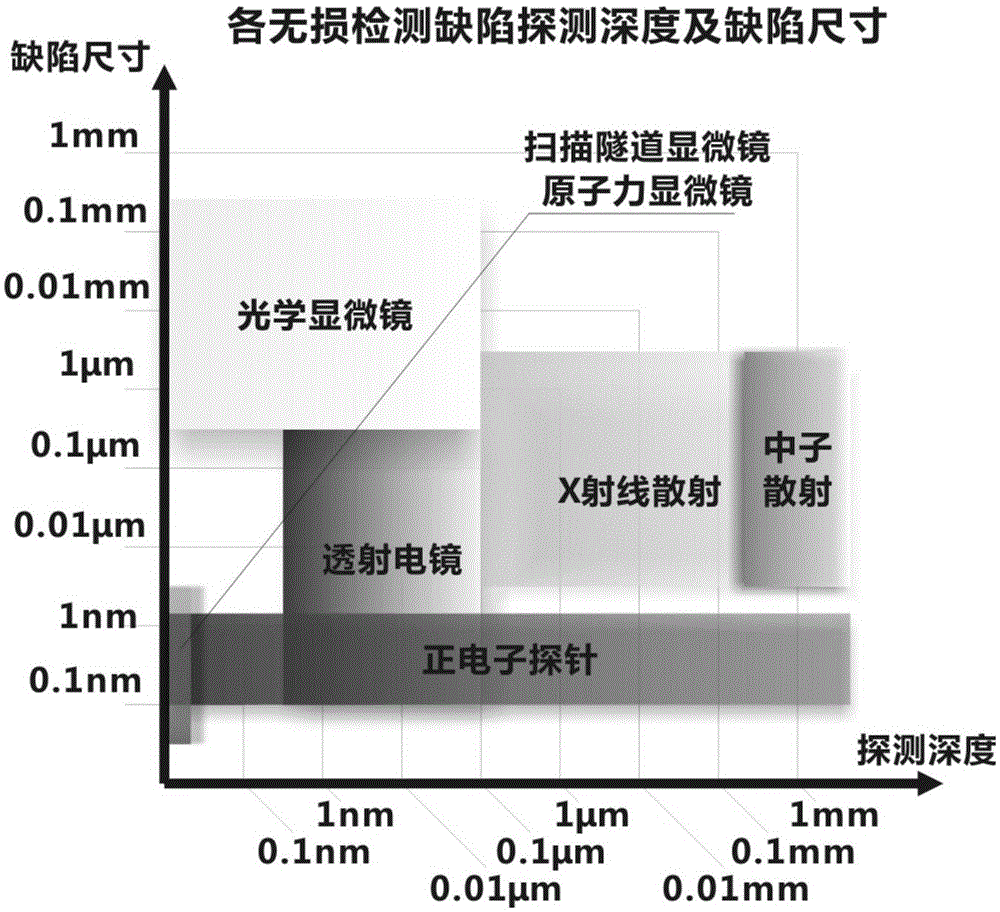

Nondestructive testing system and method for positioning chamber inner wall defect through positron probe

A technology of non-destructive testing and detection methods, applied in measurement devices, material analysis using wave/particle radiation, instruments, etc., to achieve the effect of improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

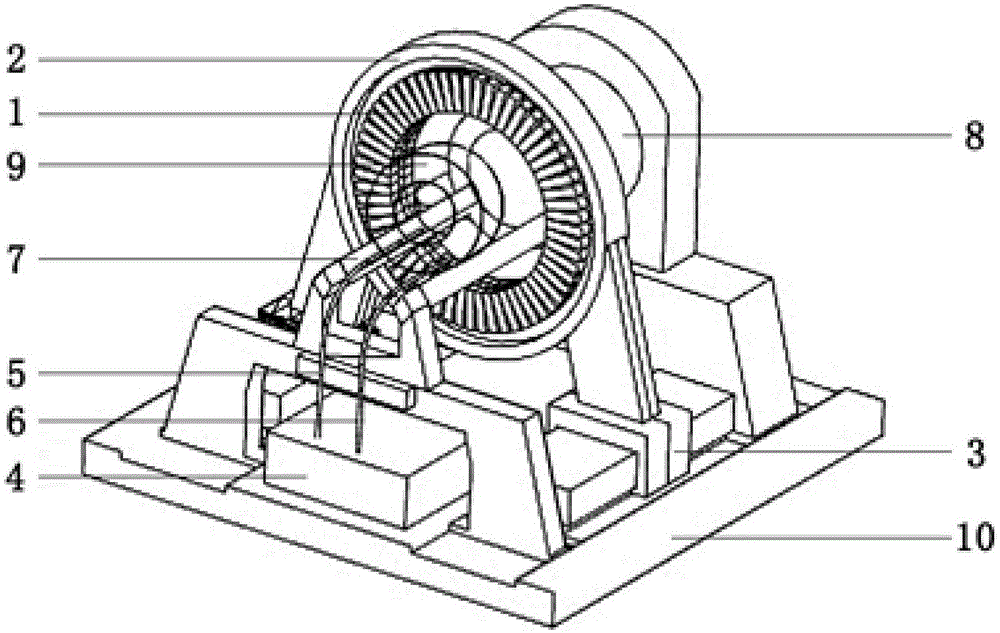

[0031] The non-destructive testing system for locating the inner wall defect of the cavity by the positron probe of the present invention can accurately locate the structural defect of the complex inner cavity of the part in three dimensions. The objects measured by the non-destructive testing system of the present invention are as follows: 1. The inner cavity of the "beer bottle-shaped" parts with liquid storage space, such as piston cylinders, valve body accumulators, etc.; 2. The inner wall of the stepped pipeline structure, For example, integrated valve pipeline, servo electro-hydraulic control valve pipeline and flow diversion on the inner wall of capillary, etc.; 3. Closed parts assembly with fixed liquid input and output ports, such as internal combustion engine fuel circuit, gearbox hydraulic torque converter system, aviation turbine engine combustion circuit, aviation hydraulic system electro-hydraulic servo integrated unit, etc.

[0032] In the present invention, the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com