Elastomer coating hollow micro-spheres, method for preparing same and application of elastomer coating hollow micro-spheres

A hollow microsphere and preparation process technology, applied in the directions of fibrous filler, dyed polymer organic compound treatment, dyed organic silicon compound treatment, etc. Good performance, environmental protection, and the effect of eliminating the use of volatile solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

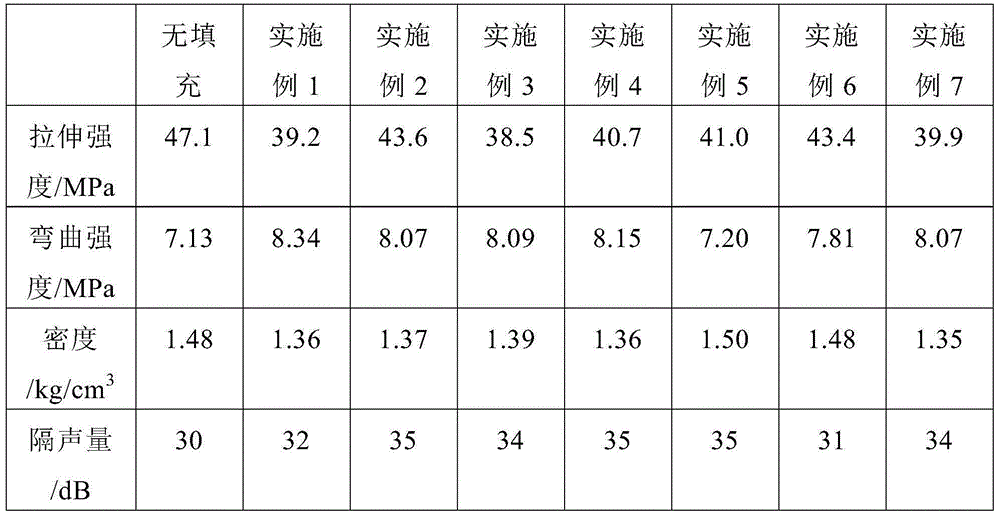

Examples

Embodiment 1

[0028] The preparation technology of the hollow microsphere of coating elastomer, comprises the following steps:

[0029] 1) 90 kg of glass hollow microspheres are placed at the bottom of the fluidized bed reaction chamber;

[0030] 2) Inject air from the gas inlet at the bottom of the fluidized bed reaction chamber, and adjust the airflow to 1.5m3 / h, so that the hollow microspheres are in a suspended state;

[0031] 3) Mix 10kg of acrylate and 0.2kg of 4,4-dimethyl-diphenyliodonium hexafluorophosphate evenly;

[0032] 4) The mixed raw materials are placed in the storage chamber on the upper part of the ebullated bed reaction chamber, and sprayed into the ebullated bed reaction chamber by the atomizing nozzle;

[0033] 5) Turn on the ultraviolet lamp installed above the fluidized bed reaction chamber to irradiate for about 60s;

[0034] 6) The elastic resin coated on the hollow microspheres is cured rapidly under the irradiation of ultraviolet light, the ultraviolet lamp is ...

Embodiment 2

[0036] The preparation technology of the hollow microsphere of coating elastomer, comprises the following steps:

[0037] 1) 40 kg of glass hollow microspheres are placed at the bottom of the fluidized bed reaction chamber;

[0038] 2) Open and inject air from the gas inlet of the fluidized bed reaction chamber, and adjust the air flow to 1.0m3 / h, so that the hollow microspheres are in a suspended state.

[0039] 3) Mix 60kg of polyurethane acrylate resin, 2kg of vinyl silane coupling agent, 0.2kg of stearic acid, and 0.2kg of triphenylthione hexafluorophosphate;

[0040] 4) The mixed raw materials are placed in the storage chamber at the upper part of the fluidized bed reaction chamber, and sprayed into the fluidized bed reaction chamber through the atomizing nozzle.

[0041] 5) Turn on the ultraviolet lamp installed above the fluidized bed reaction chamber to irradiate for about 60s;

[0042] 6) The elastic resin coated on the hollow microspheres is cured rapidly under the...

Embodiment 3

[0046] The preparation technology of the hollow microsphere of coating elastomer, comprises the following steps:

[0047] 1) 90 kg of ceramic hollow microspheres are placed at the bottom of the fluidized bed reaction chamber;

[0048] 2) Open and inject air from the gas inlet of the fluidized bed reaction chamber, and adjust the air flow to 1.8m3 / h, so that the hollow microspheres are in a suspended state.

[0049] 3) Mix 40kg of polyurethane acrylate resin, 2kg of vinyl silane coupling agent, 0.2kg of stearic acid, and 0.2kg of benzoin ether;

[0050] 4) The mixture of elastic resin, coupling agent and surfactant is placed in the storage chamber on the upper part of the ebullated bed reaction chamber, and is sprayed into the ebullated bed reaction chamber by the atomizing nozzle.

[0051] 5) Turn on the ultraviolet lamp installed above the fluidized bed reaction chamber to irradiate for about 60s;

[0052] 6) The elastic resin coated on the hollow microspheres is cured rapi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com