A kind of plant fiber and pha composite oil-absorbing paper and preparation method thereof

A plant fiber and oil-absorbing paper technology, which is applied in natural cellulose pulp/paper, special paper, textiles and papermaking, etc., can solve the problems of sticking skin, difficult natural degradation of products, environmental pollution, etc., and achieve soft touch and excellent compatibility Sexuality, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) adding water to the cotton fiber to decompose and disperse it to obtain a decomposed cotton fiber suspension, and to control the mass concentration of the cotton fiber to be 1%;

[0036] (2) successively add the cationic starch that is equivalent to cotton fiber quality 0.75%, the cationic polyacrylamide of 0.04%, the bentonite of 0.5%, the talcum powder of 0.5% and the modified PHA of 10% in the deflated cotton fiber suspension, stir Mix well, then pour it into a Buchner funnel with filter paper for filtration, move the formed wet sheet to two stacks of filter paper to remove excess free water, then replace the wet filter paper, put in a press for pressing dry. The weight of copying is 30g / m 2 . Obtain plant fiber and PHA composite oil-absorbing paper.

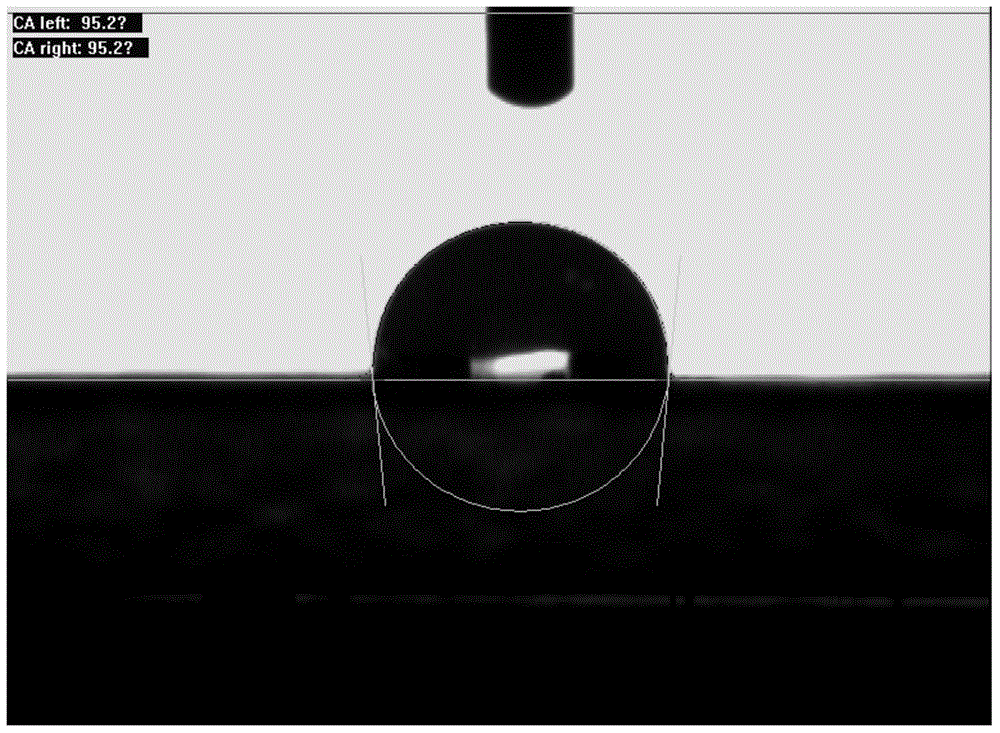

[0037] The oil-absorbing paper that present embodiment obtains carries out water contact angle test, and the result is as follows figure 1 shown by figure 1 It can be concluded that the contact angle of water ...

Embodiment 2

[0039] (1) adding water to the cotton fiber to decompose and disperse it to obtain a decomposed cotton fiber suspension, and to control the mass concentration of the cotton fiber to be 1%;

[0040] (2) successively add the cationic starch that is equivalent to cotton fiber quality 0.75%, the cationic polyacrylamide of 0.04%, the bentonite of 0.5%, the talcum powder of 0.5% and the modified PHA of 20% in the deflated cotton fiber suspension, stir Mix well, then pour it into a Buchner funnel with filter paper for filtration, move the formed wet sheet to two stacks of filter paper to remove excess free water, then replace the wet filter paper, put in a press for pressing dry. The weight of copying is 30g / m 2 . Obtain plant fiber and PHA composite oil-absorbing paper.

