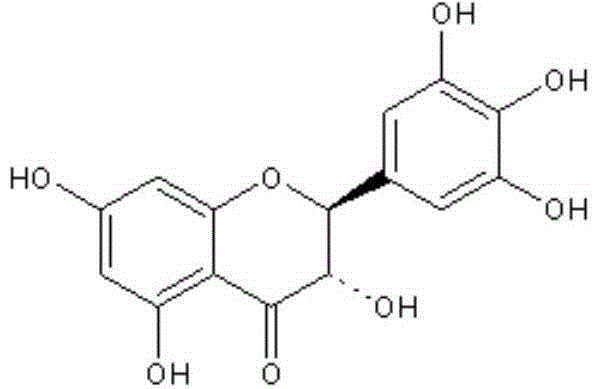

Method for increasing yield of dihydromyricetin in ampelopsis grossedentata

A technology of Snake-toothed Grape and dihydromyricetin, which can be used in pharmaceutical formulations, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of high cost and low efficiency of dihydromyricetin extraction, and improve the market Supply, Increased Extraction Yield, Effect of Economic Extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

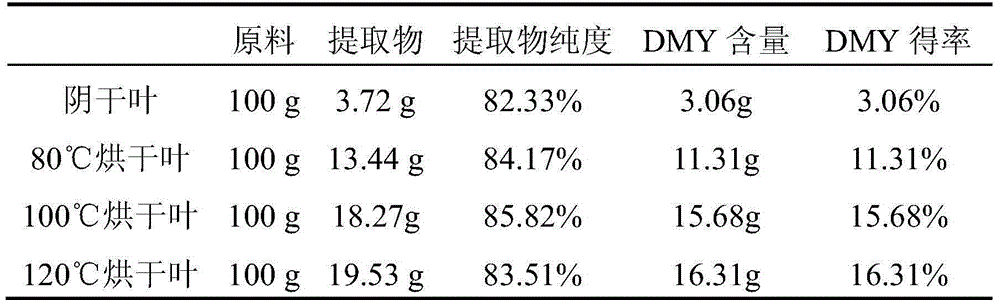

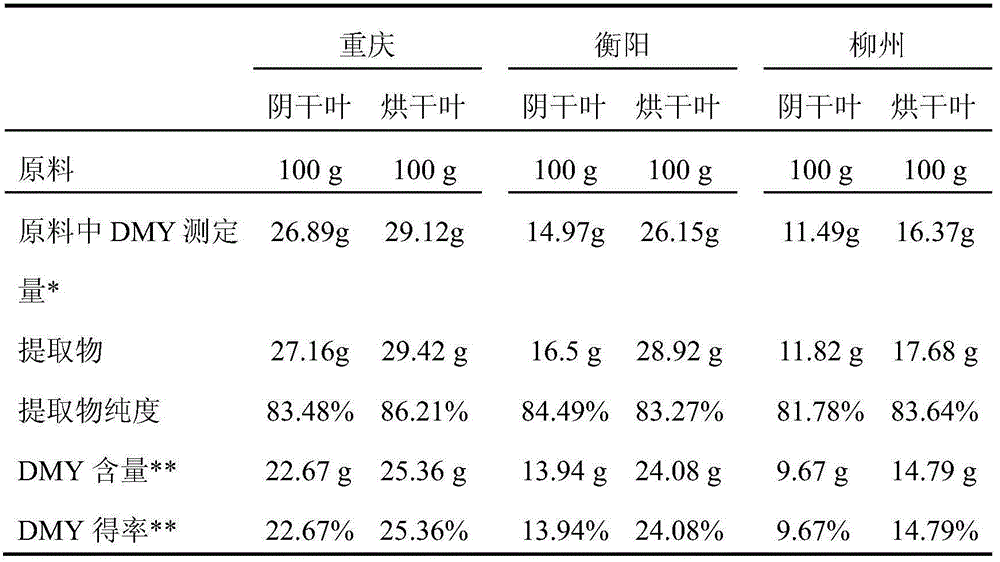

Embodiment 1

[0041] The method for improving the yield of dihydromyricetin in Snake dentata grape comprises the following steps:

[0042] 1) Picking fresh leaves from the experimental field of Snake-tooth grape in Wuhan, Hubei, and baking the leaves of Snake-toothed grape at a temperature of 80°C for 2 hours;

[0043] 2) pulverize the dry-processed Snake Grapes, pass through a 40-mesh sieve to obtain Snake Grapes powder, and set aside;

[0044] 3) Weighing 100g of Eperodonta grape powder and adding it to 2000mL ethanol solution with a volume fraction of 75%, ultrasonically extracting for 30min, and filtering to obtain dihydromyricetin extract;

[0045] 4) Put the dihydromyricetin extract prepared in step 3) in a rotary evaporator, concentrate under reduced pressure in a water bath at a temperature of 50°C, recover ethanol until it has no alcohol smell, add 1000mL of boiling water to dissolve, and put it in a low temperature environment at 4°C. Cold crystallization, filtration, and drying ...

Embodiment 2

[0047] The method for improving the yield of dihydromyricetin in Snake dentata grape comprises the following steps:

[0048] 1) Picking fresh leaves from the experimental garden of Snake-tooth grape in Wuhan, Hubei, and baking the leaves of Snake-toothed grape at a temperature of 100°C for 1.5 hours;

[0049] 2) pulverize the dry-processed Snake Grapes, pass through a 40-mesh sieve to obtain Snake Grapes powder, and set aside;

[0050] 3) Weighing 100g of Eperodonta grape powder and adding it to 2000mL ethanol solution with a volume fraction of 75%, ultrasonically extracting for 30min, and filtering to obtain dihydromyricetin extract;

[0051] 4) Put the dihydromyricetin extract prepared in step 3) in a rotary evaporator, concentrate under reduced pressure in a water bath at a temperature of 50°C, recover ethanol until it has no alcohol smell, add 1000mL of boiling water to dissolve, and put it in a low temperature environment at 4°C. Cold crystallization, filtration, and dry...

Embodiment 3

[0053] The method for improving the yield of dihydromyricetin in Snake dentata grape comprises the following steps:

[0054] 1) Picking fresh leaves from the experimental field of Snake-tooth grape in Wuhan, Hubei, and baking the leaves of Snake-tooth grape at a temperature of 120°C for 1 hour;

[0055] 2) pulverize the dry-processed Snake Grapes, pass through a 40-mesh sieve to obtain Snake Grapes powder, and set aside;

[0056] 3) Weighing 100g of Eperodonta grape powder and adding it to 2000mL ethanol solution with a volume fraction of 75%, ultrasonically extracting for 30min, and filtering to obtain dihydromyricetin extract;

[0057] 4) Put the dihydromyricetin extract prepared in step 3) in a rotary evaporator, concentrate under reduced pressure in a water bath at a temperature of 50°C, recover ethanol until it has no alcohol smell, add 1000mL of boiling water to dissolve, and put it in a low temperature environment at 4°C. Cold crystallization, filtration, and drying of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com