Gas pipeline safety leak prevention control method

A control method and gas pipe technology, applied in the field of safety valves, can solve problems such as gas explosion, carbon monoxide poisoning, gas leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

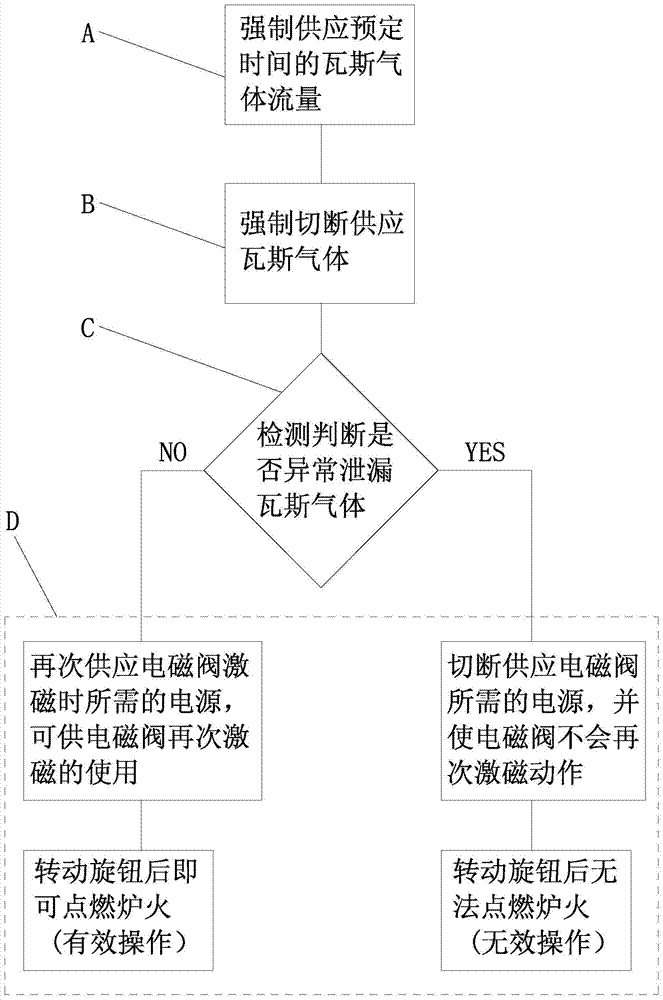

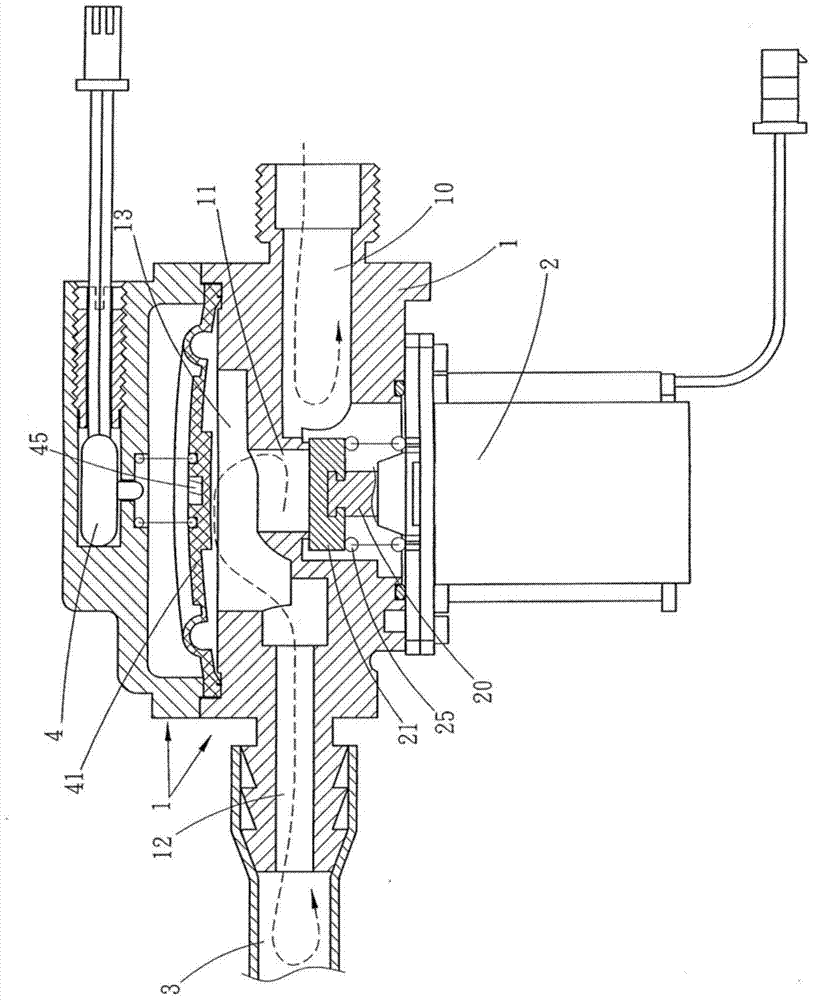

[0017] Attached below figure 1 with figure 2 The present invention is described further:

[0018] Such as figure 1 with figure 2 A kind of gas pipeline 3 safety leak-proof control method shown, its method is as follows:

[0019] (A), mandatory supply of gas flow for a predetermined time; before igniting the fire, the electromagnetic valve 2 must be forced to start with a control element (not shown in the figure) to generate an excitation action for a predetermined time, so that it is already located in the electromagnetic valve 2 The piston plate 21 on the shaft rod 20 can be far away from the intake passage 10 of the safety valve 1 (that is, it is in an open state), and allows the gas to flow into the safety valve 1 through the intake passage 10 of the safety valve 1 The air inlet channel 11, the air chamber 13, the air outlet channel 12 and the inside of the pipeline 3. At the same time, the gas that has been located in the air chamber 13 can push the membrane member 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com