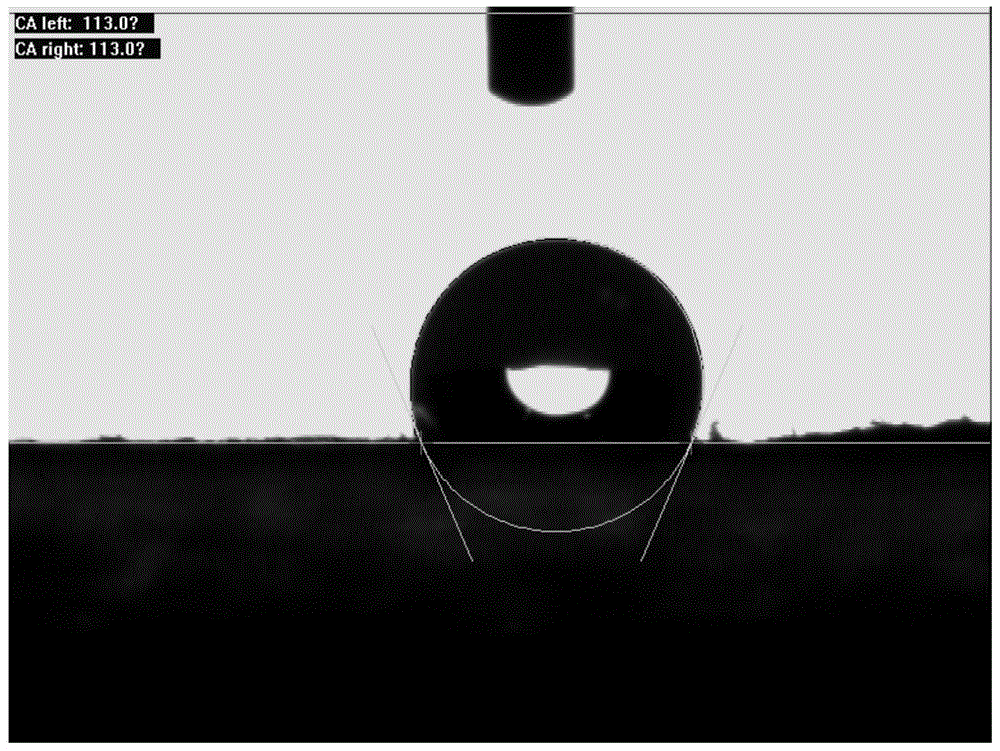

[0041] The oil-absorbing paper that present embodiment obtains carries out water contact angle test, and the result is as follows figure 2 shown by figure 2 It can be concluded that the contact angle of wate...

Embodiment 3

[0043] (1) adding water to the cotton fiber to decompose and disperse it to obtain a decomposed cotton fiber suspension, and to control the mass concentration of the cotton fiber to be 1%;

[0044] (2) add cationic starch, 0.04% cationic polyacrylamide, 0.5% bentonite, 0.5% talcum powder and 30% modified PHA equivalent to cotton fiber quality 0.75% in the fluffed cotton fiber suspension successively, stir Mix well, then pour it into a Buchner funnel with filter paper for filtration, move the formed wet sheet to two stacks of filter paper to remove excess free water, then replace the wet filter paper, put in a press for pressing dry. The weight of copying is 30g / m 2 . Obtain plant fiber and PHA composite oil-absorbing paper.

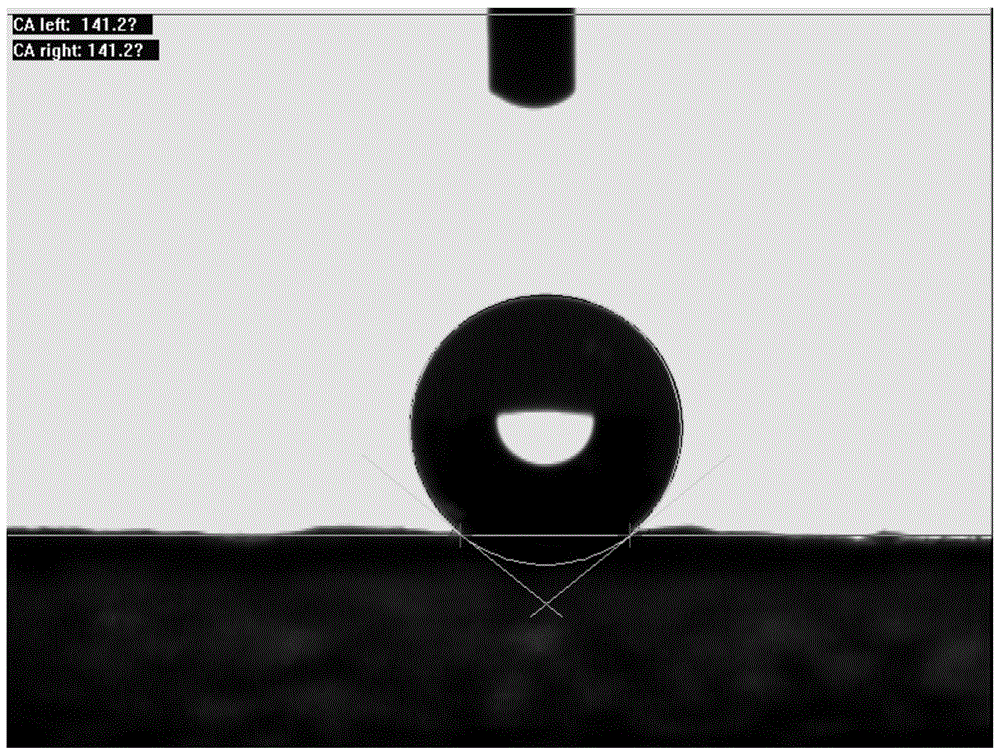

[0045] The oil-absorbing paper that present embodiment obtains carries out water contact angle test, and the result is as follows image 3 shown by image 3 It can be concluded that the contact angle of water is 141.2°. The oil absorption test resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com