A rapid coal pyrolysis reaction device and a coal pyrolysis reaction system based on the device

A pyrolysis reaction and reaction system technology, applied in the direction of direct heating dry distillation, special form dry distillation, petroleum industry, etc., can solve the problems of slow heat and mass transfer of cold and hot materials, uneven distribution of internal temperature field, slow heating rate, etc. Achieve the effect of rapid pyrolysis, high utilization rate of raw materials, and rapid heat and mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

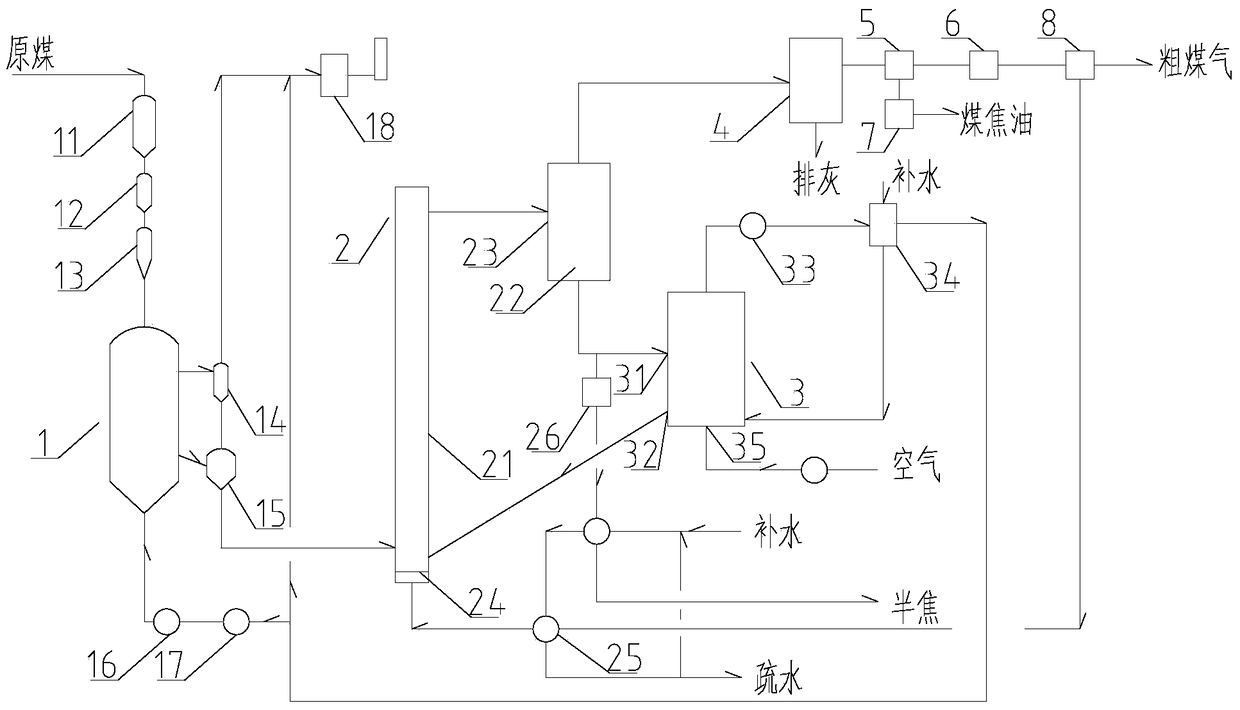

[0032] This embodiment provides a coal pyrolysis reaction system, the structure of which is as follows figure 1 As shown, the connected arrangement includes: a raw coal preheater 1, a coal rapid pyrolysis reaction device 2, a burner 3, a separation dust removal device, and a spray purification unit 6.

[0033] The raw coal preheater 1 is used for preheating raw coal. The top of the raw coal preheater 1 is provided with a raw coal input port, the lower portion is provided with a coal outlet, and the upper portion is provided with a flue gas output port; Upstream of the preheater 1, connected to the raw coal input port of the raw coal preheater 1, a crushing chamber 11, a sorting chamber 12, and a particle size adjusting chamber 13 are arranged in order to screen the raw coal before preheating; Downstream of 1, a dry coal bunker 15 is arranged in connection with the coal outlet of the raw coal preheater 1, and a separator 14 is arranged in connection with the flue gas outlet of ...

Embodiment 2

[0046] This embodiment provides a coal pyrolysis reaction system, the structure of which is as follows figure 1 As mentioned above, the connected arrangement includes: a raw coal preheater 1, a coal rapid pyrolysis reaction device 2, a burner 3, a separation and dust removal device, and a spray purification unit 6.

[0047] The raw coal preheater 1 is used for preheating raw coal. The raw coal preheater 1 is provided with a raw coal input port at the top, a high temperature flue gas input port at the bottom, a coal outlet at the lower portion, and a coal outlet at the upper portion. The flue gas output port; upstream of the raw coal preheater 1, connected to the raw coal input port of the raw coal preheater 1 in sequence, there are a crushing chamber 11, a sorting chamber 12, and a particle size adjustment chamber 13, which are used for preheating. The raw coal is screened; at the downstream of the raw coal preheater 1, a dry coal bunker 15 is connected to the coal outlet of t...

Embodiment 3

[0060] This embodiment provides a coal pyrolysis reaction system, the structure of which includes: a raw coal preheater 1, a rapid coal pyrolysis reaction device 2, a separation and dust removal device, and a spray purification unit.

[0061] The coal rapid pyrolysis reaction device 2 is provided with a straight pipe pyrolysis section 21 and a gas-solid separation chamber 23 in sequence from bottom to top; the bottom of the straight pipe pyrolysis section 21 is provided with a crude gas inlet, and the lower part is provided with a coal inlet and a high temperature The carrier inlet is provided with a discharge port at the top; the length-to-diameter ratio of the straight pipe pyrolysis section 21 is 40:1;

[0062] The gas-solid separation chamber 23 is located above the straight pipe pyrolysis section 21 and is connected to the upper end of the straight pipe pyrolysis section 21; the top end of the straight pipe pyrolysis section 21 extends to the gas-solid Set in the separati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com