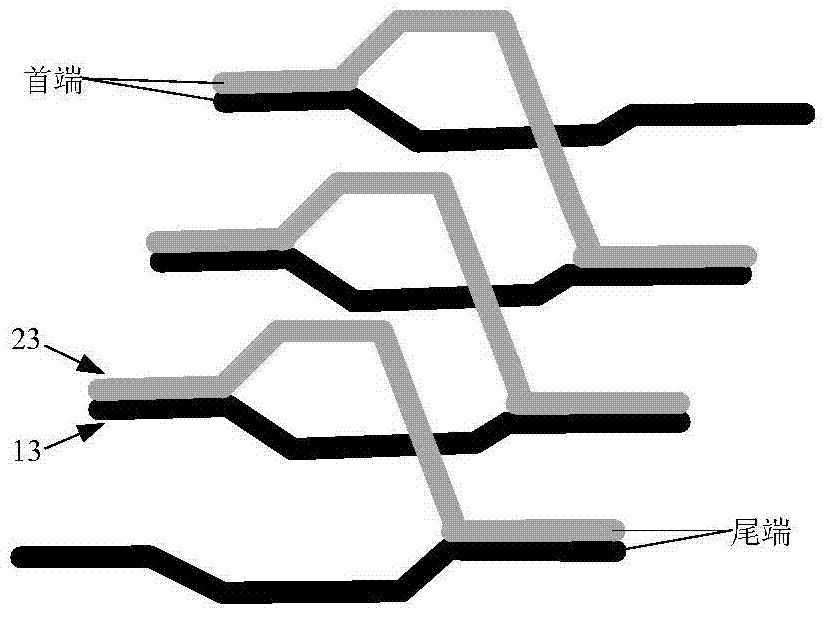

[0030] A preparation method of an electromagnetic MEMS vibration energy harvester, comprising the steps of:

[0031] (1), select N-type (100) silicon as the first substrate 10, and grow SiO with a thickness of 1000 nm on the upper surface of the first substrate 10 by wet oxygen thermal oxidation 2 , wherein the shape of the first substrate 10 is a long rectangle.

[0032] (2), with the SiO prepared by step (1) 2 Make a mask, use TMAH (Tetramethyl ammoniumhydroxide, tetramethylammonium hydroxide) reagent to carry out anisotropic wet etching on the first substrate 10, the etching depth is 50-200 μm, after etching, the first substrate 10 A first groove 11 is formed in the middle of the upper surface.

[0033] (3), use HF (hydrofluoric acid) solution to remove the SiO on the surface of the first substrate 10 2 , and re-grow SiO with a thickness of 100-1000 nm on the surface of the first substrate 10 and the bottom and peripheral regions of the first groove 11 by wet oxygen ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com