Phase change cold-accumulation material and preparation method thereof

A phase-change cold storage and nano-technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of reducing the phase transition temperature of sodium sulfate decahydrate, the hysteresis effect of phase transition temperature is large, and the long-term use cannot be achieved. The effect of repeated cycle decay is low, phase change temperature hysteresis is small, and production is easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

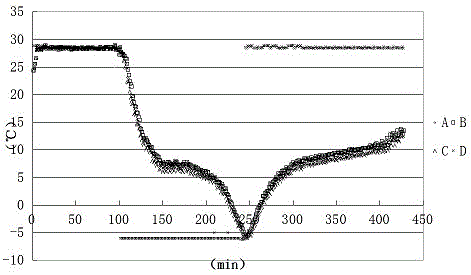

[0028] Add 600kg of sodium sulfate decahydrate, 150kg of sodium bromide, 50kg of ammonium chloride, 15kg of borax, and 20kg of boric acid to the heating tank. After gradually melting, stir them evenly until all are melted. Add slowly at a stirring speed of 4000rpm 30kg of alumina, 20kg of nano-magnesium silicate, 40kg of nano-silica, supplement with 75kg of deionized water, stir evenly, keep at 40°C for one hour, and cool to room temperature to obtain a uniform paste, which is the phase change cold storage Material, the latent heat of phase change is 215KJ / kg, the temperature range of cooling phase change is 8.2~9.1℃, and the temperature range of heating phase change is 9.3~10.7℃.

Embodiment 2

[0030] Add 500kg of sodium sulfate decahydrate, 150kg of sodium bromide, 40kg of ammonium chloride, 10kg of borax, and 15kg of boric acid to the heating tank successively. After gradually melting, stir them evenly until all are melted. Add slowly at a stirring speed of 3000rpm 30kg of alumina, 20kg of nano-magnesium silicate, 40kg of nano-silica, supplement with 195kg of ionized water, stir evenly, keep at 40°C for one hour, cool to room temperature naturally to obtain a uniform paste, that is, the phase change cold storage material , The latent heat of phase change is 222KJ / kg, the temperature range of cooling phase change is 7.2~8.3℃, and the temperature range of heating phase change is 8.2~10.5℃.

Embodiment 3

[0032] Add 550kg of sodium sulfate decahydrate, 130kg of sodium bromide, 20kg of ammonium chloride, 30kg of borax, and 10kg of boric acid to the heating tank successively, and control the temperature of the mixture at about 60~70℃, stir until it is completely melted, at the stirring speed of Add 30kg alumina, 20kg nano-magnesium lithium silicate, 40kg nano-silica, add 170kg deionized water at 3500rpm and slowly add 170kg deionized water, stir well, keep it at 40℃ for one hour, then cool to room temperature to obtain a uniform paste, namely The phase change cold storage material is obtained, the latent heat of phase change is 201KJ / kg, the temperature range of cooling phase change is 6.9-8.1°C, and the range of temperature rising phase change is 8.0-9.8°C.

[0033] Observed at room temperature, the phase change cold storage materials of the above examples 1 to 3 are in a paste form, the phase change temperature is about 8~11℃, which meets the requirements of air conditioning system...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com