Rolling fingerprint acquisition method based on thermochromic principle

A temperature-induced discoloration and fingerprint technology, which is applied in the direction of instruments, character and pattern recognition, computer components, etc., can solve the problems of stagnant fingerprint management work, blurred fingerprints, and unsatisfactory results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

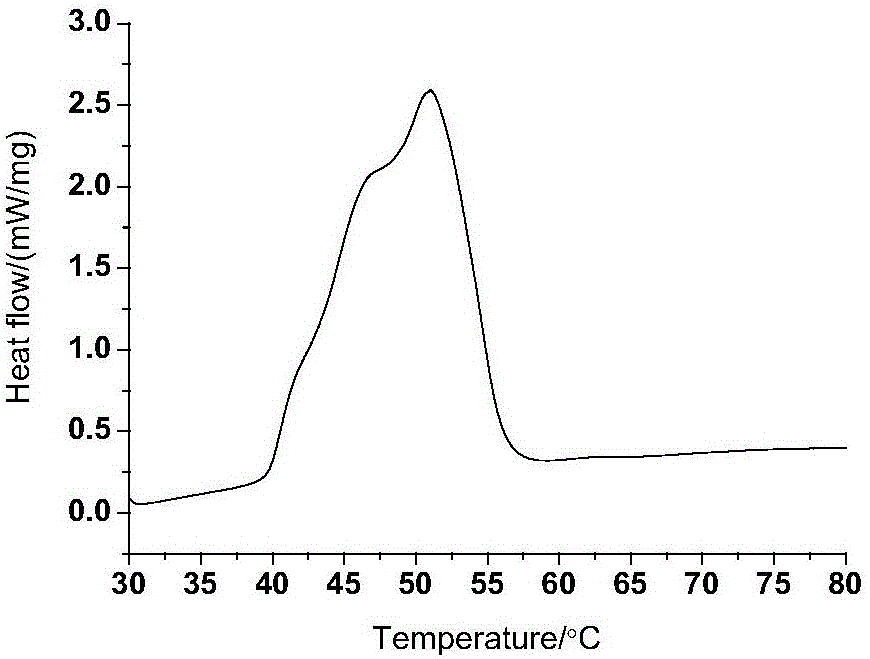

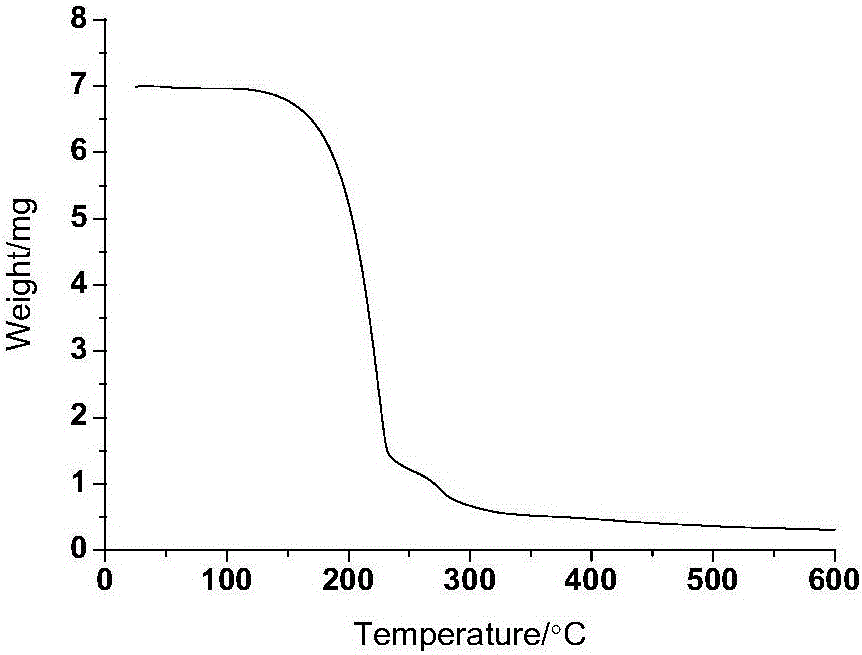

[0020] 1) Using crystal violet lactone compound as the capsule core material and urea-formaldehyde resin as the capsule wall material, a thermochromic microcapsule was prepared by in-situ polymerization (the scanning electron microscope image of the thermochromic microcapsule is shown in figure 1 , the differential scanning calorimetry diagram is shown in figure 2 , see the thermogravimetric analysis diagram image 3 ).

[0021] 2) The dispersion liquid formed by mixing the prepared thermochromic microcapsules with 0.7% aqueous solution of sodium carboxymethyl cellulose is used as a drop coating solution, and the drip coating method is used to drip and flow on the surface of a glass slide to obtain a thermochromic film ( The UV reflection diagram of the thermochromic film is shown in Figure 4 ).

[0022] 3) Use a heater to adjust the surface temperature of the film, and place the collected person's finger on the thermochromic film to roll (see the influence of film surfac...

example 1

[0027] By adjusting the surface temperature of the film to 52°C, a clear fingerprint image can be obtained by rolling a finger on the thermochromic film. The obtained fingerprint image is relatively clear, and the secondary information including the fingerprint itself can also be seen with the naked eye (see Figure 5 B). After the fingerprint image is obtained, the slide is cooled until the fingerprint disappears and the thermochromic film returns to its previous dark blue color.

example 2

[0029] By adjusting the surface temperature of the film to 54°C, the subject’s finger rolled on the thermochromic film, took it out and took a picture. Because the surface temperature of the film is too high, the temperature of the place on the thermochromic film in contact with the finger cannot be completely lowered below the discoloration point, and the discoloration reaction is not complete, resulting in an incomplete fingerprint image, and even almost no fingerprint information ( See Figure 5 A).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com