Low-coupling axial and radial combined loading device for rolling bearing and loading method

A rolling bearing and compound loading technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of large lateral stiffness of the loading device, incomplete loading of the load, inaccurate loading of the load, etc., to avoid the influence of the test load, low axial and lateral stiffness, Eliminate the effects of mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

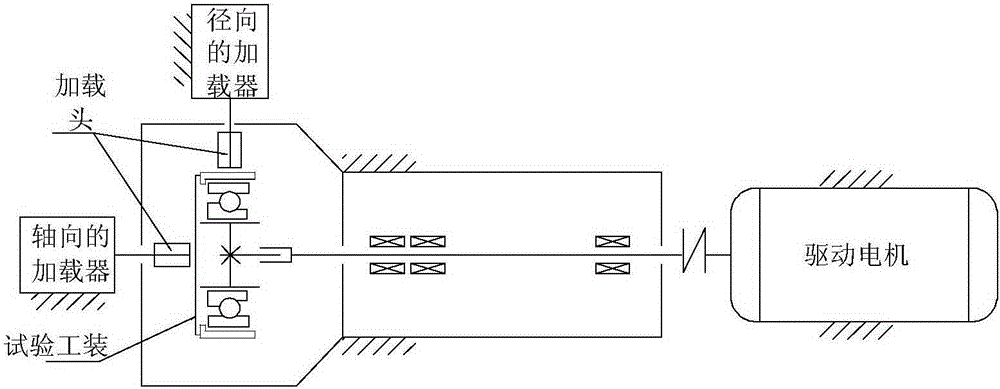

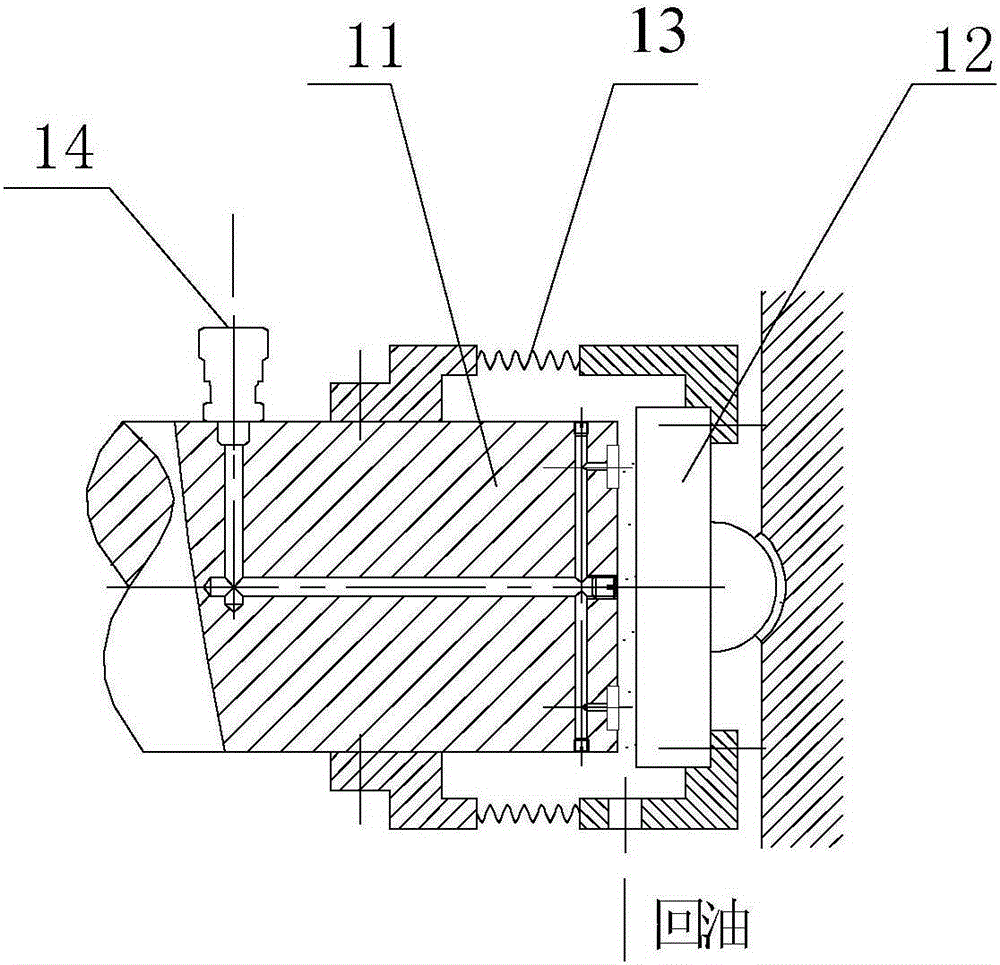

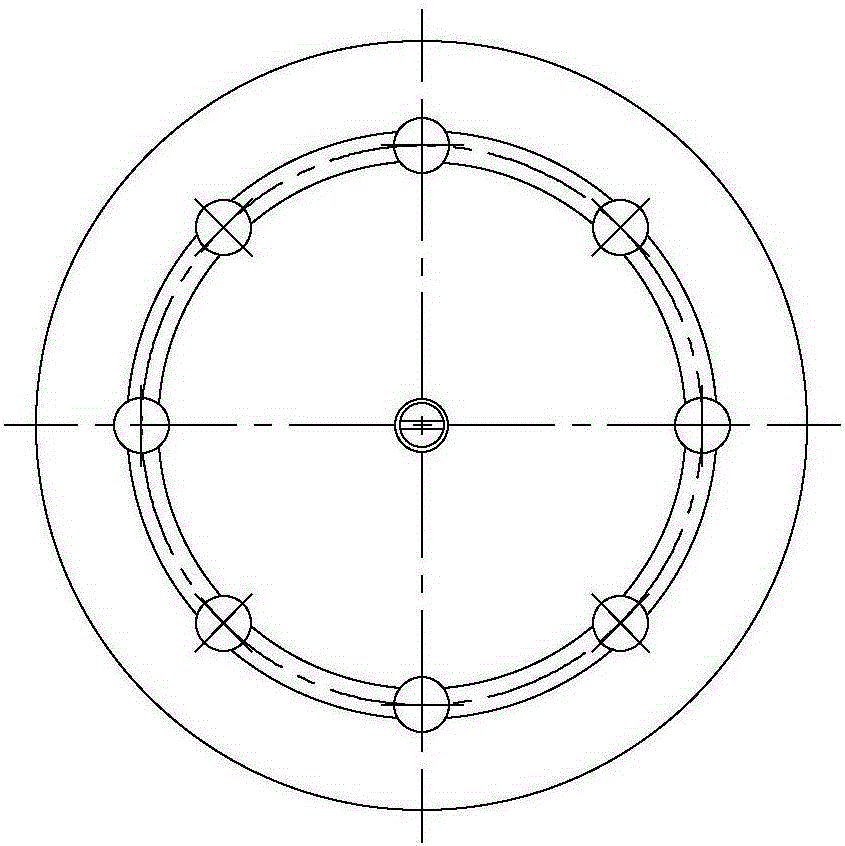

[0027] Specific implementation mode one: refer to Figure 2 to Figure 4 Specifically explain this embodiment, the low-coupling axial and radial compound loading device for rolling bearings described in this embodiment, which includes a hydraulic system and two loading heads,

[0028] The hydraulic system connects two loading heads at the same time. The hydraulic system provides pressure oil for the loading head. One loading head is used to install between the radial loader and the rolling bearing test fixture, and the other loading head is used to install the axial loader. and rolling bearing test fixture,

[0029] The hydraulic system includes small oil tank 1, cooler 2, No. 1 oil filter 3, hydraulic pump 4, No. 2 oil filter 6, No. 1 overflow valve 7, No. 2 overflow valve 17, No. 1 throttle valve 8, No. two throttle valve 18, No. one check valve 9 and No. two check valve 19,

[0030] The small oil tank 1 is located at the lower part of the oil return port of the rolling bea...

specific Embodiment approach 2

[0044] Specific embodiment 2: This embodiment is a further description of the low-coupling axial and radial composite loading device for rolling bearings described in specific embodiment 1. In this embodiment, the hydraulic system also includes No. 1 pressure gauge 5, No. 2 pressure gauge Pressure gauge 10 and No. 3 pressure gauge 20,

[0045] The No. 1 pressure gauge 5 is set on the oil outlet pipeline of the hydraulic pump 4, the No. 2 pressure gauge 10 is set on the oil inlet pipeline of 14, and the No. 3 pressure gauge 20 is set on the pressure oil inlet 14-1 of the other loading head. on the oil inlet line.

specific Embodiment approach 3

[0046] Specific embodiment three: This embodiment is to further explain the low-coupling axial and radial composite loading device of the rolling bearing described in specific embodiment one. Lubricant in between.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com