A kind of salt spray resistant SBS adhesive and preparation method thereof

An adhesive and salt spray-resistant technology, applied in the direction of adhesives, adhesive types, rosin adhesives, etc., can solve problems such as poor environmental protection, limited use range of SBS adhesives, and volatile organic solvents, etc., to achieve good environmental protection and excellent Salt mist resistance, less irritating odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Control the temperature in the reactor at 10-25°C, add 45 parts of solvent (including 15 parts of 120# solvent oil, 10 parts of dimethyl carbonate and 20 parts of petroleum ether) into the reactor, and then slowly add 15 parts of thermoplastic Styrene-butadiene rubber (including 10 parts of YH-792 and 5 parts of YH-802SBS rubber); control the temperature in the reactor to 10-25°C, keep the reactor closed and continue to stir, and then add the thermoplastic styrene-butadiene rubber after it dissolves 25 parts of tackifying resin (including 8 parts of C9 petroleum resin, 10 parts of hydrogenated rosin glyceride and 7 parts of terpene resin); keep the same temperature as before and stir in airtight, after the tackifying resin is completely dissolved, add 5 parts of anti-salt Fog aid, 5 parts of silane coupling agent, 5 parts of anti-aging agent, stir evenly, pour the adhesive out of the reaction kettle, and filter to obtain the salt spray-resistant SBS adhesive of this embo...

Embodiment 2

[0028] Compared with Example 1, Example 2 only has a change in the weight ratio of each component, and the other contents are exactly the same. For the sake of simplicity, the same contents will not be repeated here. The weight ratio of each component is as follows:

[0029] 25 parts of thermoplastic styrene-butadiene rubber (including 15 parts of YH-792 SBS rubber and 10 parts of YH-802SBS rubber), 10 parts of tackifying resin (including 6 parts of C9 petroleum resin and 4 parts of hydrogenated rosin glyceride), salt spray resistance auxiliary 0.1 part of agent, 0.1 part of silane coupling agent, 0.1 part of anti-aging agent, 60 parts of solvent (including 15 parts of ethyl acetate, 10 parts of dimethyl carbonate, 8 parts of kg butyl acetate, 7 parts of petroleum ether, 20 parts of 120# Solvent oil).

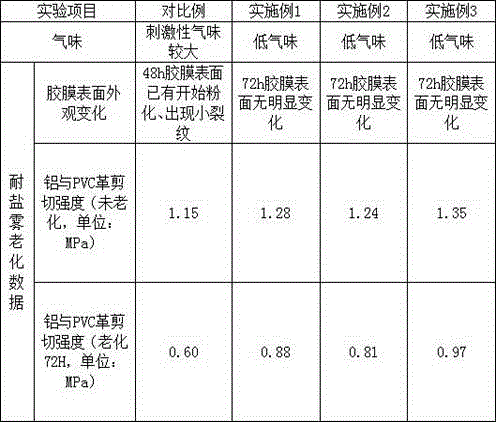

[0030] Thereafter, the salt spray-resistant SBS adhesive obtained in Example 2 was also made into a shear sample (adhesive material is 1060 aluminum sheet and PVC floor leathe...

Embodiment 3

[0032] Embodiment 3 compares with embodiment 1 and 2, only the weight proportion of each component changes, and other contents are identical, and the weight proportion of each component of embodiment 3 is as follows:

[0033]17 parts of thermoplastic styrene-butadiene rubber (including 10 parts of YH-792 SBS rubber and 7 parts of YH-802SBS rubber), 25 parts of tackifying resin (including 8 parts of C9 petroleum resin, 10 parts of hydrogenated rosin glyceride, 7 parts of terpene resin ), 4 parts of salt spray additive, 3 parts of silane coupling agent, 2.5 parts of anti-aging agent, 48.5 parts of solvent (including 15 parts of ethyl acetate, 10 parts of dimethyl carbonate, 4 parts of butyl acetate, 7 parts of petroleum ether , 12.5 parts of 120# solvent oil).

[0034] Thereafter, the same salt spray-resistant SBS adhesive obtained in Example 3 was also made into a shear sample (adhesive material is 1060 aluminum sheet and PVC floor leather) and cured into an adhesive film, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com